A linear spectral confocal system for three-dimensional surface measurement

A three-dimensional surface and linear technology, applied in the field of measuring instruments, can solve the problems of inconspicuous spectral separation and small measurement depth, and achieve the effect of realizing spectral separation, large depth measurement range, and simple and fast measurement method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the structure, features and advantages of the present invention clearer, the present invention will be described in further detail in conjunction with the accompanying drawings, but it should not be construed as limiting the protection scope of the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

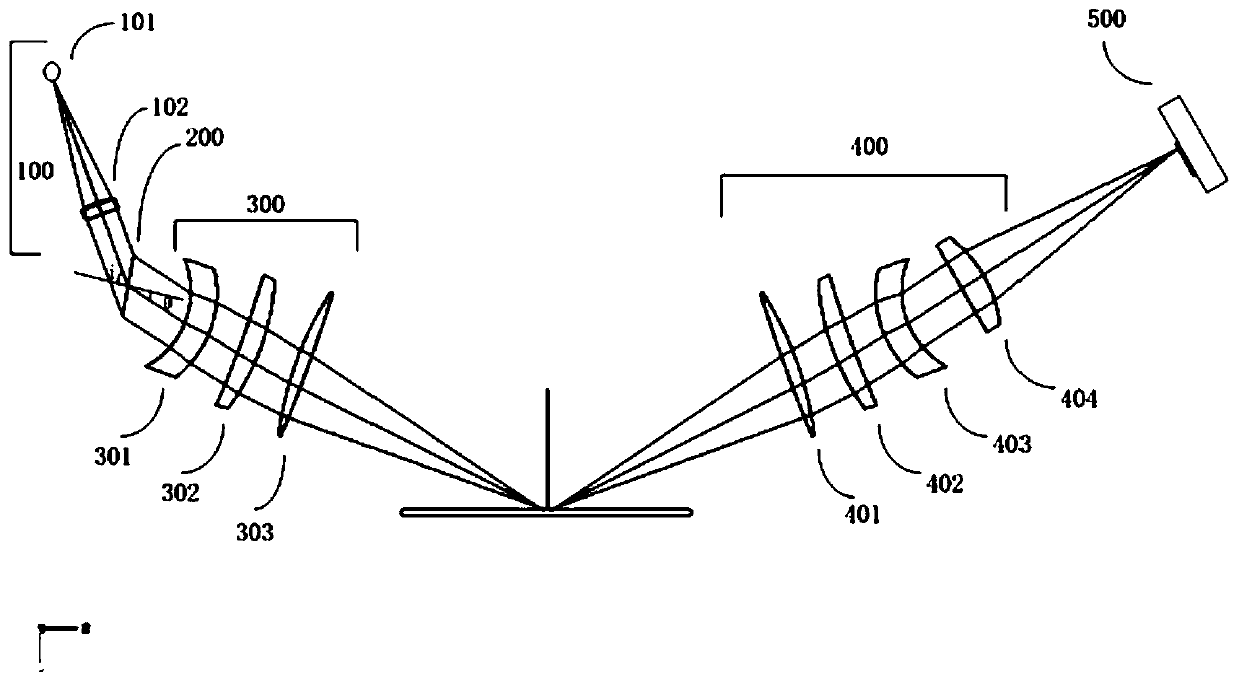

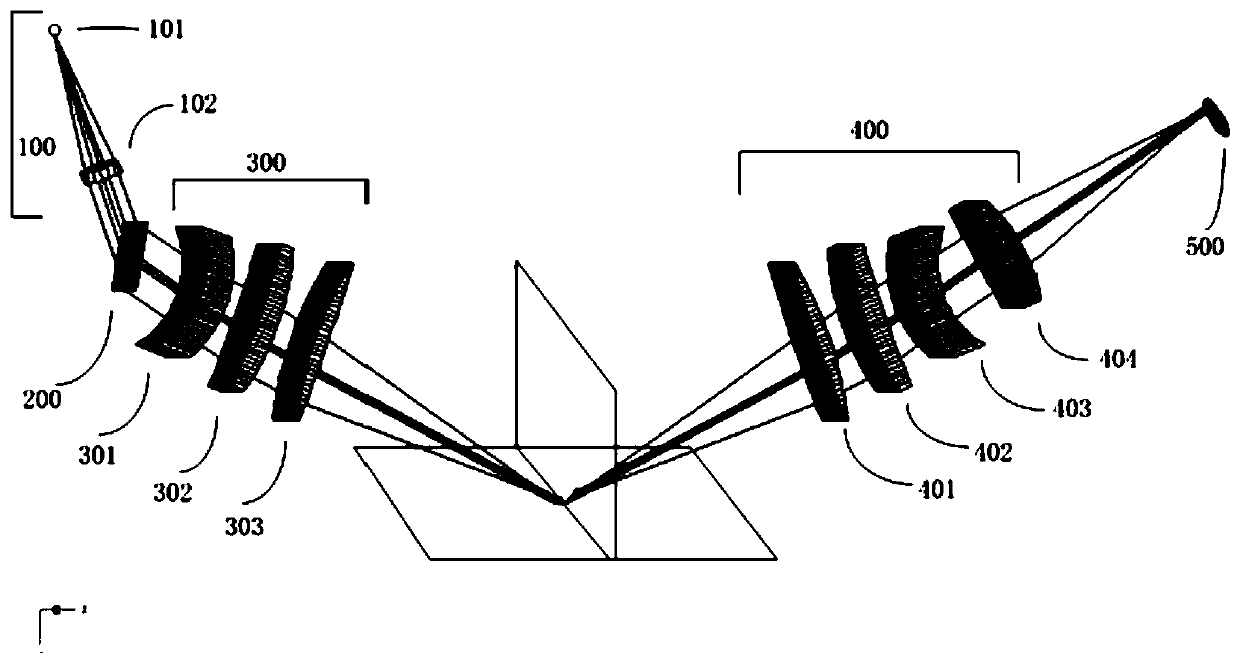

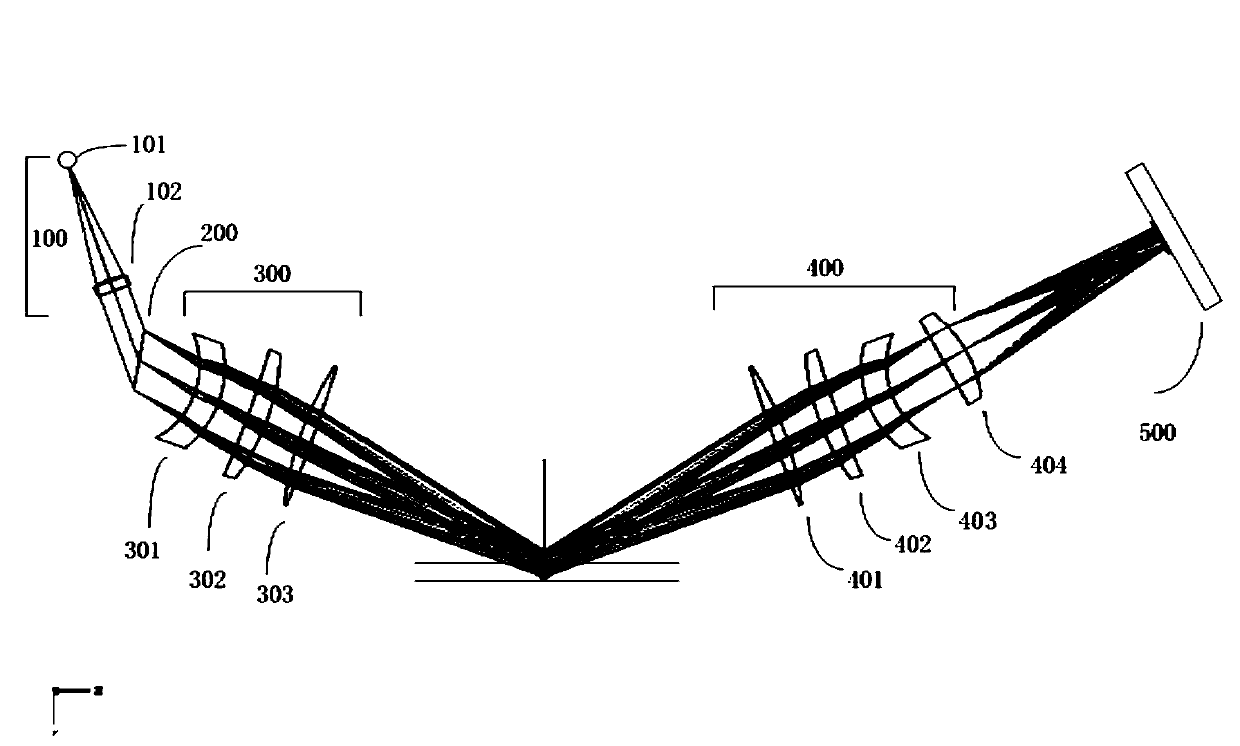

[0032] figure 1 It is a schematic diagram of the specific structure of the linear spectral confocal system of the present invention. The linear spectral confocal system includes: a radiation source 100 , a transmission grating 200 , a cylindrical lens group 300 , an optical radiation processing unit 400 and a detector 500 .

[0033] The radiation light source (100) is a wide-spectrum LED (101) with a color temperature of about 5000K, which can provide uniform light radiation with a wavelength of 500-600nm. The wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com