Slide rail and battery pack assembly

A technology of battery packs and slide rails, which is applied to battery pack parts, electrical components, circuits, etc., can solve the problem of unstable positioning of battery packs, and achieve the effect of stable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

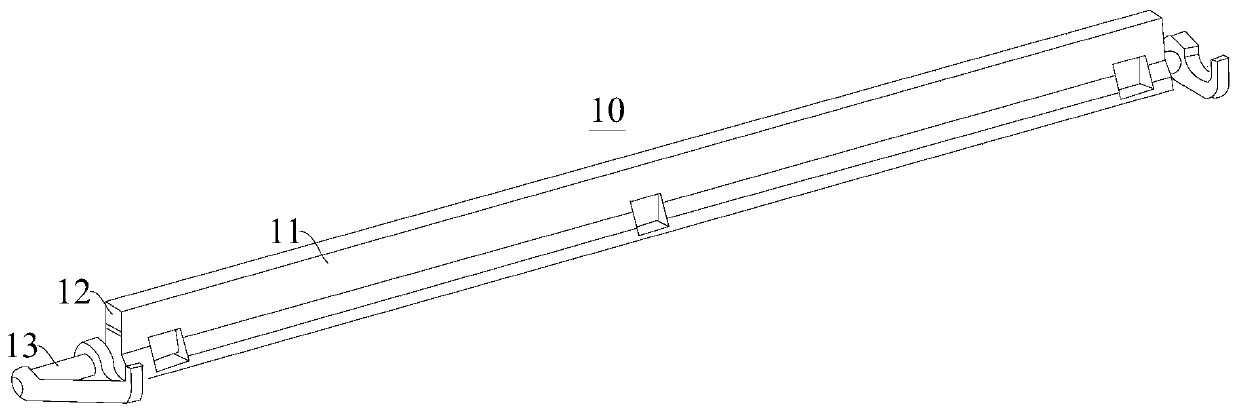

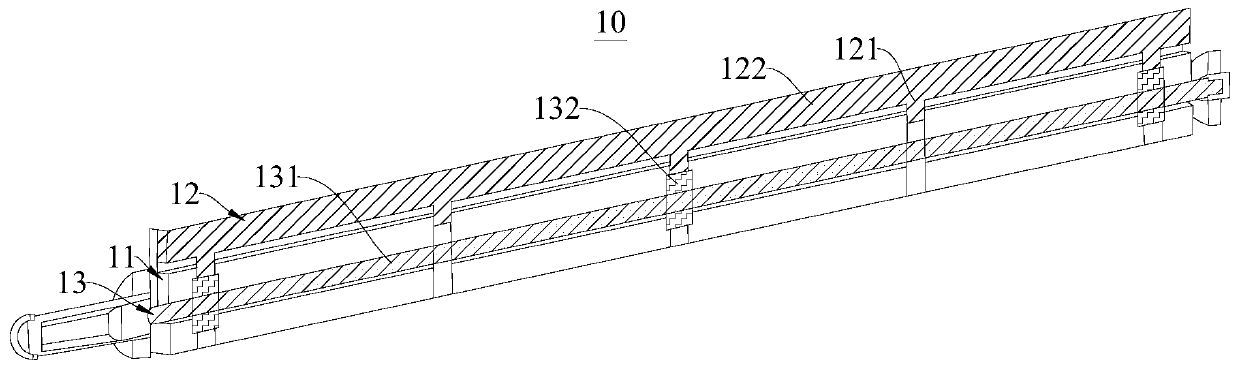

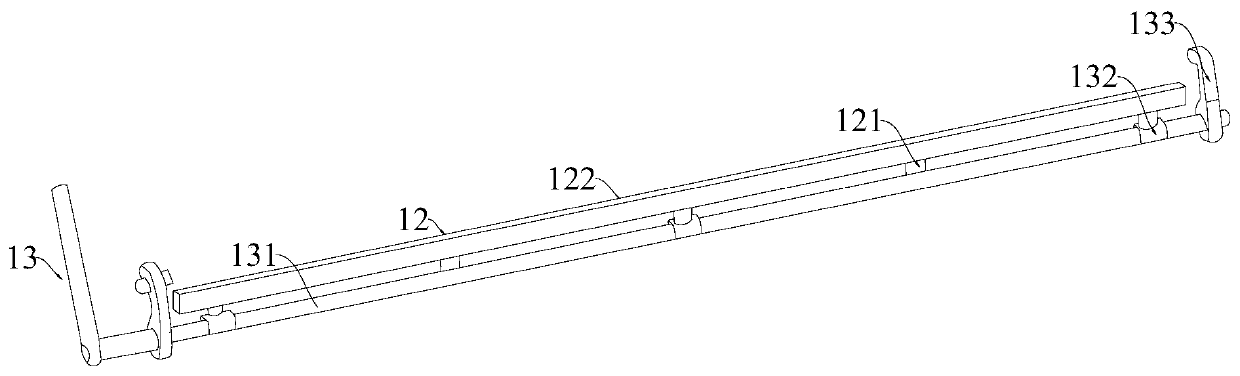

[0032] Please refer to figure 1 , the slide rail 10 is used to cooperate with the rollers of the battery pack 20, the slide rail 10 includes a fixed part 11, a movable part 12 and a transmission part 13, the movable part 12 and the transmission part 13 are all arranged on the fixed part 11, the transmission part 13 Can rotate under the action of external force, and further drive the movable part 12 to move relative to the fixed part 11, so that the movable part 12 is separated or contacted with the roller; when the movable part 12 and the roller are in contact, the roller of the battery pack 20 can pass on the slide Slide on the movable part 12 of the slide rail 10, so that the battery pack 20 is installed on the slide rail 10; when the movable part 12 is separated from the roller, the roller of the battery pack 20 cannot slide on the movable part 12 of the slide rail 10, so that it will not be in contact with the slide rail 10. The rail 10 moves relatively, so that the batter...

no. 2 example

[0044] Please continue to refer to Figure 4 , the battery pack assembly 100 includes a battery pack 20 and two slide rails 10, the battery pack 20 is in the shape of a cuboid, the battery pack 20 has a first side and a second side oppositely arranged, and the first side and the second side are provided with The roller frame 21 and the slide rail 10 that cooperate with each other.

[0045] There are many ways to install the battery pack 20 on the electric vehicle. In this embodiment, the electric vehicle is provided with an installation cavity, and two slide rails 10 are arranged at intervals in the installation cavity, which are connected to the two sides of the battery pack 20 respectively. The rollers in the roller frame 21 cooperate. In other embodiments, the two slide rails 10 are respectively fixedly connected to both sides of the battery pack 20 to jointly form the battery pack assembly 100, and the two slide rails 10 on both sides of the battery pack assembly 100 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com