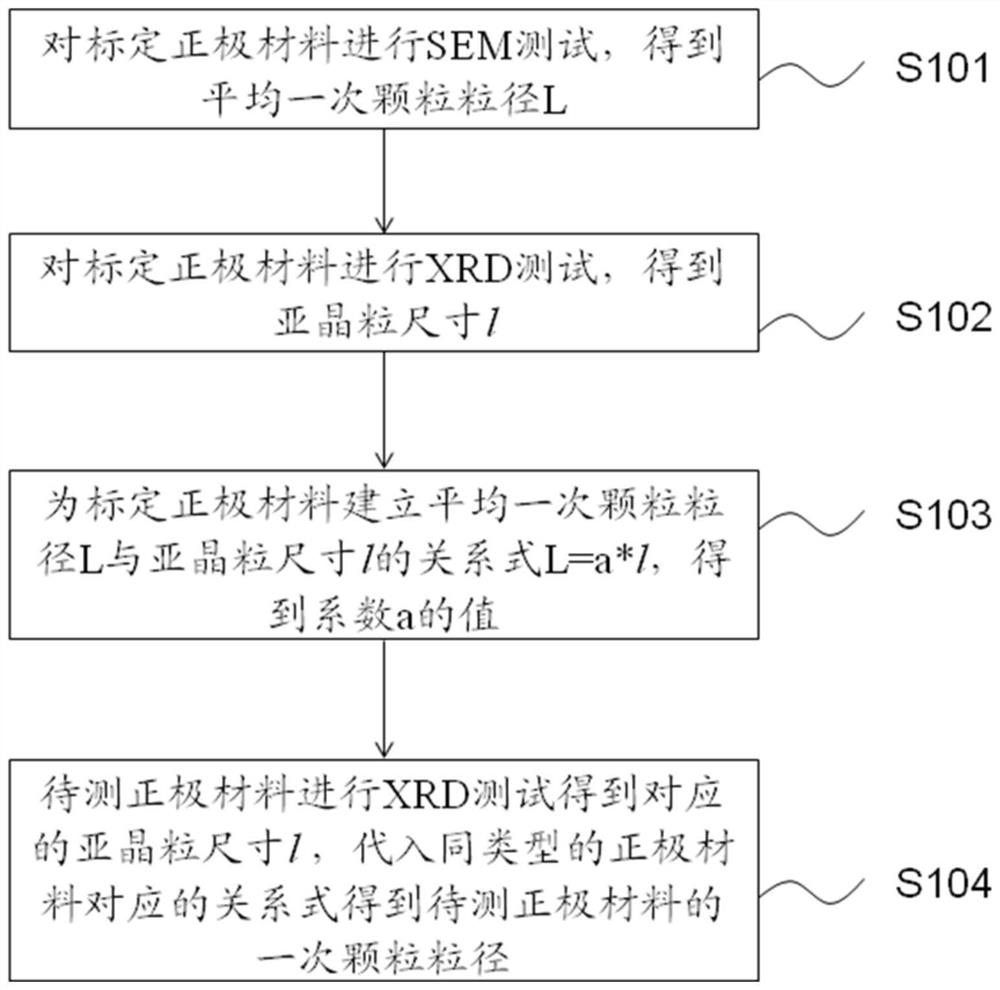

Method for measuring particle size of primary particles of positive electrode material

A cathode material, particle size technology, applied in the analysis of materials, particle and sedimentation analysis, material analysis using wave/particle radiation, etc., can solve the problem that the primary particle size is not representative, the test efficiency is low, and the test process is complicated and other problems to achieve the effect of efficient and fast testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

