Piezoelectric driving ultra-precision four-degree-of-freedom positioning and attitude adjusting mechanism and excitation method thereof

A piezoelectric drive, ultra-precision technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve complex structures and excitation methods, high prices, piezoelectric Poor stacking tensile capacity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

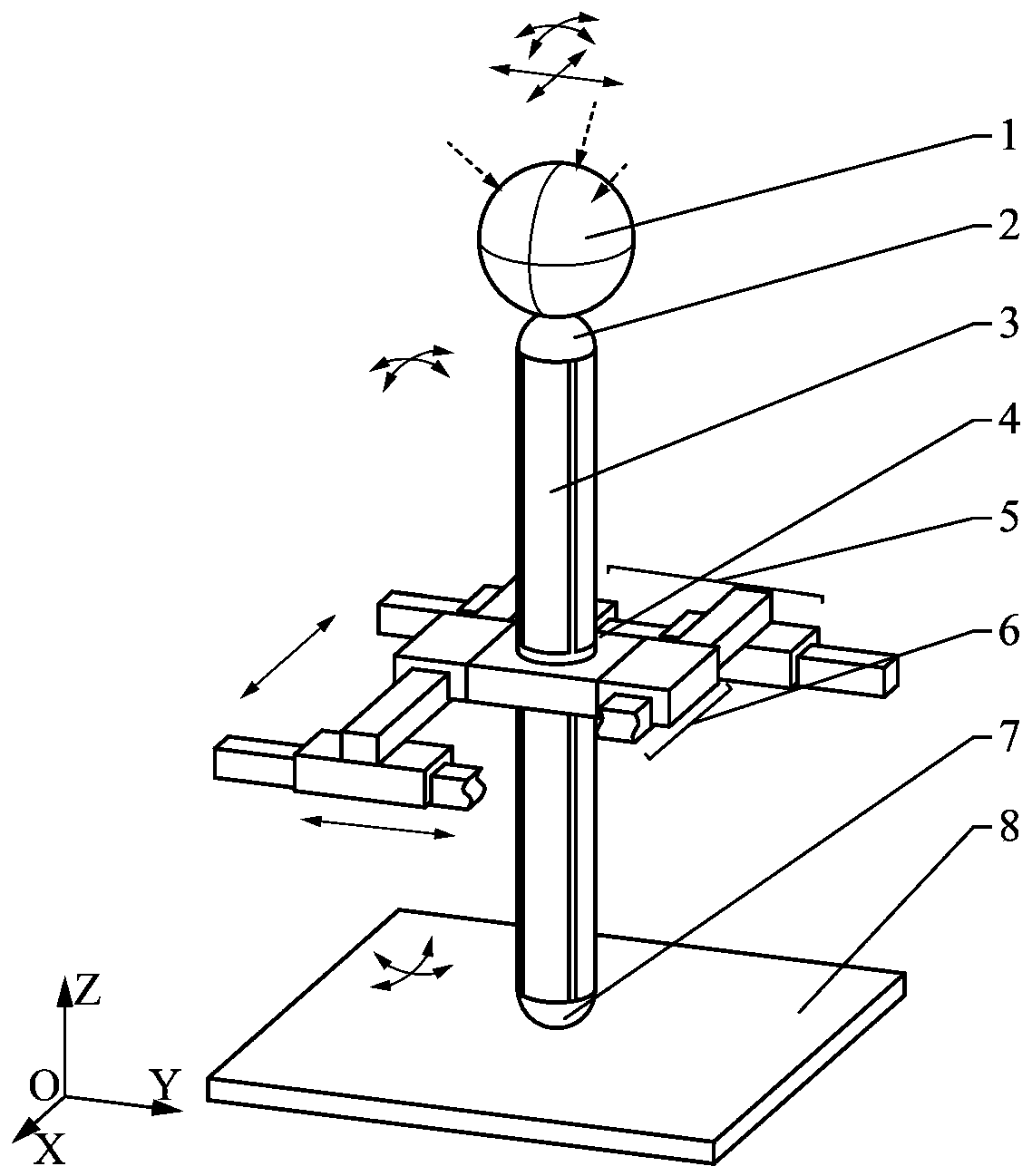

[0063] The following is attached with the instruction manual figure 1 , figure 2 , image 3 , Figure 4 This embodiment will be described in further detail. This embodiment provides a method such as figure 1 The ultra-precision four-degree-of-freedom positioning and attitude adjustment mechanism using piezoelectric ceramic tubes as the main driving element is shown. The positioning and posture adjustment mechanism includes a mover 1, an upper driving foot 2, a piezoelectric ceramic tube 3, a fixed clamp block 4, a transverse guide rail 5, a longitudinal guide rail 6, a lower driving foot 7 and a base 8; 8 Keep it fixed. figure 1 The axial direction of the medium piezoelectric ceramic tube 3 is the Z-axis direction, the horizontal direction orthogonal to the axial direction of the piezoelectric ceramic tube 3 is the Y-axis direction, and the depth direction orthogonal to the axial direction of the piezoelectric ceramic tube 3 is the X-axis The directions, in the following embod...

