Profile bending machine and control system thereof

A technology of control system and bending machine, which is applied in the field of profile processing, can solve the problems of high maintenance cost, inconvenient demoulding of profiles, and inconvenient processing of bending molds, etc., and achieve the effect of simple mold processing, convenient positioning, and accurate mold installation and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

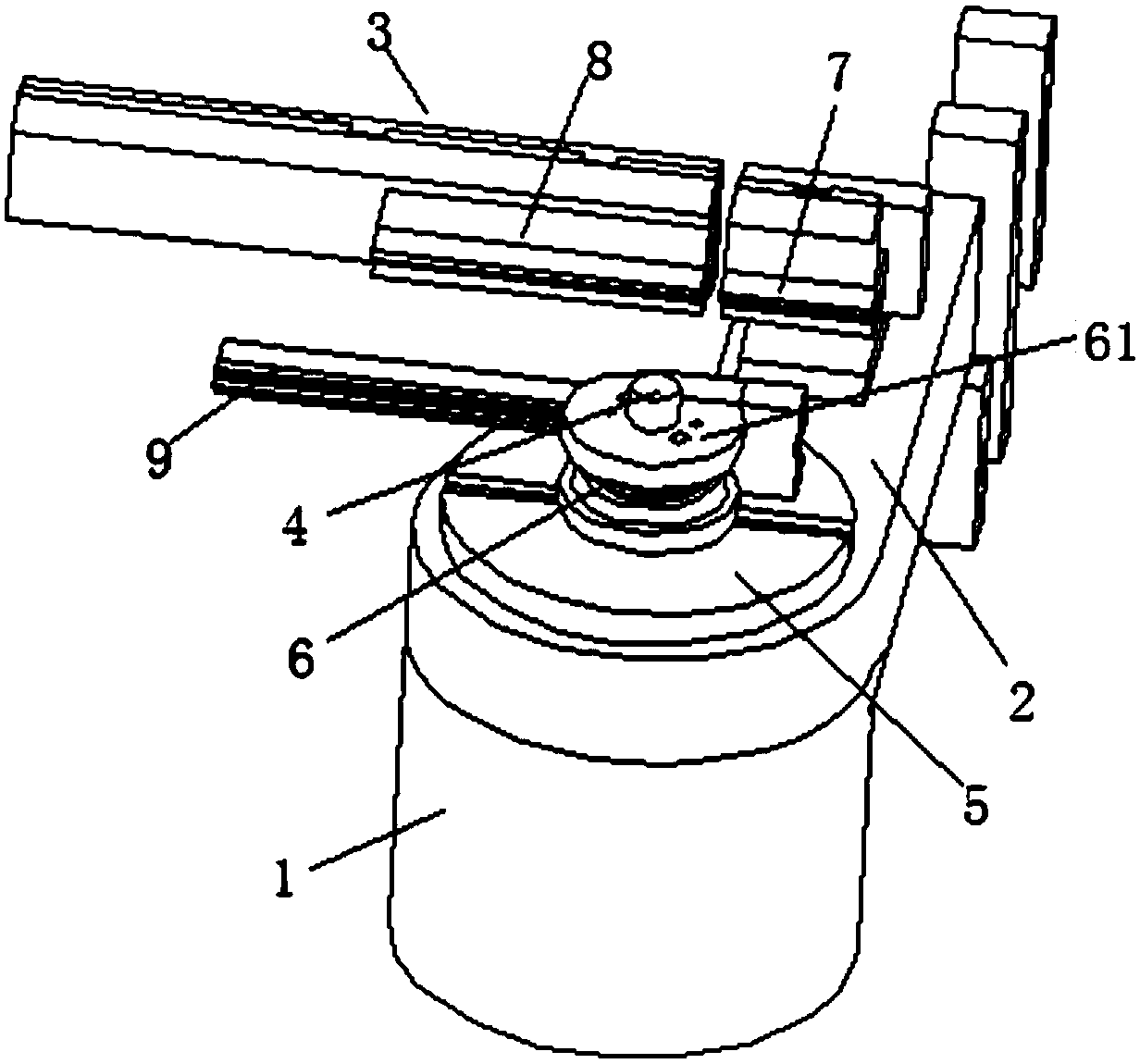

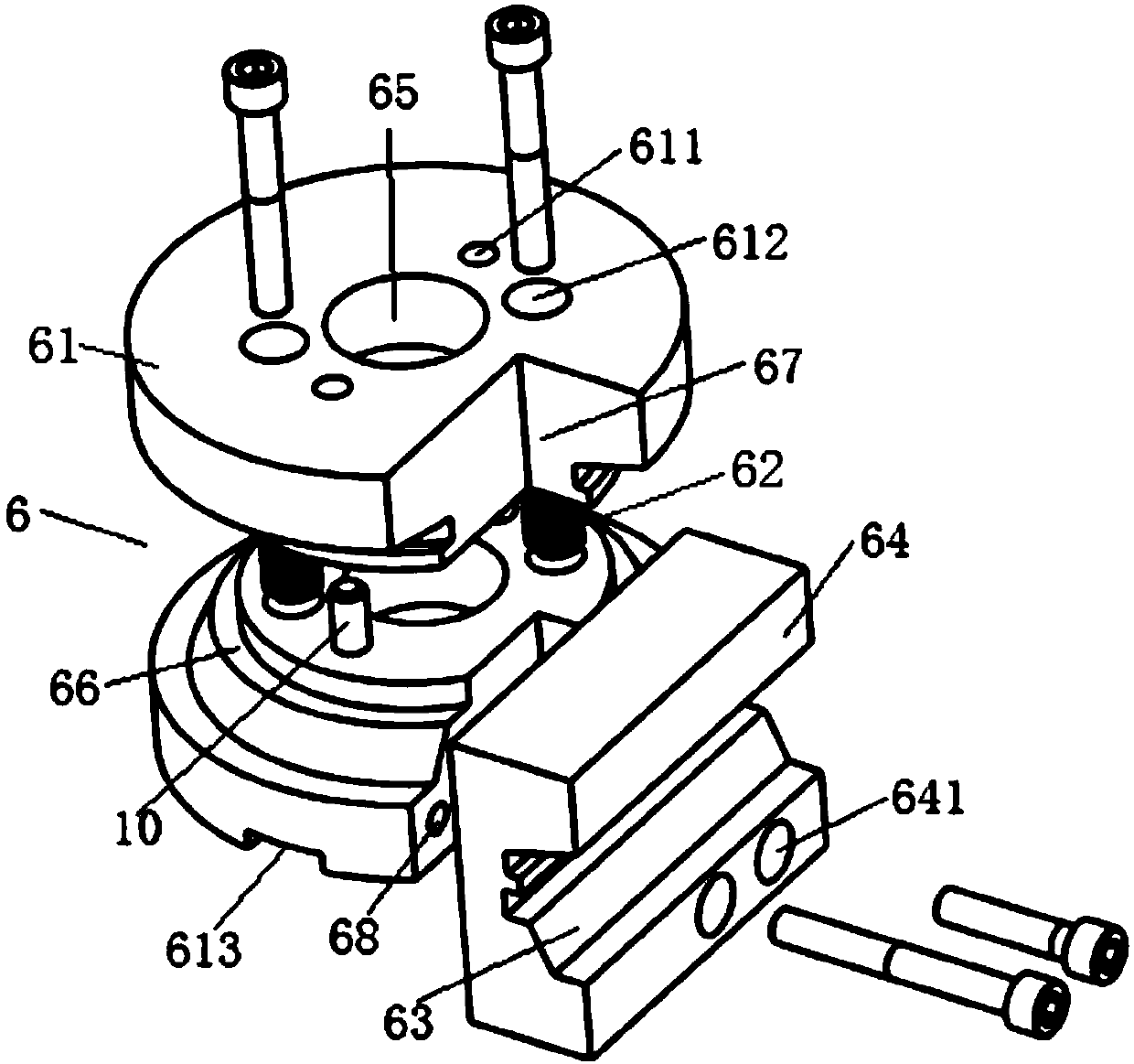

