Oil sludge screening separating device suitable for coupling effect

A separation device and oil sludge technology, which is applied in the direction of filtration separation, separation method, mobile filter element filter, etc., can solve the problems of low oil sludge efficiency and inability to guarantee oil cleanliness, and achieve the effect of easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

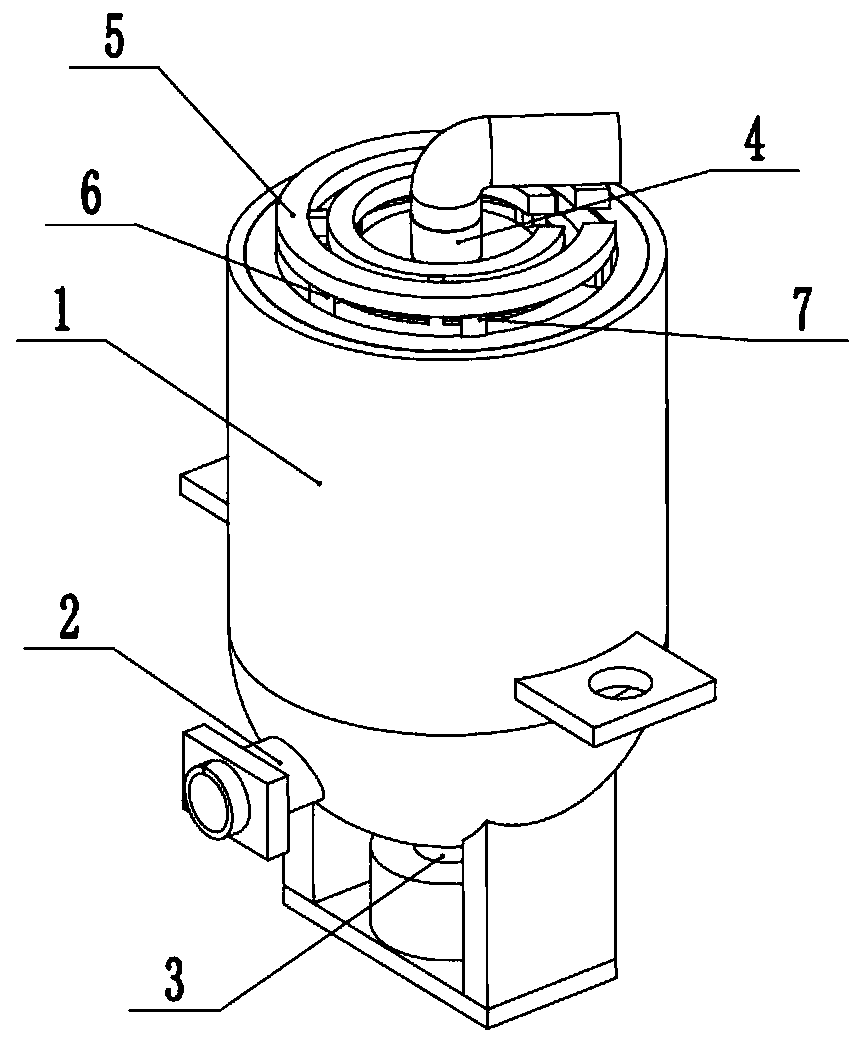

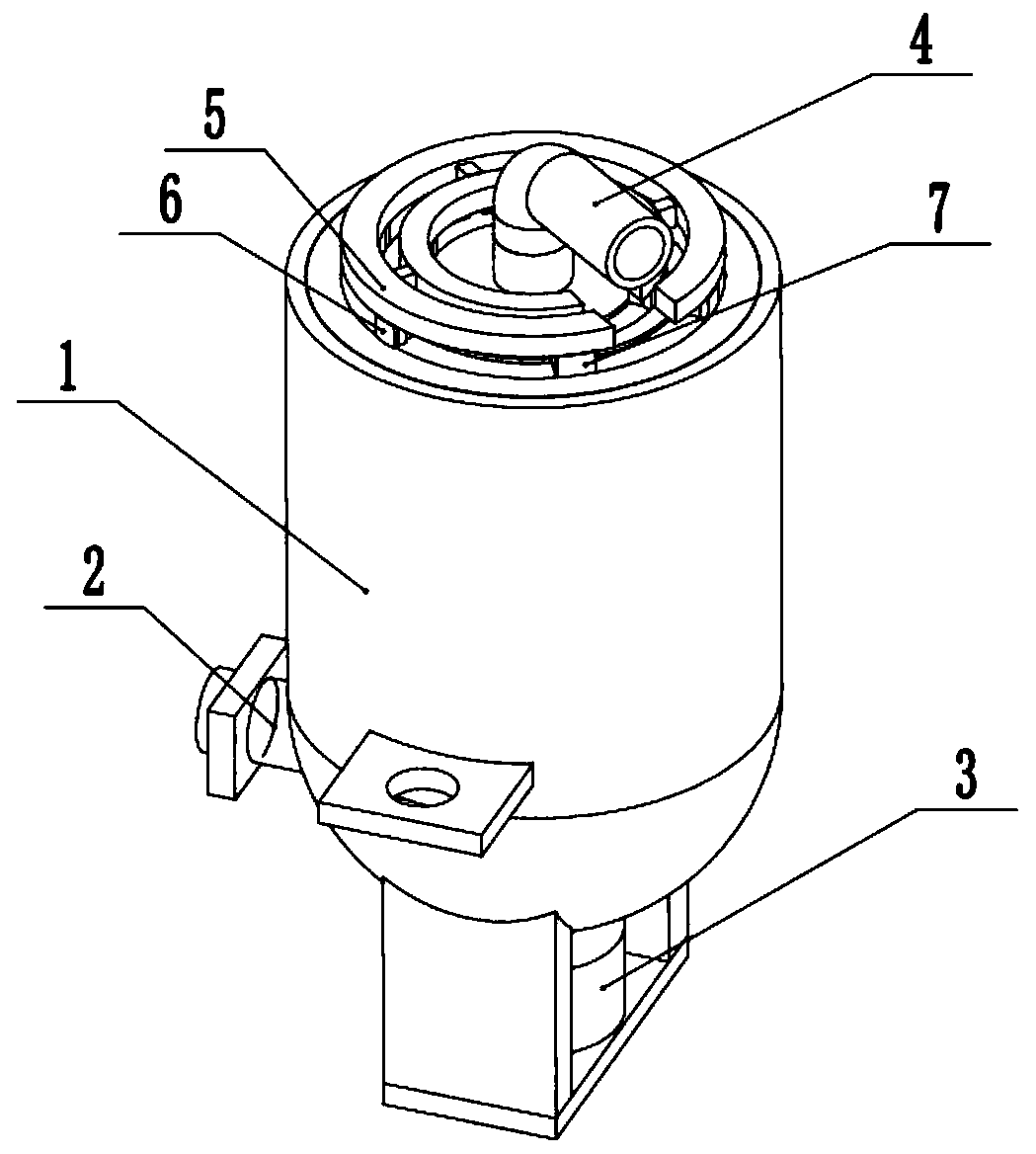

[0030] Such as Figure 1 to Figure 10 As shown in the figure, an oil sludge screening and separation device suitable for coupling, including a sieving fixed cylinder 1, an oil recovery pipe with a valve 2, a centrifugal drive 3, an oil sludge adder 4, a sludge recovery plate 5, and six sludge scrapers 6 and six mud recovery devices 7, the oil recovery pipe 2 with a valve is fixedly connected to the lower side of the left end of the sieve fixed cylinder 1, the oil recovery pipe 2 with a valve is connected to the inside of the sieve fixed cylinder 1, and the centrifugal drive The lower end of 3 is fixedly connected to the sieve-off fixed cylinder 1, the centrifugal driver 3 is rotatably connected in the sieve-off fixed cylinder 1, the oil sludge adder 4 is fixedly connected to the upper end of the sieve-off fixed cylinder 1, and the upper end of the centrifugal driver 3 is rotatably connected to the sludge In the adder 4 , the sludge recovery plate 5 is fit in the upper end of t...

