Heat dissipating sheet and temperature regulating device

A technology of temperature regulating device and heat sink, applied in heat exchange equipment, heat exchanger shell, lighting and heating equipment, etc., can solve the problems of poor heat flow, poor adaptability, complicated manufacturing process, etc. Structural stability, good heat flow effect, and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

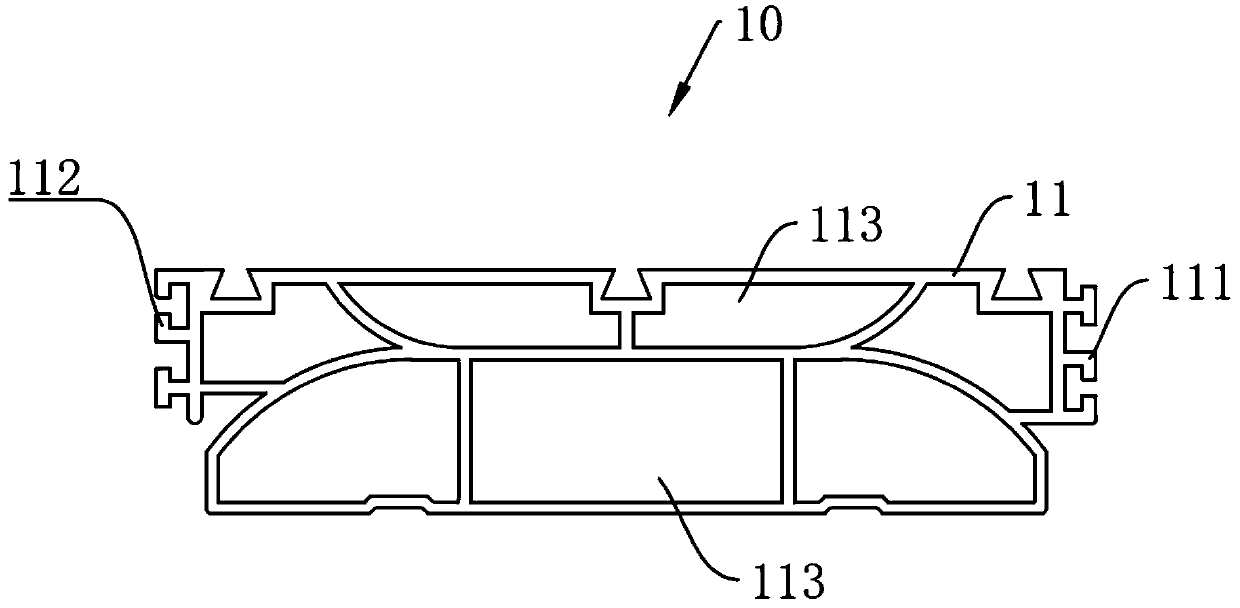

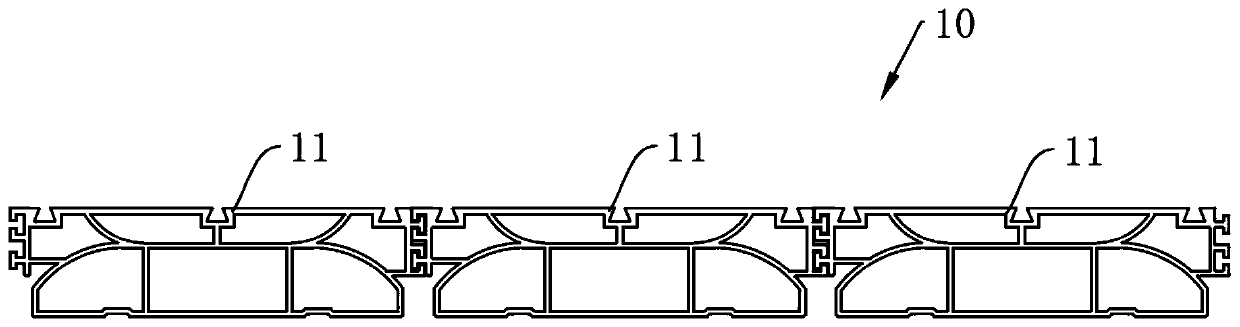

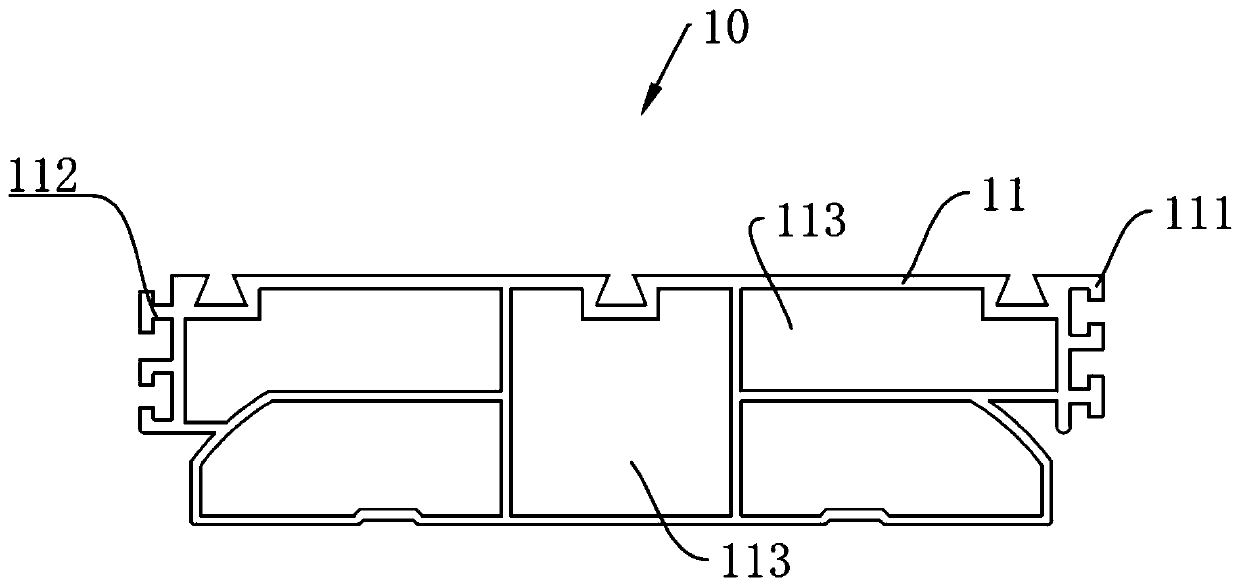

[0063] Please also refer to figure 1 and figure 2 , this embodiment provides a heat sink 10, which can be applied to the outside or surface of various objects that need heat exchange, thereby accelerating the heat exchange efficiency of the object and rapidly dissipating the heat of the object. It includes a heat sink body 11, There is at least one heat sink body 11 . The heat sink body 11 is formed with a convection chamber 113 penetrating therethrough, and a first connecting portion 111 and a second connecting portion 112 that cooperate with each other are formed on both sides, and the first connecting portion 111 can be passed between the two heat sink bodies 11 It is connected with the second connecting portion 112 .

[0064] The heat sink body 11 is in the shape of a sheet. In this embodiment, it is a straight rectangular sheet / plate. In other embodiments, the heat sink body 11 may be a sheet with a curved surface or a bent surface. The convection cavity 113 on the he...

Embodiment 2

