Elevator landing door and car door structure which is small in occupied space

A space-occupied, car-door technology that is applied to elevators, transportation, and packaging in buildings. It can solve the problems of large hoistways taking up space and destroying the overall look and feel of fully transparent sightseeing elevators or home elevators, so as to simplify installation and improve The overall look and feel, the effect of reducing the width size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

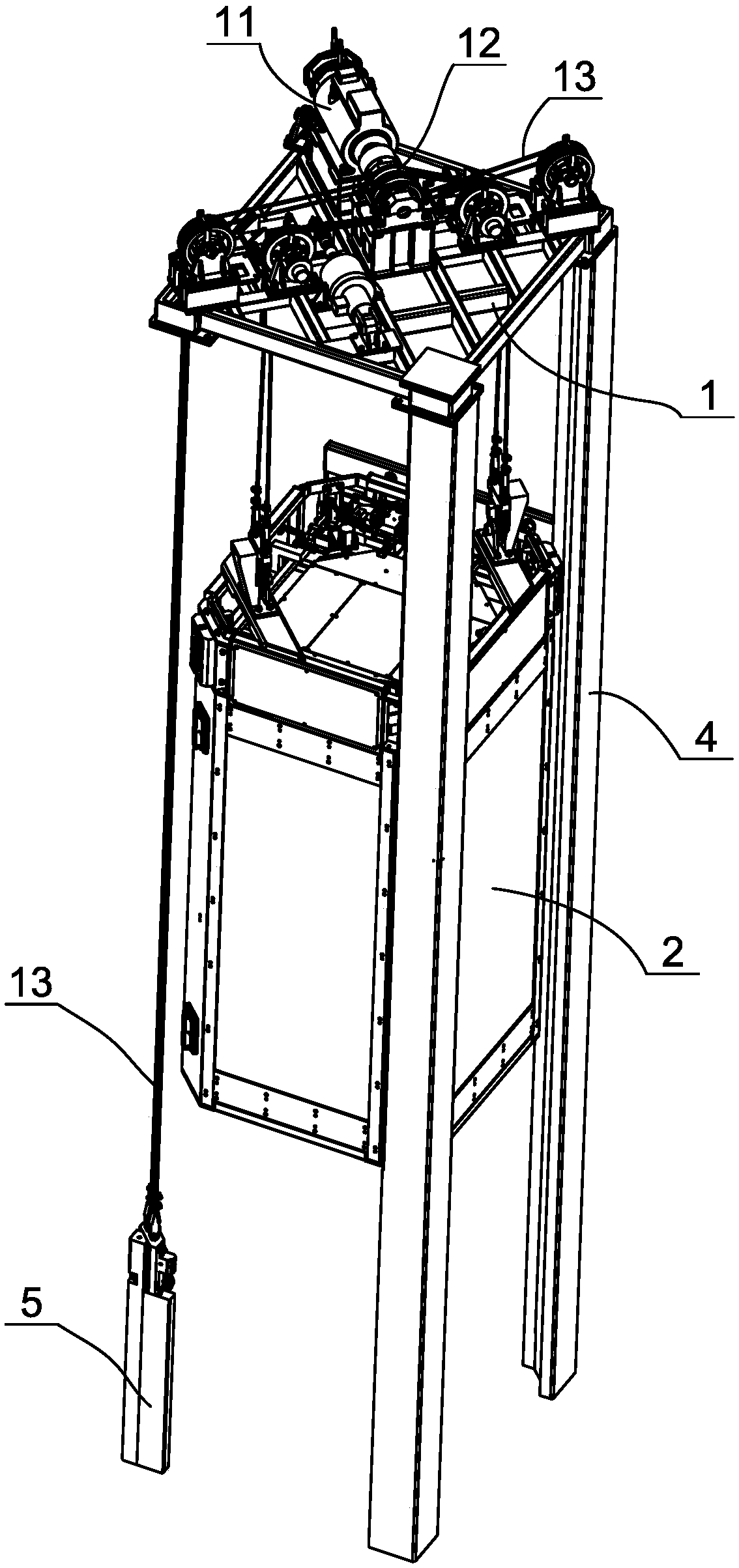

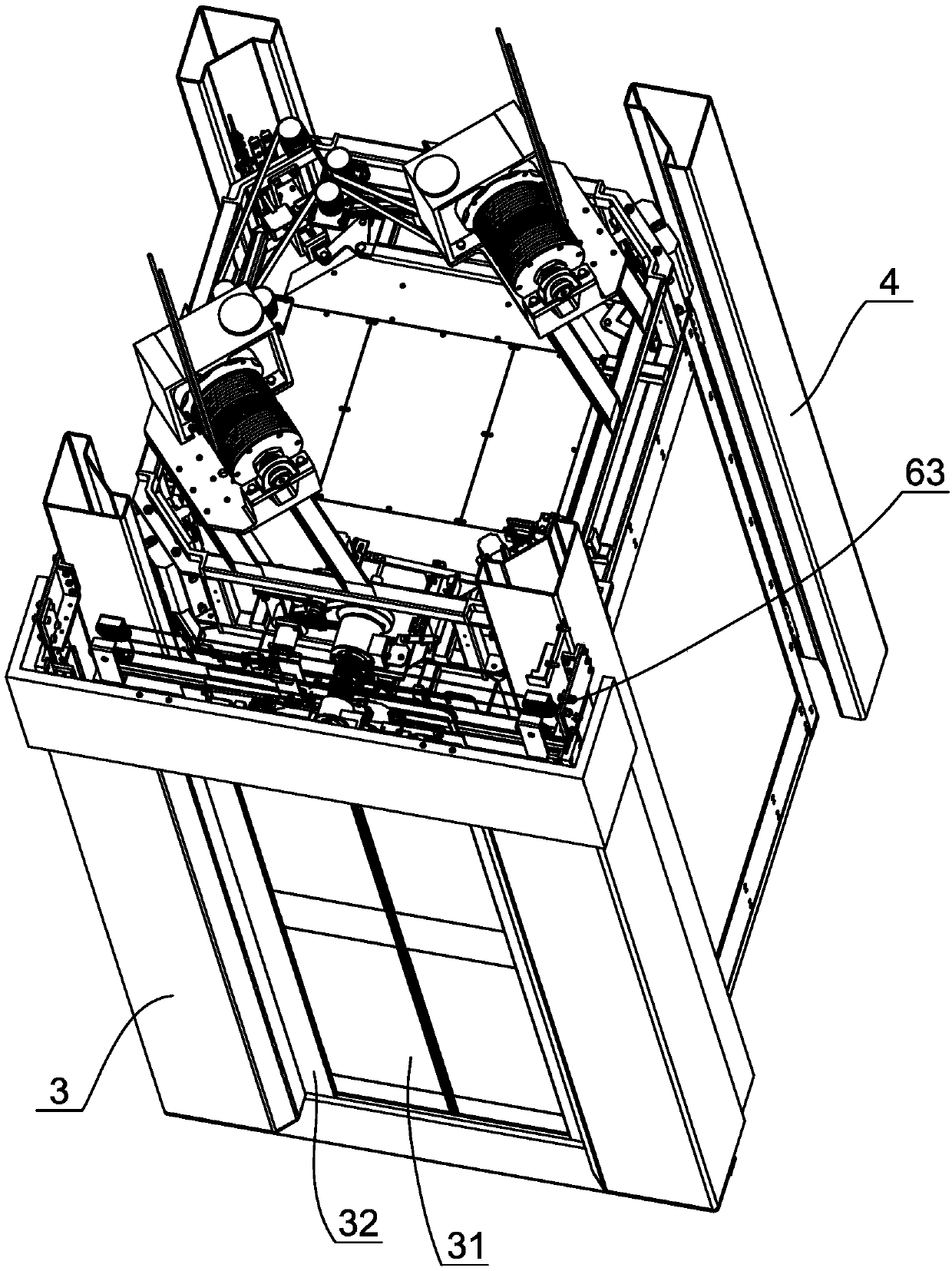

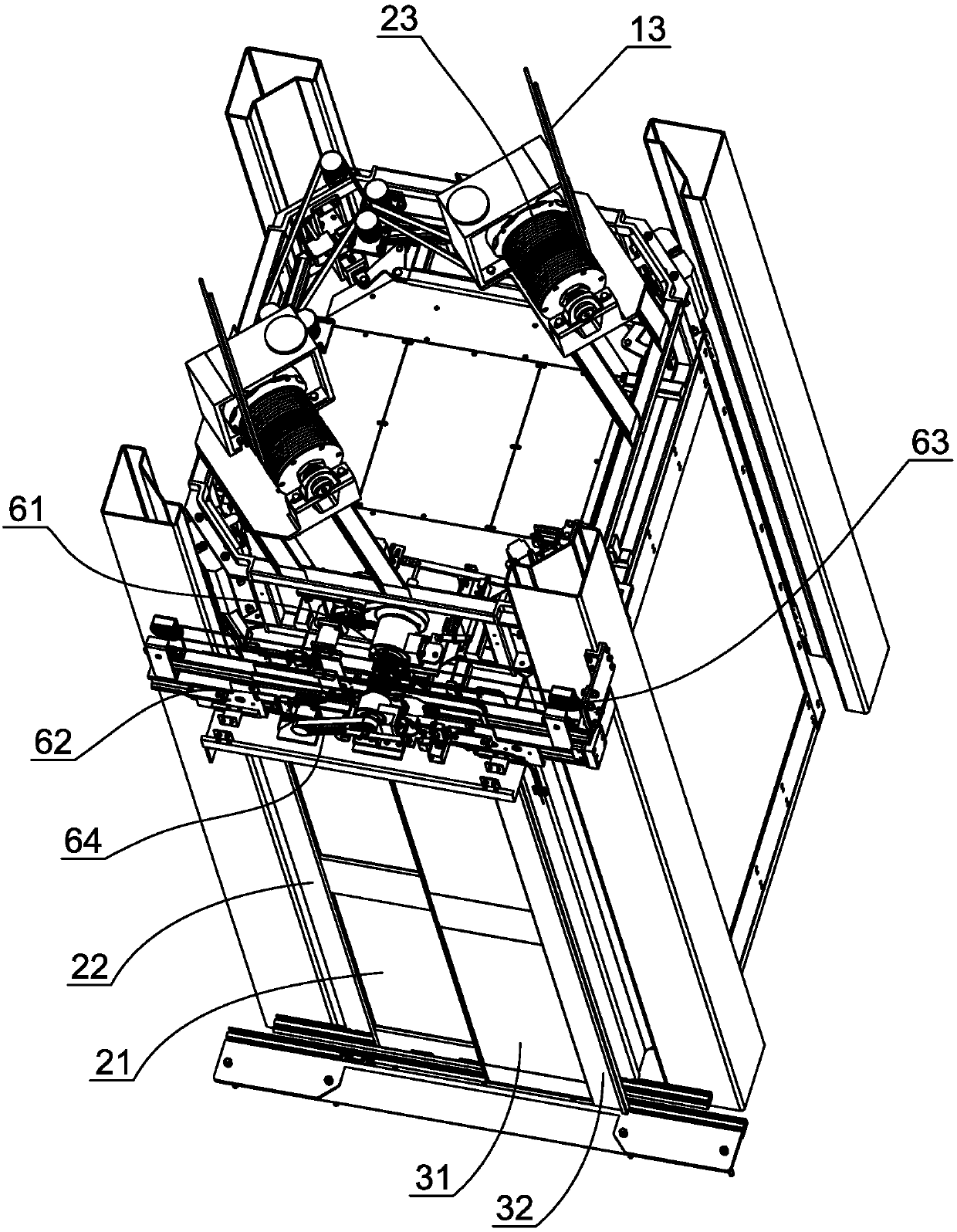

[0033] like figure 1 , figure 2 , image 3 As shown in the figure, an elevator floor door and car door structure with a small footprint includes a traction machine 11 arranged on the installation platform 1 at the top of the elevator shaft, a car 2 with a car door, and a hallway on each floor. The door frame 3 and the landing door movably arranged on the door frame are provided with hoistway columns 4 extending vertically downward at the four corners of the installation platform ( figure 1 2 are not shown), the hoistway column is made of extruded hollow structural profiles, thereby forming a vertical sliding cavity in the hoistway column. Guide rails extending in the axial direction are set on the outside of the hoistway columns, and guide shoes are installed at the four corners of the car between the four hoistway columns, and the guide sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com