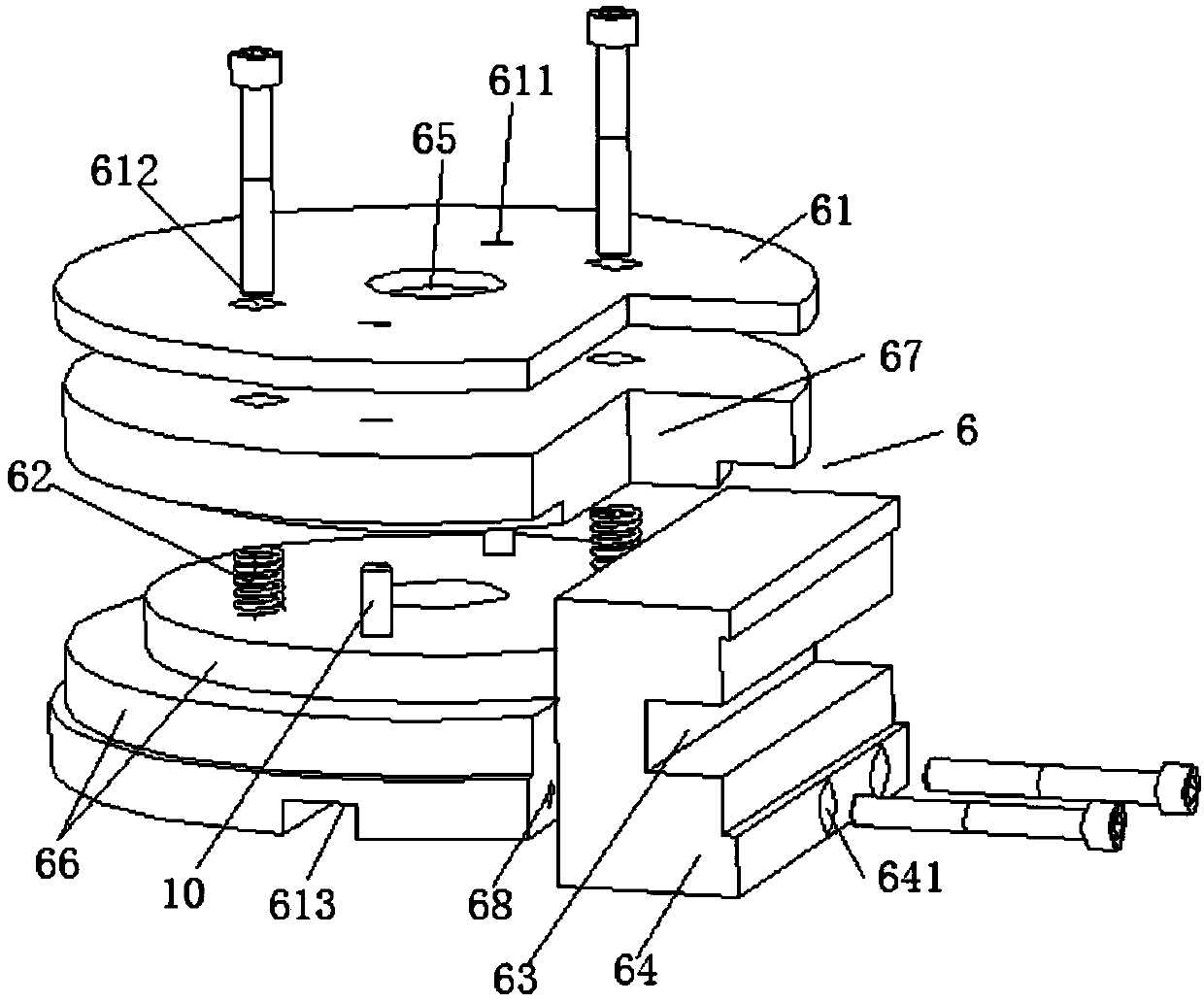

[0030] Such as Figure 1-3 The profile bending machine shown includes a spindle base 1, a rotary table 2, and a follow-up table 3. One end of the rotary table 2 is installed on the spindle base 1 and rotates with the spindle 4. 2. A mold positioning platform 5 set outside the main shaft 4 is set on the upper side. A mold 6 for bending profiles is installed on the top of the mold positioning platform 5. A tool that can move forward and backward toward the main shaft 4 is set on the top of the rotary table 2 outside the mold positioning platform 5. Positioning block 7; before the profile 9 is bent, the positioning block 7 moves toward the main shaft 4 and sticks to the profile 9. During the bending process of the profile 9, the rotating platform 2 rotates with the main shaft 4 and the mold 6, driving the The positioning block 7 rotates, so that the positioning block 7 can locate the bending position of the profile in real time, so as to avoid the deformation of the profile 9 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com