Steering wheel damping module

A shock-absorbing module and steering wheel technology, which is applied to steering control, vehicle safety arrangements, handwheels and other directions installed on the car, can solve the problems of increased difficulty in design, small inner space of the steering wheel, and insufficient air bag shape, etc., to achieve Conducive to frequency adjustment, optimized structure design, and good protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

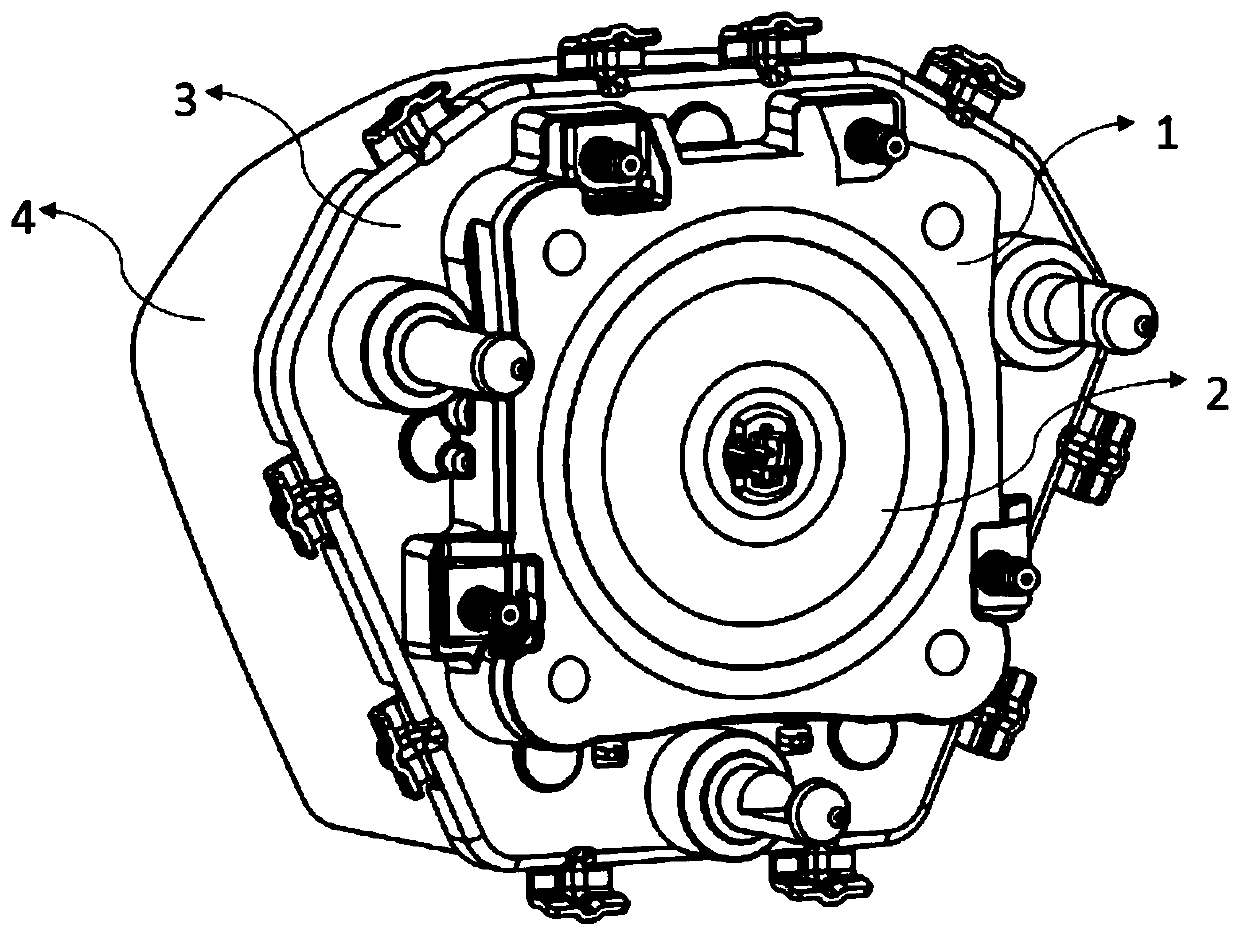

[0026] see figure 1 , the present invention is a steering wheel shock absorbing module, comprising an air bag folding assembly, a shock absorbing unit and a housing assembly, the air bag folding assembly 4 and the housing assembly 3 are fastened and connected by studs, and the shock absorbing unit is fixed Below the housing assembly 3, the shock absorber unit includes a gas generator 2 and a shock absorber 1, the gas generator 2 is arranged in the through hole of the shock absorber 1, and the frequency of the gas generator 2 and the shock absorber 1 is adjusted The gas generator 2 is used as the counterweight of the shock absorber unit, and the frequency adjustment is performed together with the shock absorber 1 .

