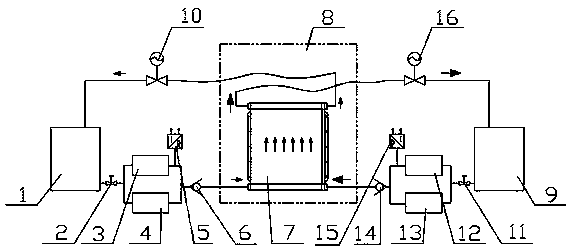

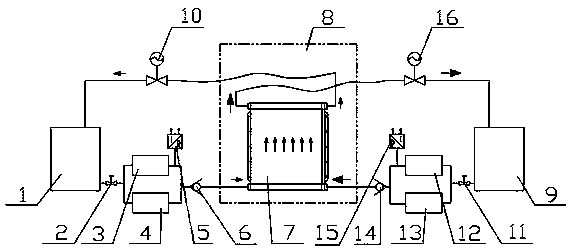

Operating life test system for wind power heat dissipation plate piece under extreme conditions

A heat dissipation plate and extreme condition technology, which is applied in the field of working life test system, can solve problems such as lack of samples in the test system, failure to verify the working life of wind power heat dissipation plate, single pressure pulse or withstand voltage test, etc., to improve product quality effect on reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Before operation: Fill the low-temperature water tank 1 with an aqueous solution of ethylene glycol at a temperature of -5°C and the high-temperature water tank 9 with an aqueous solution of ethylene glycol with a temperature of 95°C, and put the cooling plate 7 at a temperature of -50°C~ + In the 80°C high and low temperature box 8, the temperature of the ethylene glycol aqueous solution is detected at the same time, and the temperature is automatically adjusted to reach the set value, and then the pressure value of the high-pressure pump 3 and high-pressure pump I12 is adjusted to 2.5~3MPa, and the operation is set separately The time is 3 minutes; then adjust the pressure value of delivery pump 4 and delivery pump I13 to 0.3~0.5MPa, and set the running time to 5 minutes respectively.

[0028] Start of operation: first open the ball valve 2 and the electric ball valve 10, so that the ethylene glycol aqueous solution with a temperature of -5°C in the low-temperature wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com