Telescopic boom cable manual operation forklift

A telescopic arm, forklift technology, applied in the direction of lifting device, etc., can solve the problems of lack of brake and braking device, low efficiency, faster extraction speed, etc., and achieve the effect of saving human resources and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

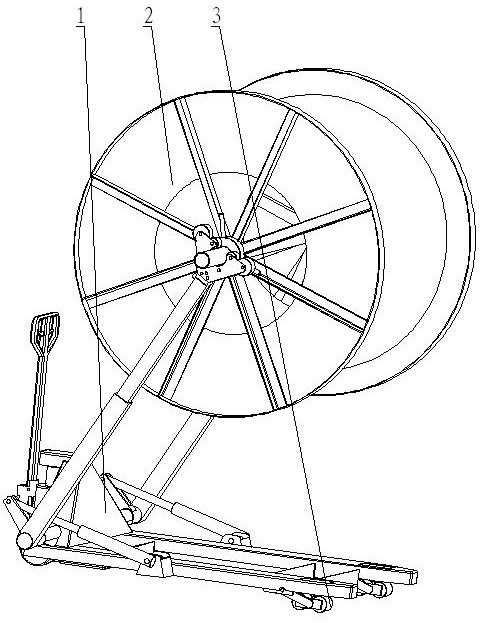

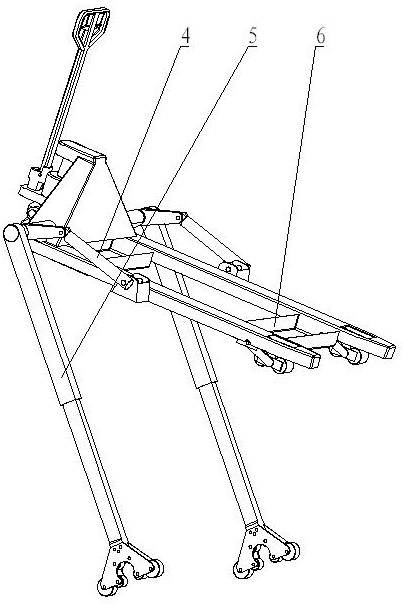

[0026] As shown in the figure, the two ends of the manual forklift 1 are equipped with a left (right) telescopic arm assembly 5, and a telescopic arm assembly lifting device 4 is provided between the left (right) telescopic arm assembly 5 and the manual forklift 1. Drive the left (right) telescopic arm assembly 5 to perform upward, horizontal and downward rotation actions.

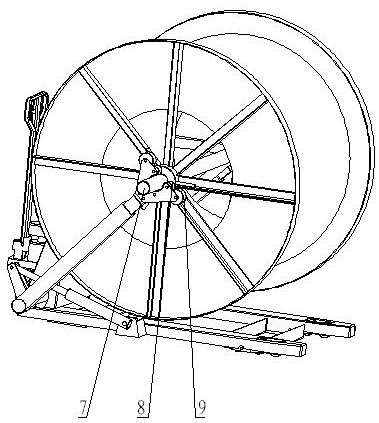

[0027] A telescopic device is set between the rear arm and the forearm in the left (right) telescopic arm assembly 5, so that the forearm moves along the set track, and the forearm moves telescopically under the drive of the power device; roller 9 and pulley block 8 are arranged at the end of the forearm , the setting of roller 9 is convenient for the voluntary boarding or getting off of this forklift;

[0028] The lower part of the manual forklift 1 is provided with a shelving device 6. When the manual forklift 1 is lowered and the front and rear moving wheels 3 are all retracted, the shelving device 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com