Heat insulation material and method for preparing heat insulation shell from same

A technology of thermal insulation and thermal insulation, applied in the direction of coating, etc., can solve the problems of poor thermal insulation effect, fragility, poor appearance of thermal insulation materials, etc., and achieve the effect of improving thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

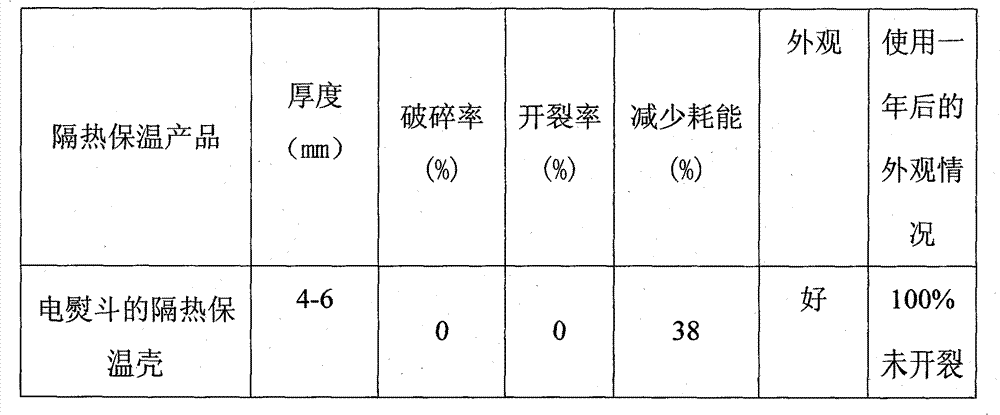

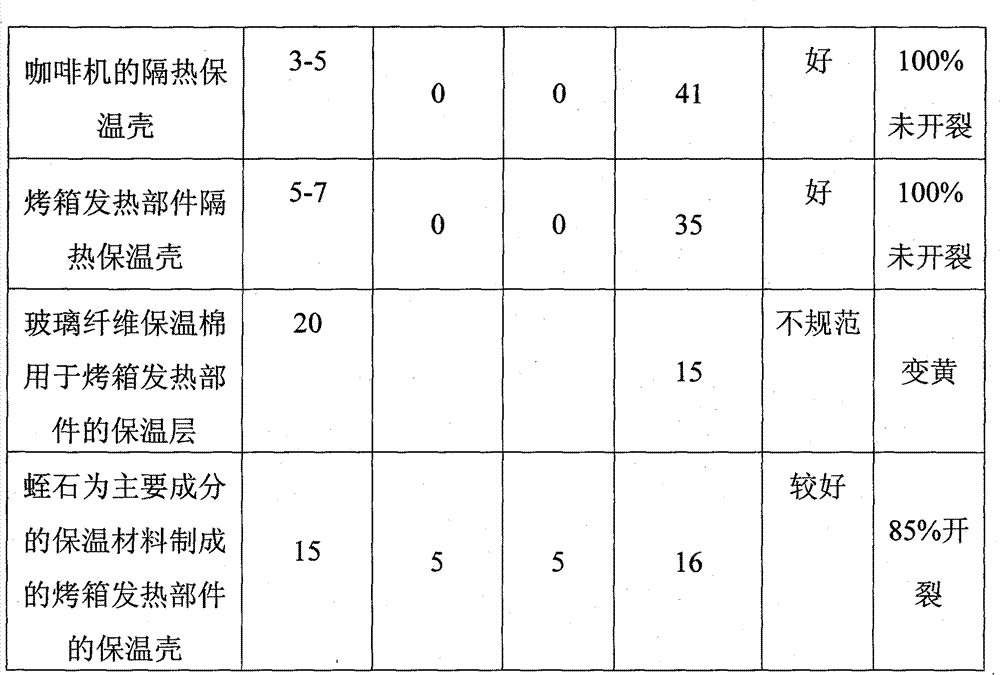

Examples

Embodiment 1

[0027] 257.71 grams of glass fiber, 257.87 grams of water, 6.45 grams of methyl cellulose, 22.03 grams of vinyl acetate and ethylene copolymer, 44.05 grams of bentonite, 85.9 grams of vermiculite, 28.63 grams of foaming agent, and 257.71 grams of thermosetting amino resin.

[0028] Preparation method: Add the above components into a mixer and mix and stir for later use.

Embodiment 2

[0030] 257.71 grams of glass fiber, 258.87 grams of water, 5.45 grams of methyl cellulose, 25.03 grams of vinyl acetate and ethylene copolymer, 41.05 grams of bentonite, 85.9 grams of vermiculite, 28.63 grams of foaming agent, and 257.71 grams of thermosetting amino resin.

[0031] Preparation method: Add the above components into a mixer and mix and stir for later use.

Embodiment 3

[0033] 237.71 grams of glass fiber, 257.87 grams of water, 6.45 grams of methyl cellulose, 22.03 grams of vinyl acetate and ethylene copolymer, 44.05 grams of bentonite, 105.9 grams of vermiculite, 28.63 grams of foaming agent, and 257.71 grams of thermosetting amino resin.

[0034] Preparation method: Add the above components into a mixer and mix and stir for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com