Folding arm power cable electric operation forklift

A technology of power cables and folding arms, applied in the direction of hoisting devices, etc., can solve the problems of low construction efficiency, lack of brake and braking devices, and reduced mass, and achieve the effects of greatly reducing self-weight and cost, saving human resources, and simplifying structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

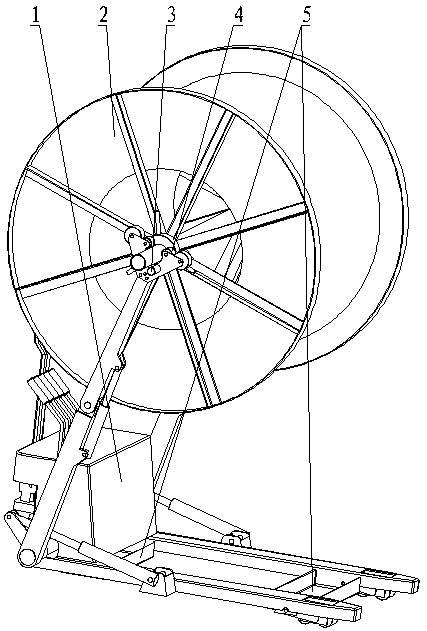

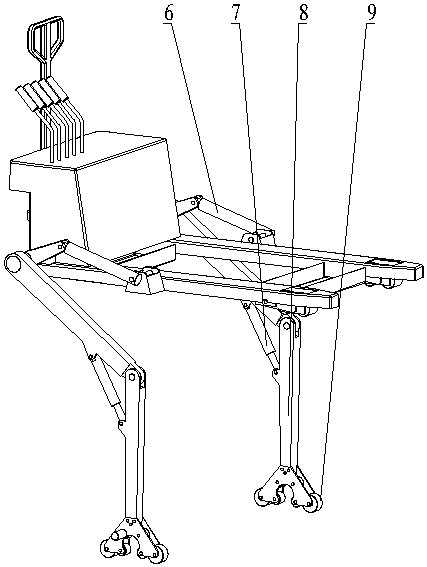

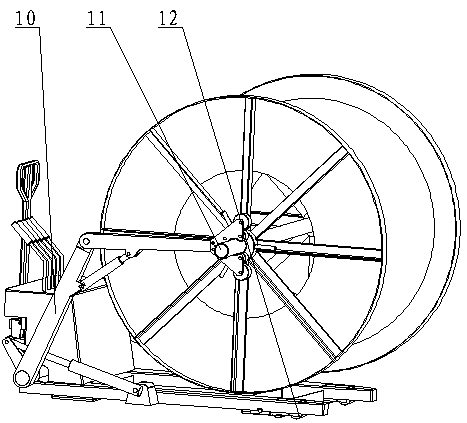

[0028] As shown in the figure, the two ends of the electric forklift 1 are provided with a right folding arm assembly 8, a left folding arm assembly 10, and folding arms are arranged between the right folding arm assembly 8, the left folding arm assembly 10 and the electric forklift 1. The arm lifting device 6 drives the right folding arm assembly 8 and the left folding arm assembly 10 to rotate upwards, horizontally and downwards.

[0029] Right folding arm assembly 8, left folding arm assembly 10 all establish front and rear arm lifting device 7 between their rear arm and forearm, drive folding action between rear arm and forearm; Forearm end all establishes roller 9, block pulley 4, The arrangement of the roller 9 is convenient for the forklift to get on or off the car by itself; the shaft rod 11 passes through the shaft hole of the cable reel 2 and is arranged in the pulley block (4) of the right folding arm assembly 8 and the left folding arm assembly 10, The pulley block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com