specific Embodiment approach 2

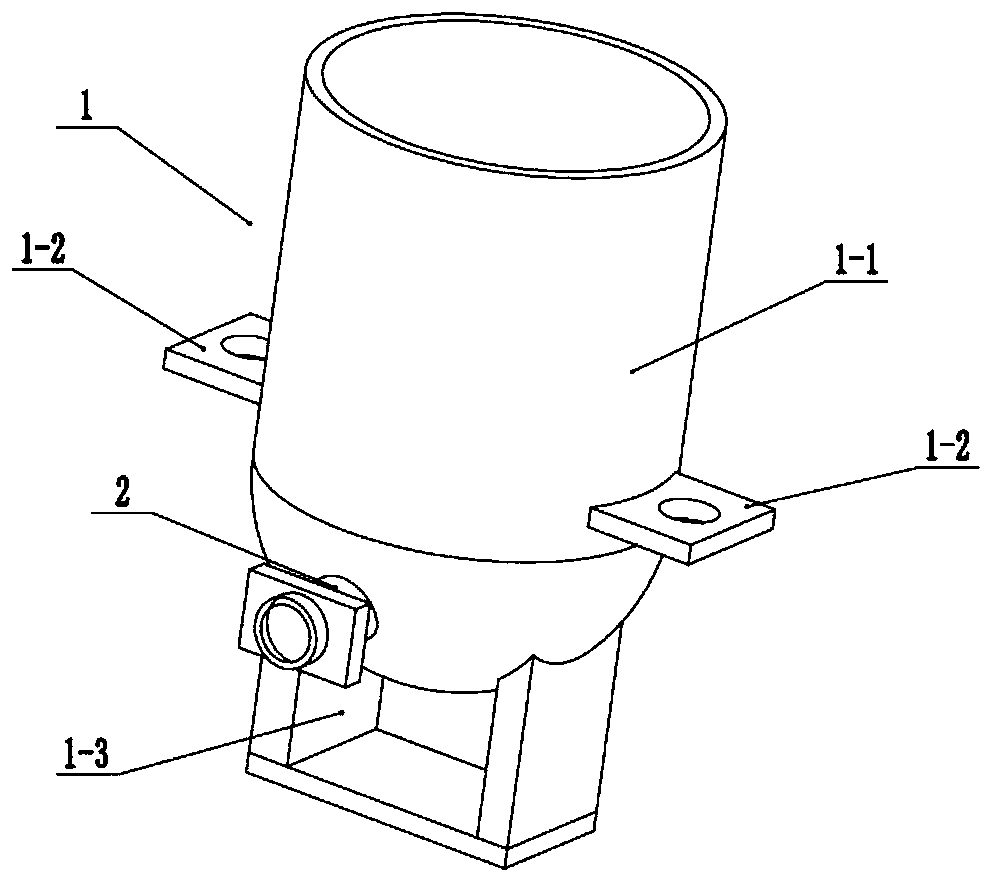

[0032] Such as Figure 1 to Figure 10As shown, this embodiment will further describe Embodiment 1. The described sieving and fixing cylinder 1 includes a sieving and separating cylinder body 1-1, two fixing plates 1-2 and a motor fixing seat 1-3, and two fixing plates 1 -2 are respectively fixedly connected to the two ends of the outer wall of the sieving cylinder 1-1, the two fixing plates 1-2 are provided with threaded holes, and the motor fixing seat 1-3 is fixedly connected to the lower end of the sieving cylinder 1-1 . The two fixing plates 1-2 fix the device by bottom corner bolts.

specific Embodiment approach 3

[0034] Such as Figure 1 to Figure 10 As shown, this embodiment will further explain the second embodiment. The centrifugal driver 3 includes a servo motor 3-1, a central rotating shaft 3-2, a precision separation screen filter cartridge 3-3, and a plurality of precision separation round holes 3- 4. Particle separation sieve cartridge 3-5 and multiple particle separation holes 3-6, servo motor 3-1 is fixedly connected in the motor fixing seat 1-3, the lower end of the central rotating shaft 3-2 is connected to the servo through a coupling The transmission shaft of the motor 3-1 and the central rotating shaft 3-2 are rotationally connected to the lower end of the sieving cylinder 1-1 through a mechanical seal, and the lower end of the precision separation sieve filter cartridge 3-3 is fixedly connected to the central rotating shaft 3-2. The separation screen filter cartridge 3-3 is provided with a plurality of penetrating precision separation circular holes 3-4, the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com