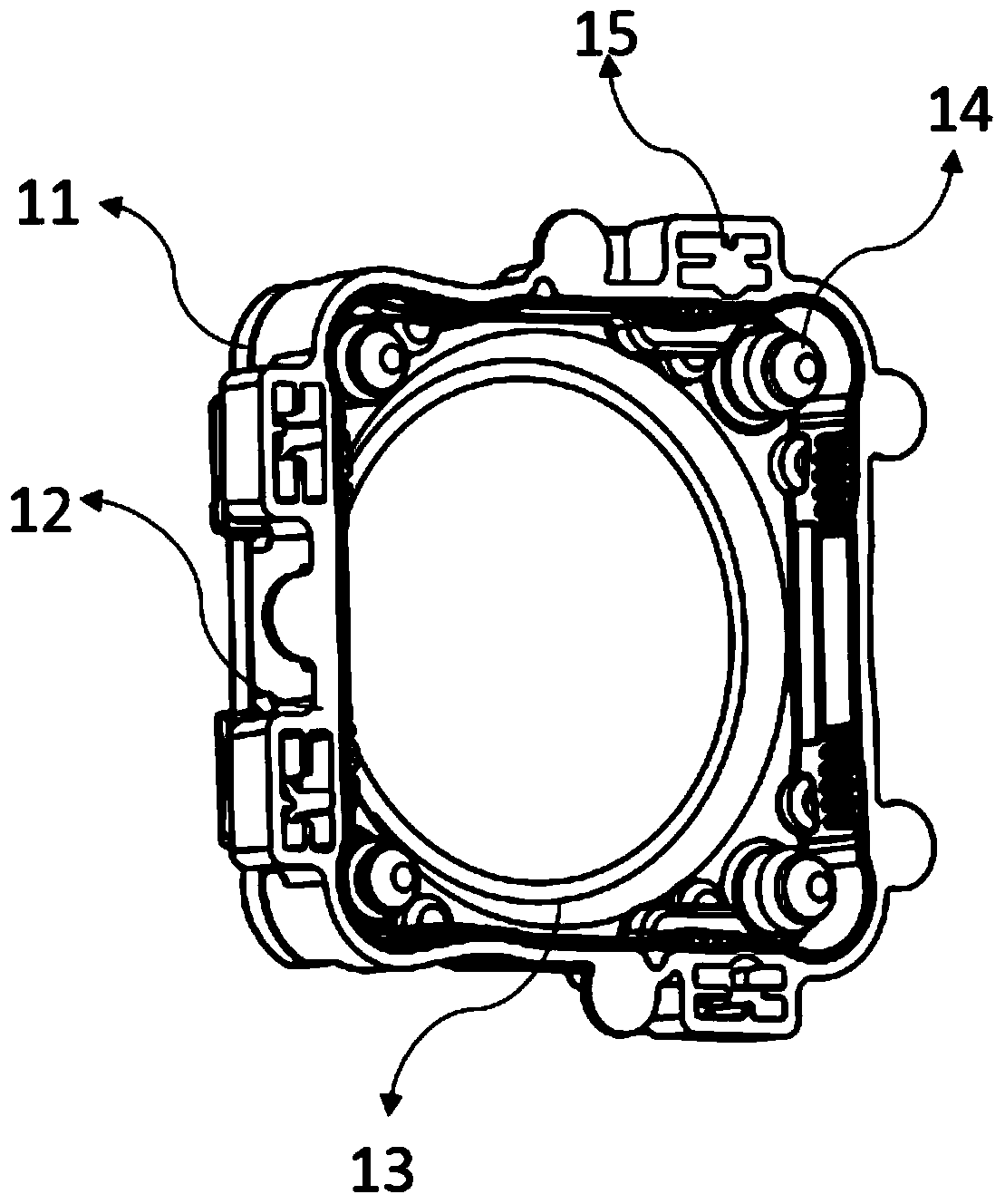

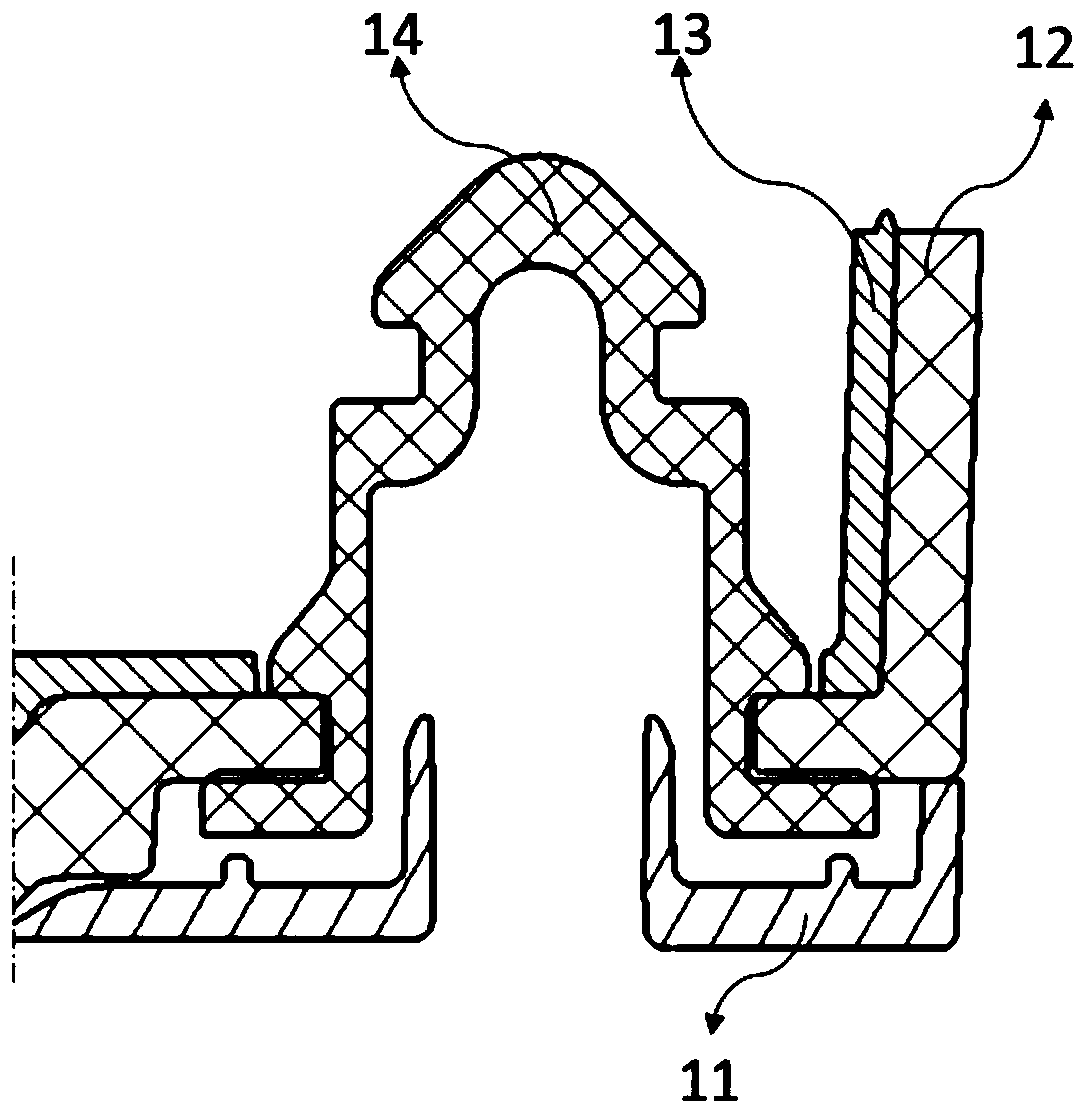

[0027] see figure 2 with image 3 , the shock absorber 1 includes a housing, a frequency regulator 14, and a sealing structure 13, one end of the frequency regulator 14 is embedded in the housing, the other end of the frequency regulator 14 is connected to the g...

Embodiment 2

[0032] During the detonation process of the gas generator 2, the pressure inside the air bag needs to be maintained, and the sealing performance plays a crucial role in the occupant protection performance. The sealing structure 13 can be a sealing groove or a sealing ring. There are two sealing structures 13, one is located at the contact position between the shock absorber 1 and the shell assembly 3 plane, and the other is located at the contact position between the shock absorber 1 and the gas generator. The contact position of the arc surface of the gas generator 2 to ensure the sealing performance of the gas generated by the gas generator 2.

[0033] see Figure 4 , the shock absorber 1 and the housing assembly 3 are closely attached. In order to ensure the sealing performance of the product, the contact position between the sealing structure 13 and the housing assembly 3 is provided with a sealing rib 131, and the sealing rib 131 is higher than that of the housing. The p...

Embodiment 3

[0036] see Image 6 , the lower housing 12 of the shock absorber 1 is provided with a step structure 121, and the corresponding sealing structure 13 is also provided with a raised structure, the step structure 121 is located on both sides of the frequency regulator 14, and the step structure 121 is attached to the gas generator combine. In this example, the frequency adjuster 14 is a silicone head, which is arranged along the axial direction of the gas generator 2 and has a symmetrical structure, and the number of the silicone heads is four or more.

[0037] When the frequency of the damping unit is adjusted, the step structure 121 supports the gas generator 2. At the moment when the gas generator 2 explodes, the gas generator 2 receives a large force while generating gas, and the gas generator 2 is impacted by the gas and Hitting the stepped structure 121, the stepped structure 121 acts as a buffer to prevent the gas generator 2 from directly hitting the shell, causing the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com