Light guide plate applicable to polarized backlight and polarized backlight

A technology of light guide plate and backlight source, applied in the direction of light guide, optics, optical components, etc., to achieve the effect of improving uniformity and uniform and continuous polarized light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the following description, for purposes of explanation and to have a comprehensive understanding of the present invention, numerous specific details are set forth, however, it will be obvious to those skilled in the art that the present invention can be practiced without these specific details. . In other instances, well-known structures and devices are shown in block diagram form. In this regard, the illustrative example embodiments have been presented for purposes of illustration only, and are not intended to be limiting of the invention. Therefore, the protection scope of the present invention is not limited by the above specific embodiments, but only by the scope of the appended claims.

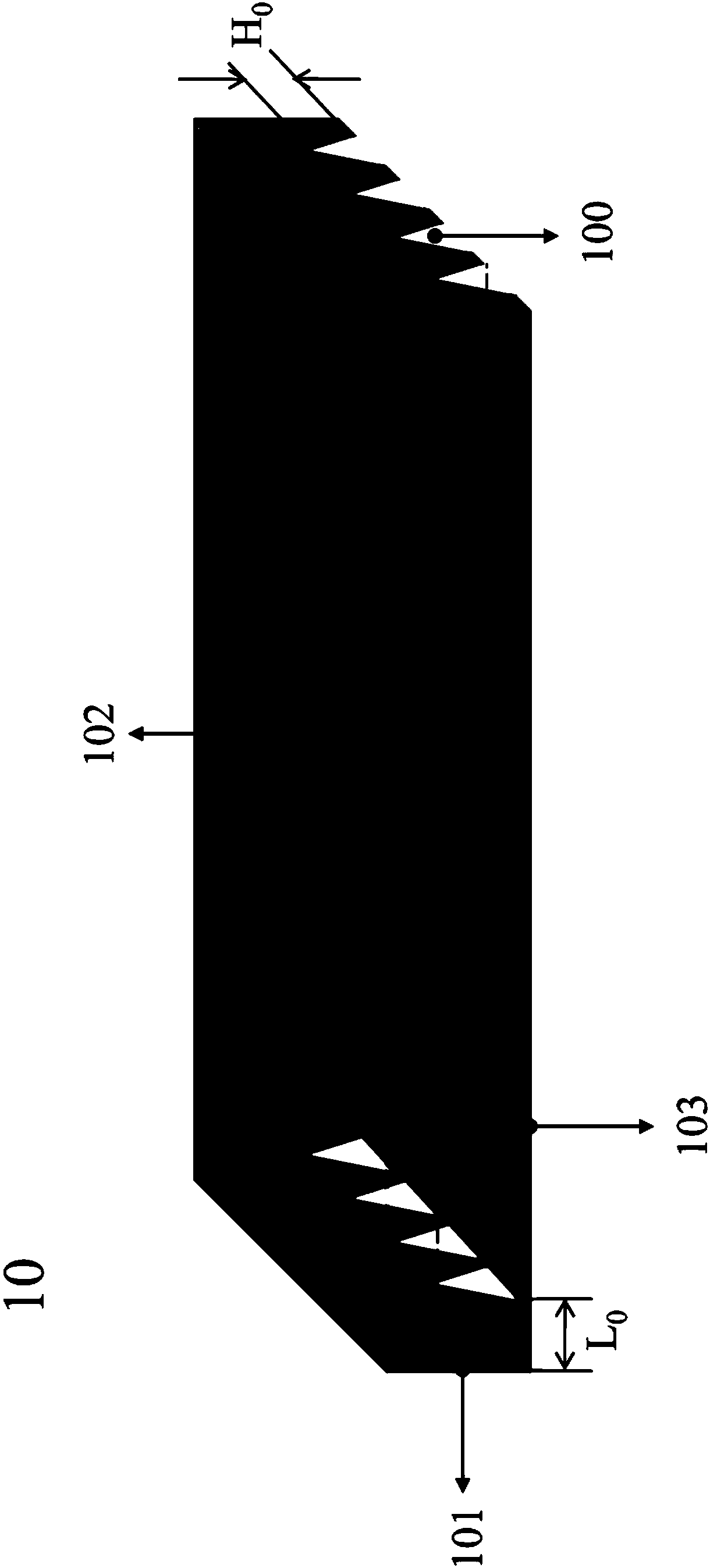

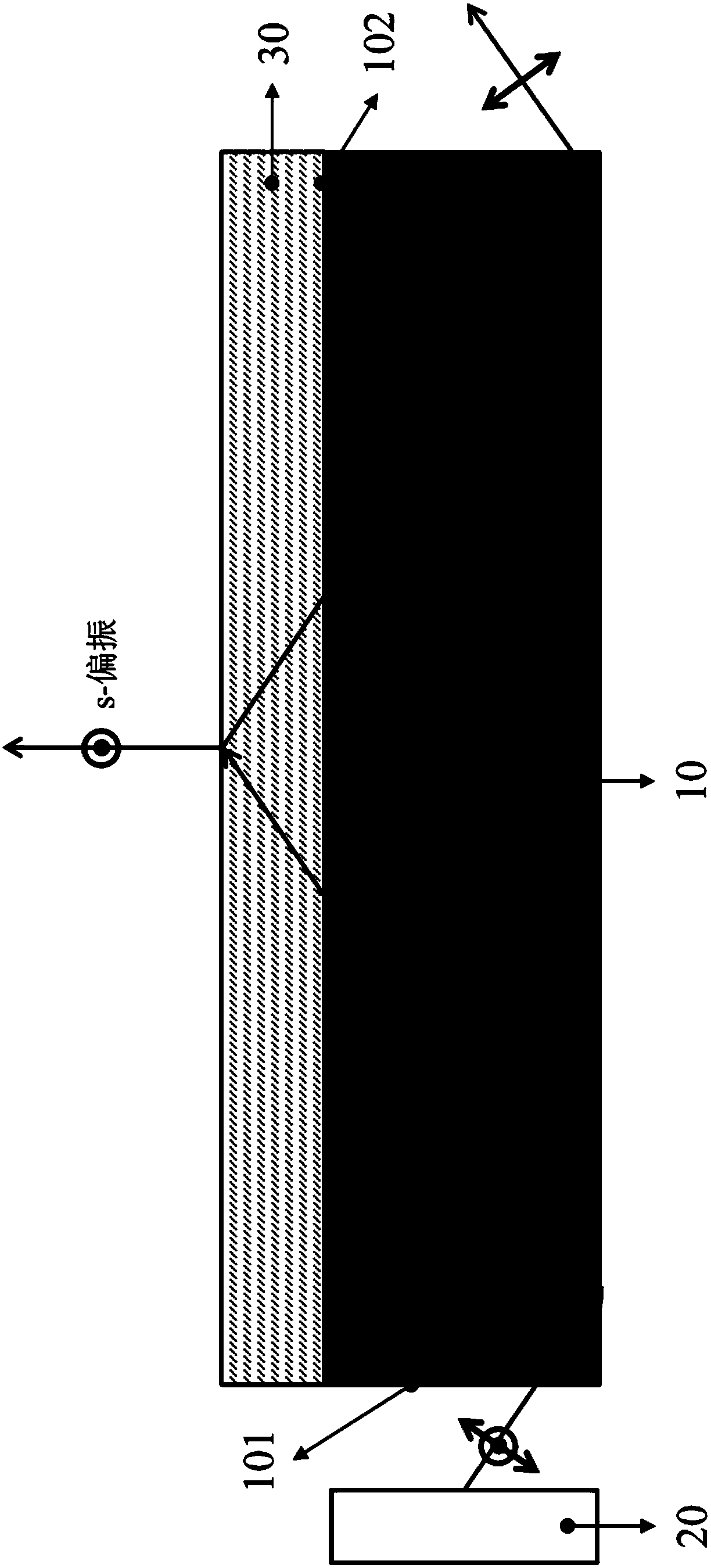

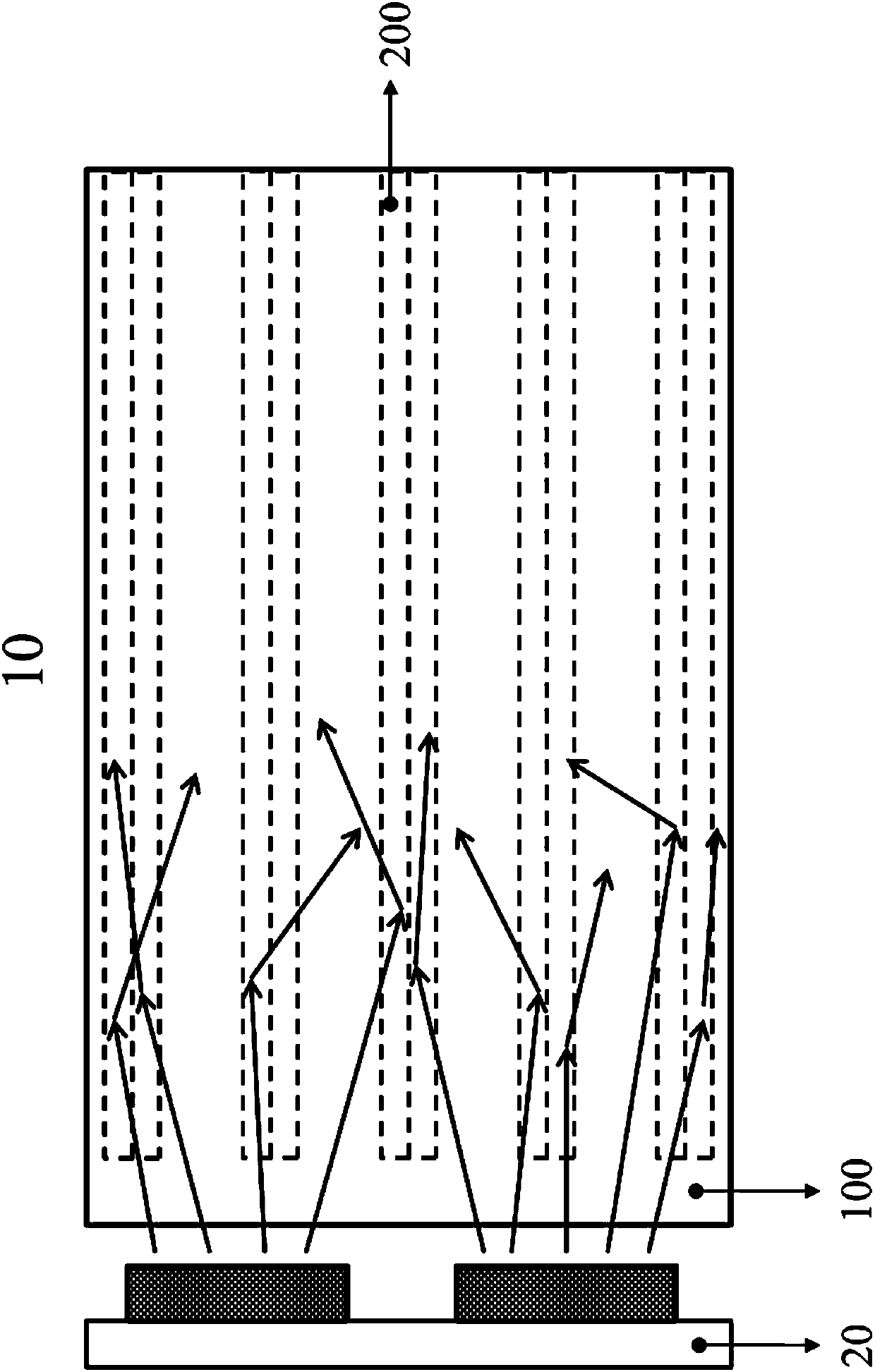

[0026] First refer to figure 1 , which shows a light guide plate 10 according to an embodiment of the present invention, which can be used for a polarized backlight. The light guide plate 10 includes a light incident surface 101, a light exit surface 102, a first surface 103, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap