Method for non-vibration dismantling of concrete building structure

A technology for concrete construction and manual hoist, applied in building construction, construction, building maintenance and other directions, can solve problems such as cracks, large vibration, structural deformation, etc., to achieve the effect of reducing dust content, small impact and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

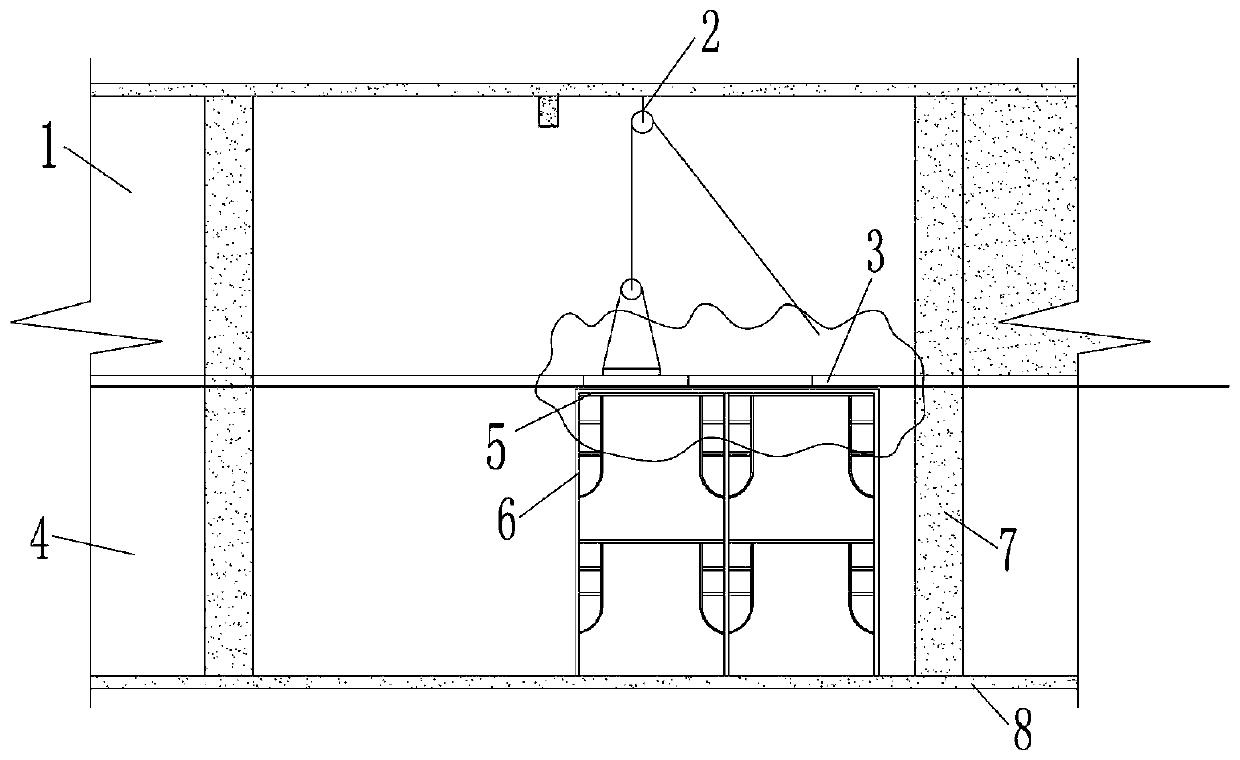

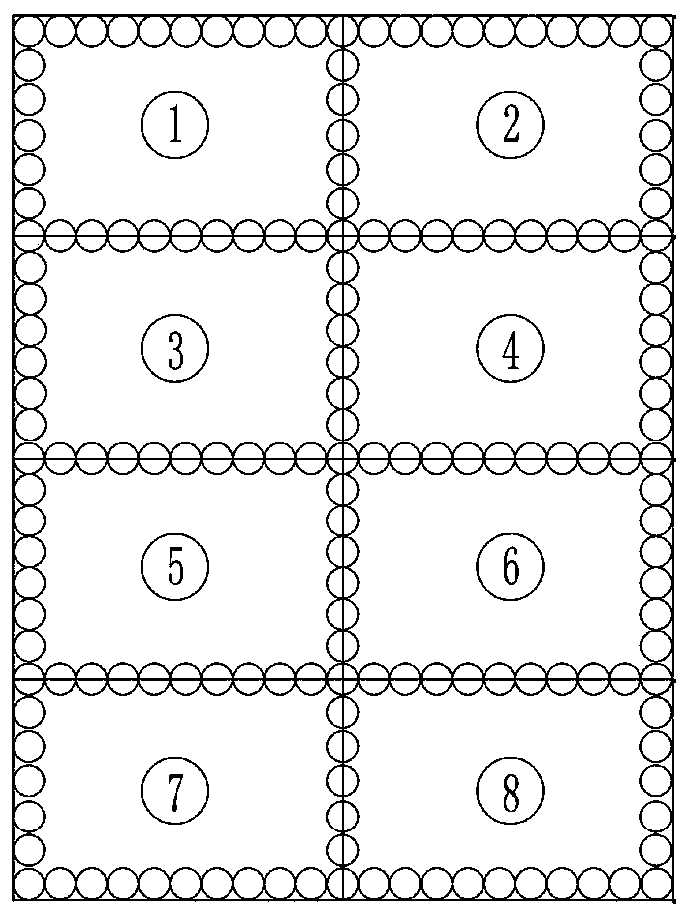

[0044] Such as figure 1 As shown, this embodiment takes the demolition of the floor slab of a five-story machine room of a certain TV transmitting station as an example to carry out drilling and cutting, and the demolition construction steps are:

[0045] Site preparation:

[0046] (1) First of all, familiarize yourself with the general situation of the demolished floor and the surrounding environment, and find out the structure, construction, water, electricity, equipment and pipelines of the building, and the hidden facilities. The person in charge of demolition shall make a detailed disclosure to the staff participating in the demolition according to the construction organization design and safety technical regulations, and do a good job in corresponding safety education.

