Construction method of piles and drill pipe system special for piles

A construction method and drill pipe technology, which is applied in the direction of drill pipe, earth square drilling, drill bit, etc., can solve the problem that the mixing technology in the hard soil area cannot be stirred, the down-the-hole hammer technology in the soft soil area cannot be flushed, and the cement-soil composite pile technology is affected. Development and other issues to achieve the effect of improving timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A pile construction method is characterized in that: comprising the following steps:

[0030] (1) Construction of the first pile:

[0031] (1) Move the machine into place: move the drill pipe system to the set pile position;

[0032] (2) Spinning sinking: Spinning and sinking the drill pipe system to the set depth;

[0033] (3) Rotary pull up: lift the drill pipe system up to the set height;

[0034] (4) Repeat steps (2) and (3) until the first pile meets the set requirements;

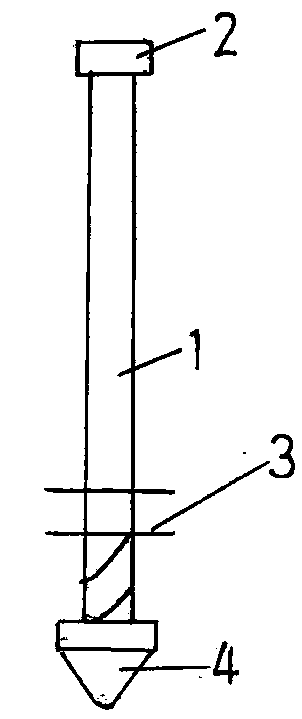

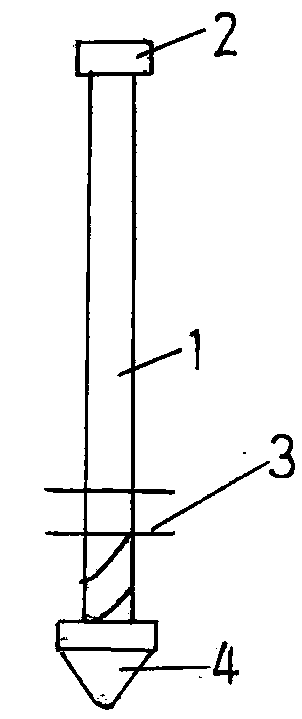

[0035] The drill pipe system in step (1) includes: the drill pipe is a smooth or helical blade steel pipe, with at least one of the passages for air injection, water spray, slurry spray, and ash spray, and the upper part of the drill pipe is equipped with a power head with adjustable power. The lower part of the rod is equipped with a horizontal mixing blade, and the lower part of the drill rod is equipped with a submersible hammer for mechanical or hydraulic reaming to form a drill rod syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com