specific Embodiment 2

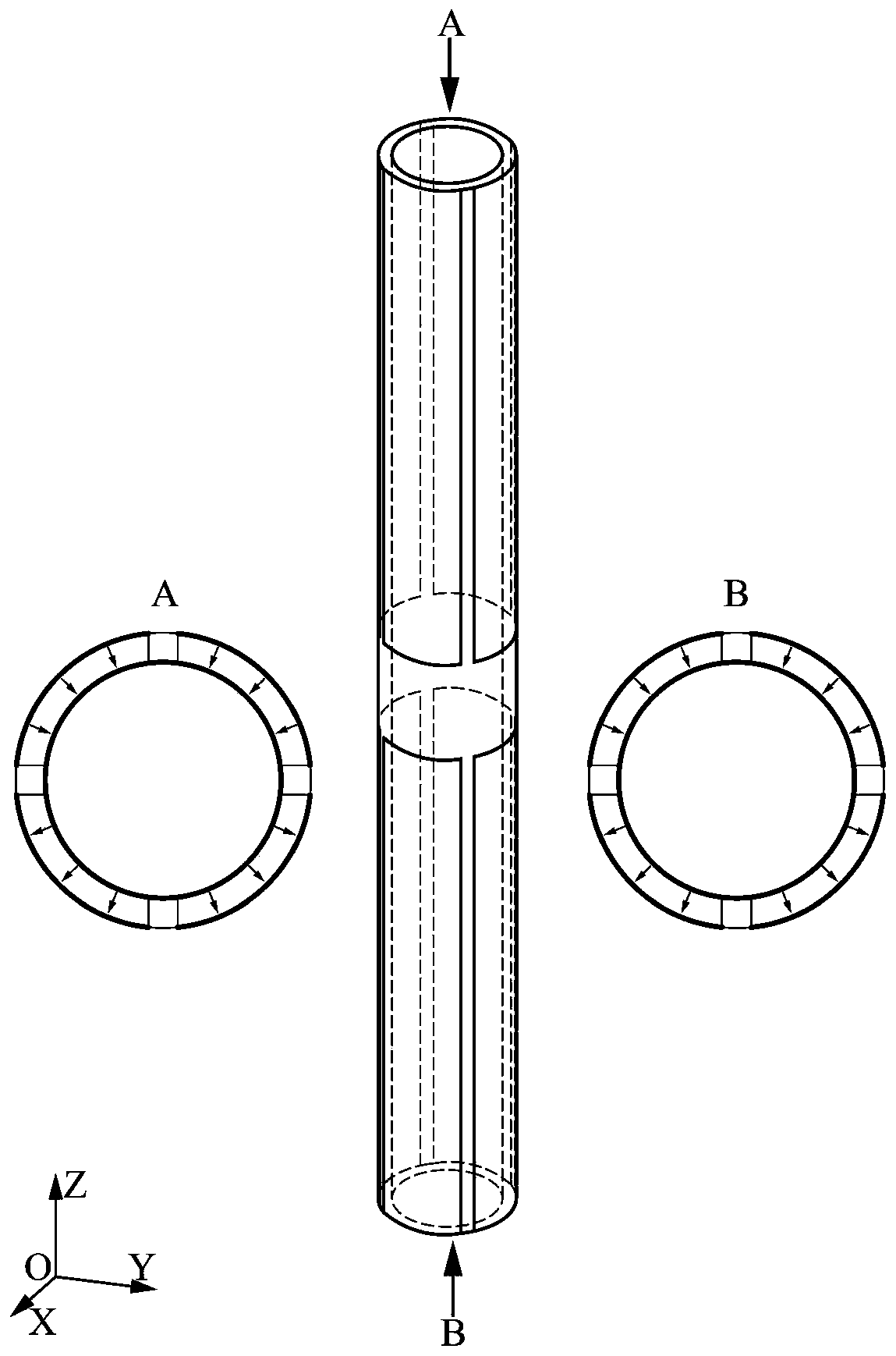

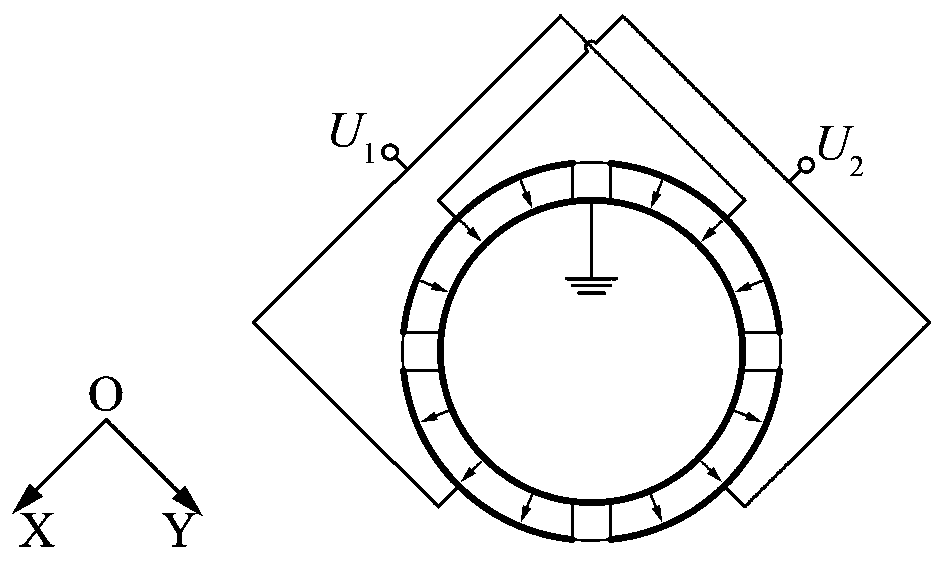

[0068] The following is attached with the instruction manual figure 1 , figure 2 , image 3 , Figure 5 , Image 6 , Figure 7 This embodiment will be described in further detail. This embodiment provides a method based on figure 1 The excitation method of the ultra-precision four-degree-of-freedom positioning and attitude adjustment mechanism shown in the figure can realize the large-scale four-degree-of-freedom ultra-precision movement of mover 1, including linear movement along the X-axis or Y-axis and around the X-axis or The rotational movement in the Y-axis direction can achieve nanometer resolution by adjusting the amplitude and time of the excitation voltage signal. In this embodiment, the polarization direction of each partition of the piezoelectric ceramic tube 3 is as follows: figure 2 As shown, the method of applying excitation voltage signal to each partition electrode of the upper and lower parts is as follows image 3 Shown.

[0069] The excitation method for re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com