[0083] Please also refer to Figure 4 and Figure 5 The difference between the heat sink 10 of this embodiment and the body of the heat sink 10 of Embodiment 1 is that, in addition to the convection cavity 113, a plurality of heat dissipation fins 114 are formed on the heat dissipation fin body 11, and the extension of the heat dissipation fins 114 is consistent with The convection chambers 113 extend in the same direction.

[0084] In this way, the heat sink body 11 can not only have better heat flow, but also have a larger heat dissipation area, and can maximize the heat flux and heat radiation effect in a limited area. In this case, no heat build-up will occur. The heat sink body 11 has the same cross-section in the length direction, and can be integrally formed by extrusion, so that the processability is better.

[0085] The structure of the heat sink body in this embodiment is as follows: remove the outer wall of the first layer of the three convection chambers 113 of ...

Embodiment 3

[0089] Please also refer to Figure 6 to Figure 8 In addition to the heat sink body 11 and / or the heat sink body 11 of Embodiment 1 and / or the heat sink body 11 of Embodiment 2, the heat sink 10 of this embodiment also includes a functional barrier 12, and a first connecting portion is provided on both sides of the functional barrier 12 111 and the second connection part 112.

[0090]In this way, the functional barrier 12 can be spliced with the heat sink body 11, and the functional barrier 12 connected to the heat sink body 11 can be used as an extension and combination to expand the space, and can also be used as a fixed load-bearing component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com