[0047] (2) Then clean up the construction site, remove the materials and equipment within the scope of demolition, and make corresponding enclosures;

[0048] (3) Mechanical equipment preparation

[...

Embodiment 2

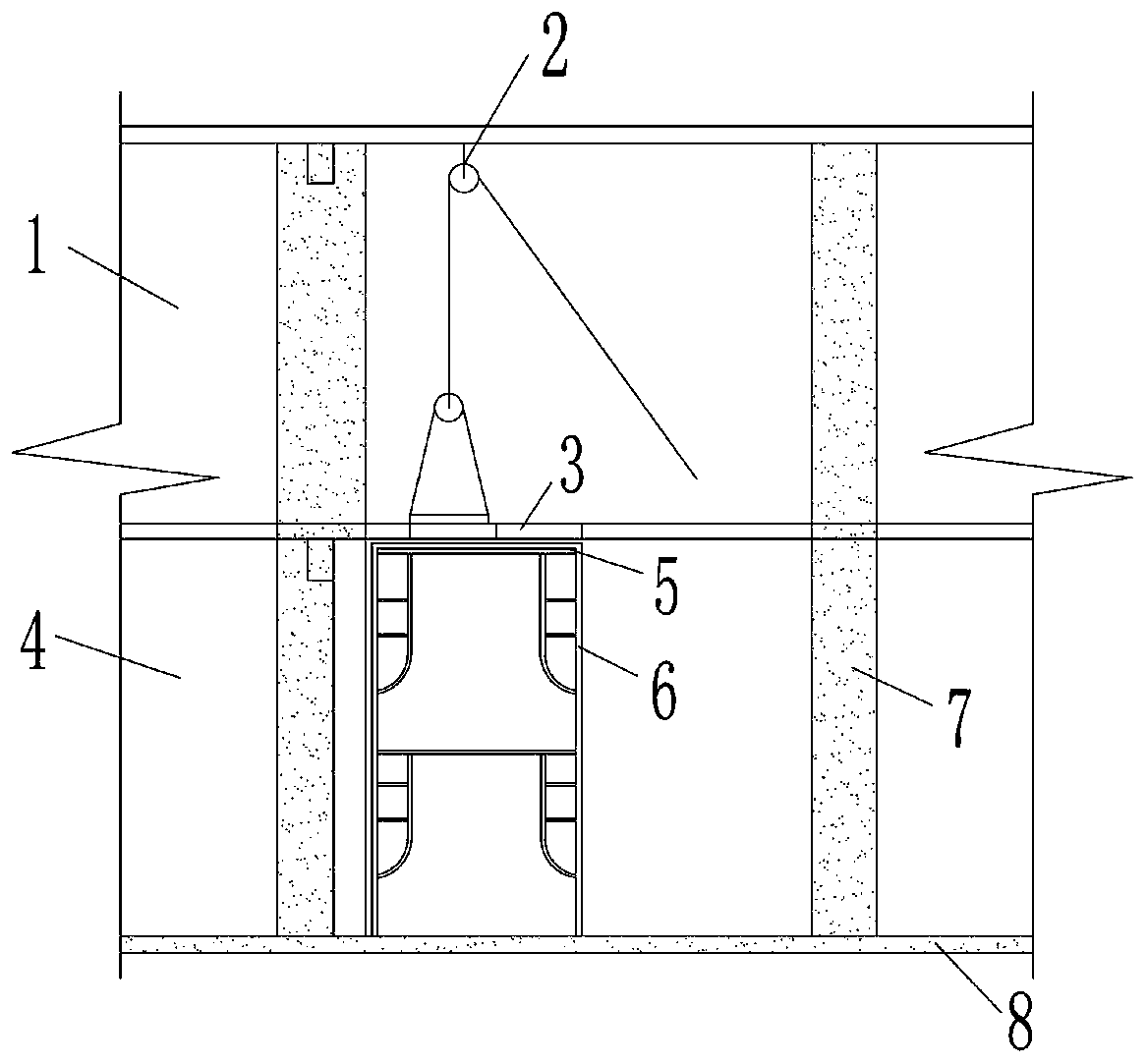

[0064] In this embodiment, the third and fourth floors of a medical center need to install a vegetable delivery ladder to cut the floor as an example to carry out drilling and cutting. The demolition and construction steps are as follows:

[0065] Site preparation:

[0066] (1) First of all, familiarize yourself with the general situation of the demolished floor and the surrounding environment, and find out the structure, construction, water, electricity, equipment and pipelines of the building, and the hidden facilities. The person in charge of demolition shall make a detailed disclosure to the staff participating in the demolition according to the construction organization design and safety technical regulations, and do a good job in corresponding safety education.

[0067] (2) Then clean up the construction site, remove the materials and equipment within the scope of demolition, and make corresponding enclosures;

[0068] (3) Mechanical equipment preparation

[0069] Acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com