Disinfection device for food processing workshop

A disinfection device and food processing technology, applied in disinfection, water supply equipment, construction, etc., can solve the problems of time-consuming, etc., and achieve high disinfection efficiency, good effect, and uniform preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is further described in detail through specific implementation methods:

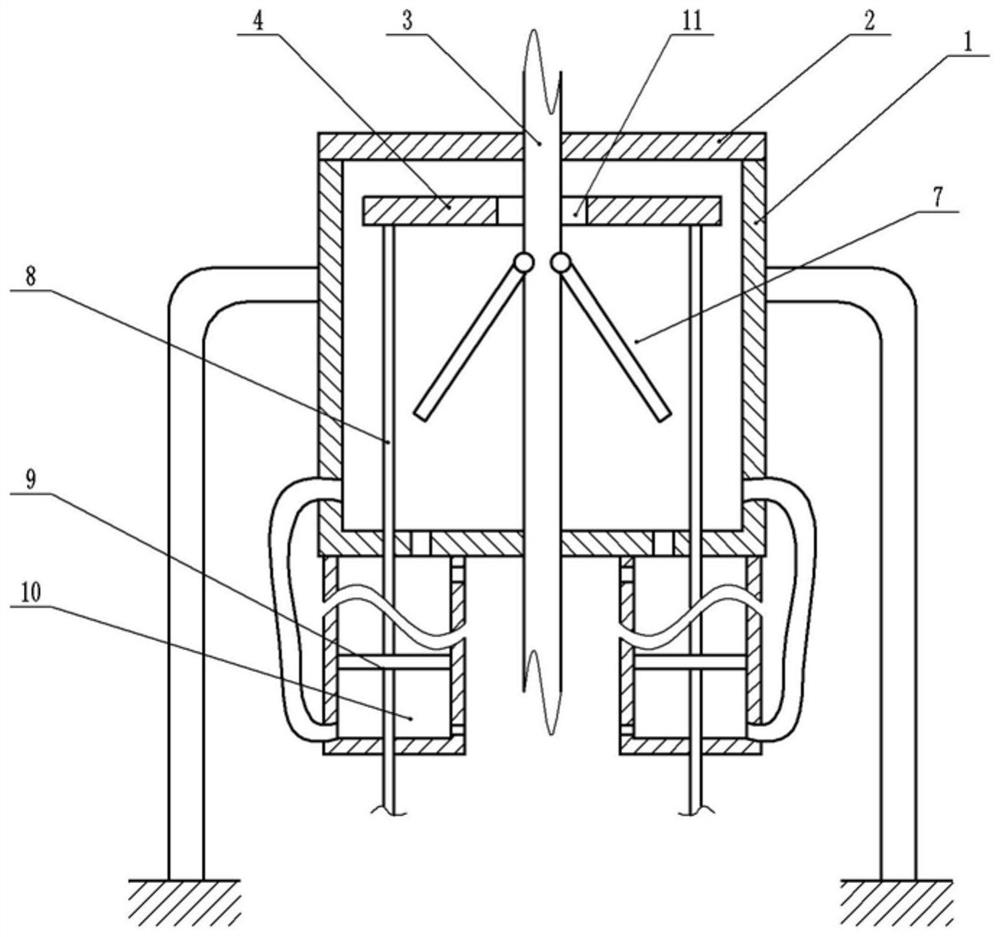

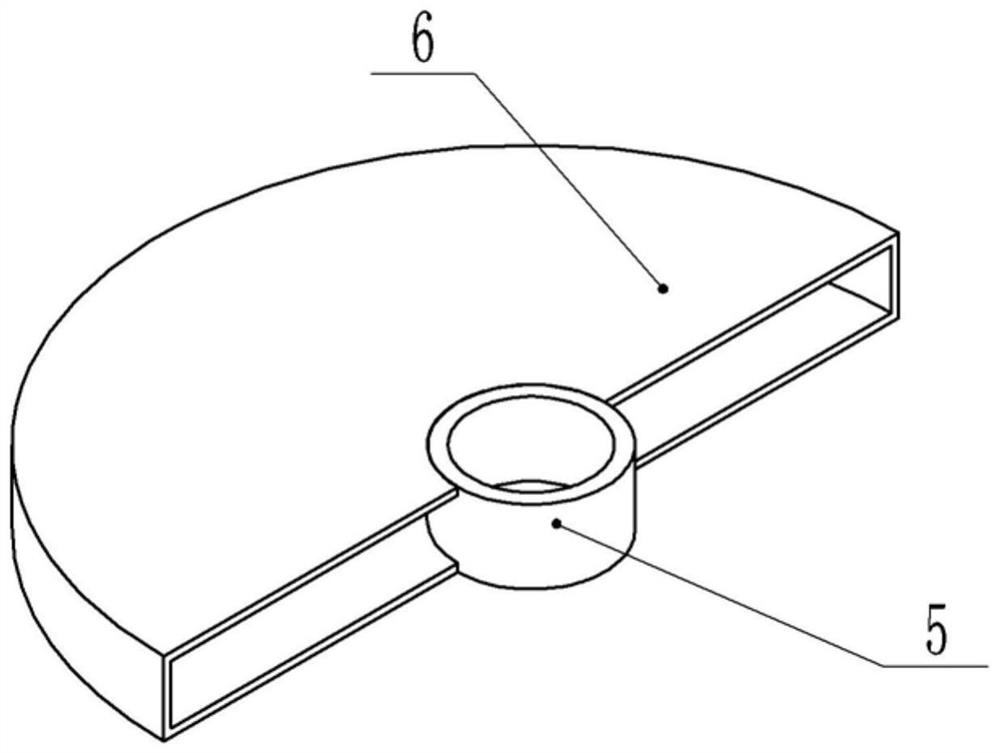

[0030] The reference signs in the drawings of the description include: preparation barrel 1, top cover 2, stirring shaft 3, slide plate 4, annular sleeve 5, half sleeve 6, stirring blade 7, piston rod 8, piston 9, piston barrel 10, through hole 11.

[0031] The embodiment is basically as attached figure 1 Shown: a disinfection device for a food processing workshop, including a preparation barrel 1 for preparing disinfectant and a number of spray pipes installed on the roof of the workshop. The lower ends of the spray pipes are connected with a number of nozzles.

[0032] The outer wall cover of the preparation barrel 1 is provided with a shading cloth, and during the preparation process, light is avoided and the volatilization of the disinfectant solution is reduced. The top cover 2 is detachably connected to the preparation barrel 1. Specifically, the top cover 2 includes two semi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com