Heavy haul train cycle braking method and system based on double air braking pipes

A technology for air braking and heavy-duty trains, which is applied in the direction of pneumatic brakes, brakes, hydrostatic brakes, etc., and can solve problems such as limited application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

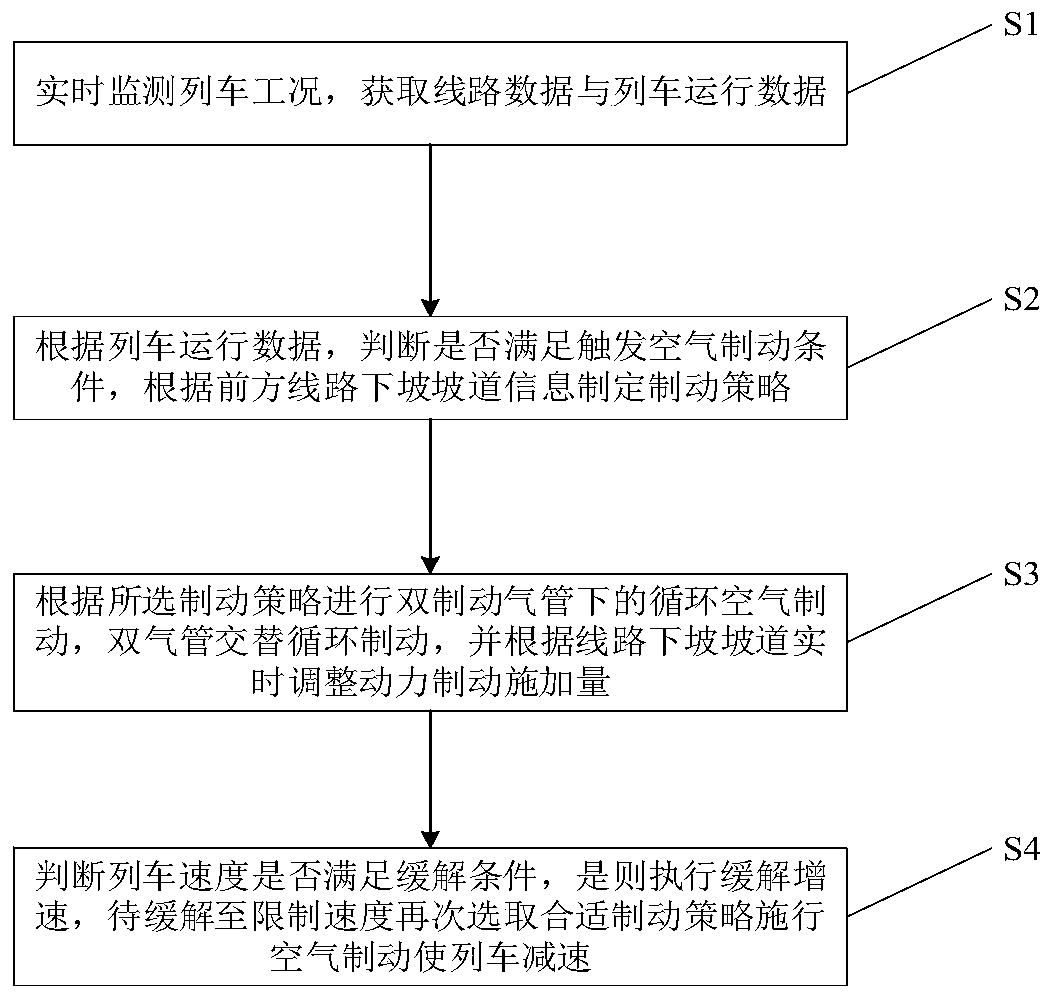

[0051] Such as figure 1 As shown, on the one hand, the present invention discloses a heavy-duty train cycle braking method based on double brake air pipes, the method comprising:

