Method and device for detecting distributed contact resistance pressure of tulip contact

A plum-blossom contact and contact resistance technology, applied in the direction of measuring devices, force/torque/work measuring instruments, force measurement, etc., can solve problems such as the inability to realize the distributed measurement of the contact pressure of the plum-blossom contact, so as to ensure the current carrying capacity and The effect of safe operation and improvement of work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

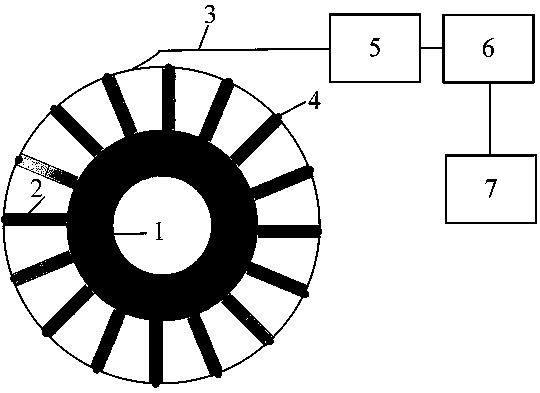

[0025] refer to figure 1

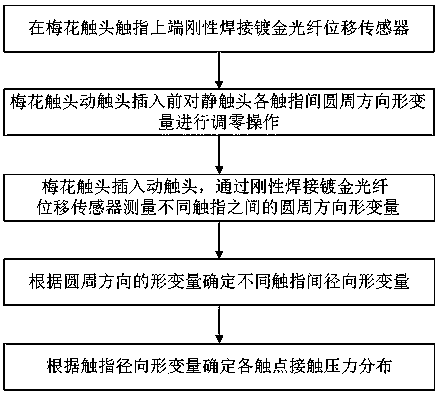

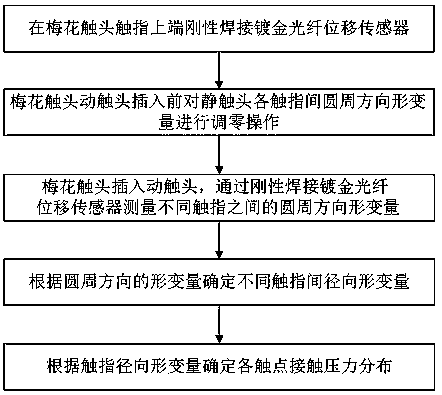

[0026] A method for detecting distributed contact resistance pressure of plum blossom contacts, comprising the following steps:

[0027] (1) Rigidly weld the gold-plated optical fiber displacement sensor on the upper end of the plum-blossom contact finger, specifically: mark the solder joints on each finger of the plum-blossom contact static contact in the free state (the moving contact of the plum-blossom contact has not been inserted), and weld The position of the point is located in the middle of the thickness direction of the outer surface of each contact finger. The slender body of the optical fiber displacement sensor corresponding to the solder joint position of the plum blosso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com