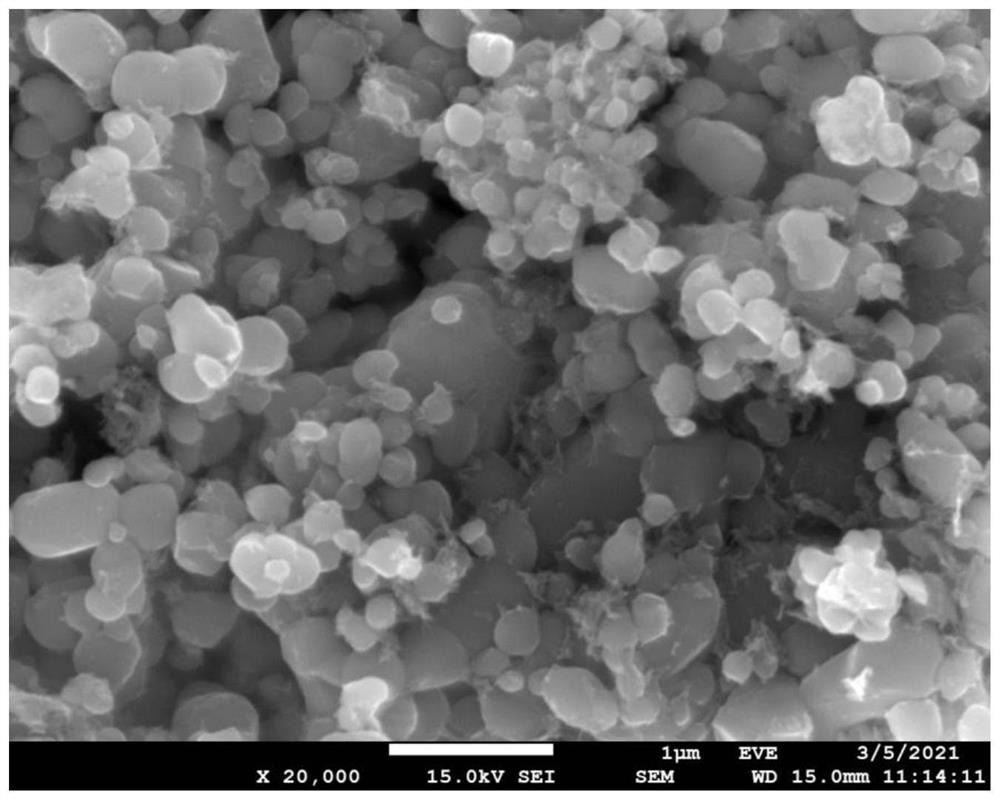

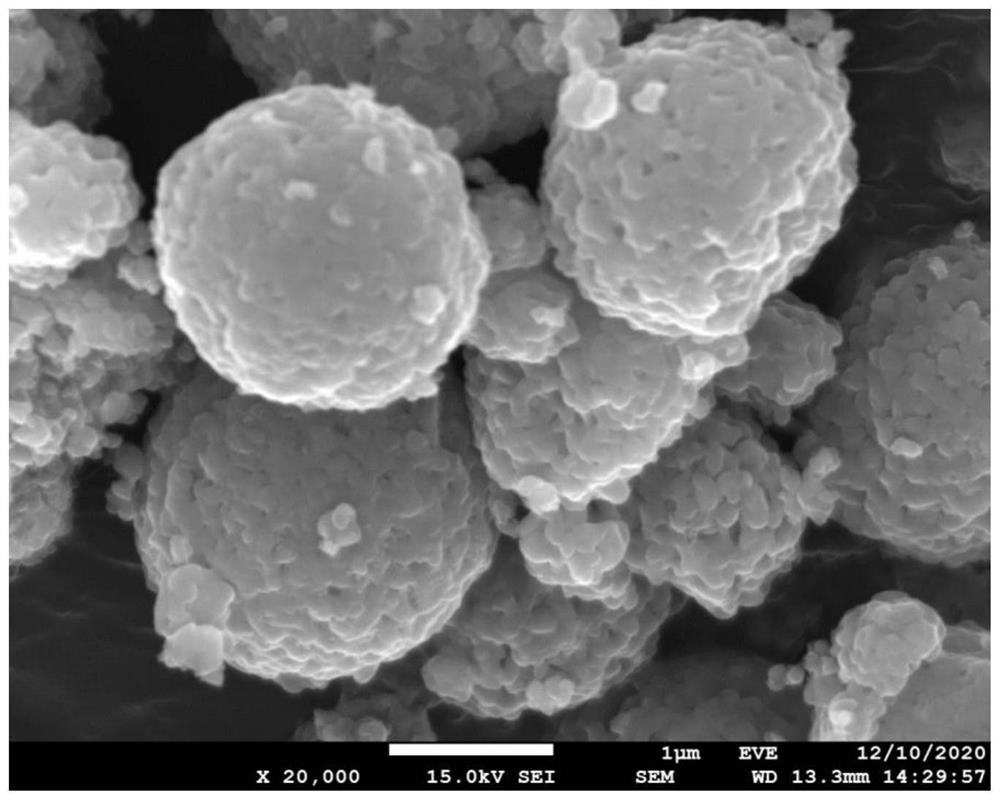

[0034] Preparation of positive electrode material samples before SEM test: stick a double-sided conductive tape on the loading tray, take a small amount of positive electrode material samples on the tape near the center of the loading tray, and use the ear cleaning ball to radially outward toward the loading tray Blow lightly in the direction so that the sample powder can be evenly distributed on the tape, and at the same time blow off the powder that is not firmly bonded. Apply conductive silver paste to the edge of the tape to connect the sample to the loading plate. After the silver paste dries, steam gold deal with.

[0035] S102: Carry out XRD test to anode material, obtain subgrain size l;

[0036] Carry out XRD test and analysis on the selected cathode material samples. The XRD scanning range 2θ is 10-80°, the scanning speed is ≤2° / min, and the step size is 0.01-0.02°. The obtained XRD pattern is refined on the JADE software, and passed The XRD spectrum after refinemen...

Embodiment 1

[0050] Test the primary particle size of a lithium iron phosphate: Weigh the sample to prepare a sample, and perform an XRD test on a Bruker X-ray diffractometer of the model D2PHASER. The scanning range 2θ is 10-80°, and the scanning speed is 2 ° / min, step length 0.02°, the obtained XRD spectrum was processed on the JADE software to obtain a refined XRD spectrum, using the half maximum width β of the strongest diffraction peak (2θ between 30°-40°), the data Read out by the equipment software, β=0.00953, θ=17.875°, and substitute it into the Scherrer formula l=Kλ / (βcosθ), K is the shape factor, take K=1, λ is the incident wavelength of X-rays, and use the Cu target Kα line, λ=0.15418nm, obtain the corresponding sub-grain size l, l=17.4nm, step S103 obtains the relational formula of lithium iron phosphate as L=5.75l, and substitute it to obtain the L=100nm of the test sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com