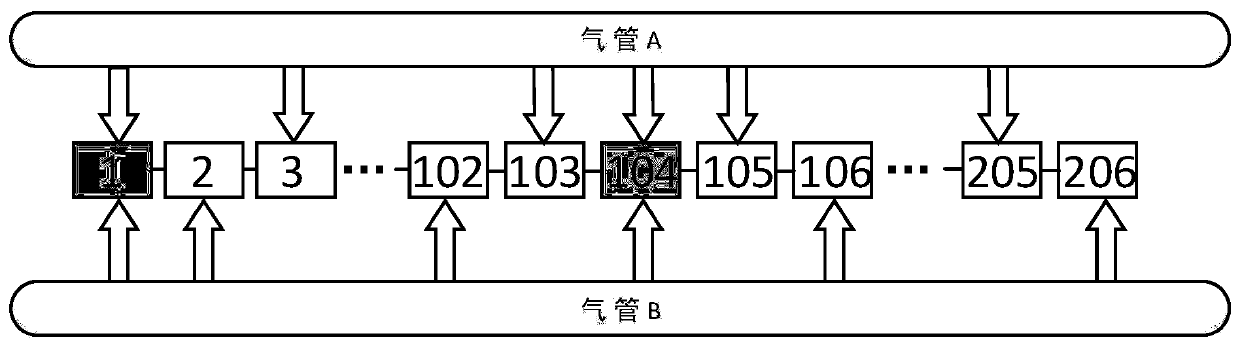

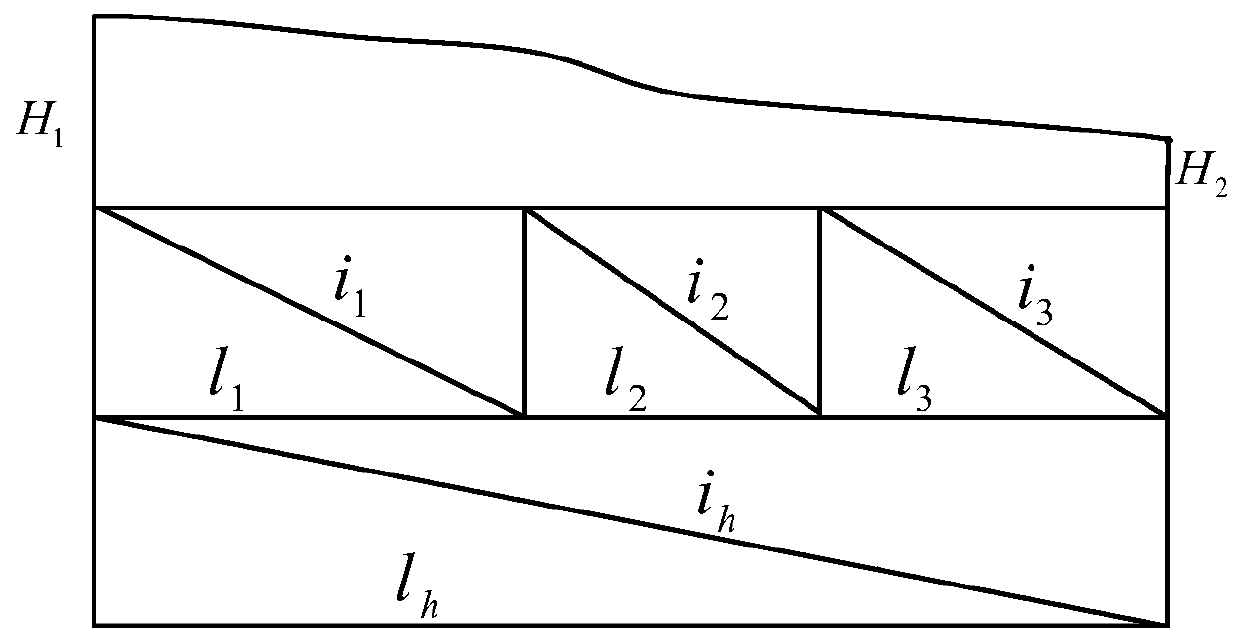

[0052] S1: Real-time monitoring of train working conditions, acquisition of line data and train operation data; the dual air brake tubes use two air brake tubes to control the air brakes of half of the vehicles respectively, and adjacent vehicles are controlled by different air brake tubes control; such as figure 2 As shown, the train marsha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com