A Multi-period Sliding Mode Repetitive Control Method for CNC Machine Tool Linear Motor Based on Disturbance Compensation

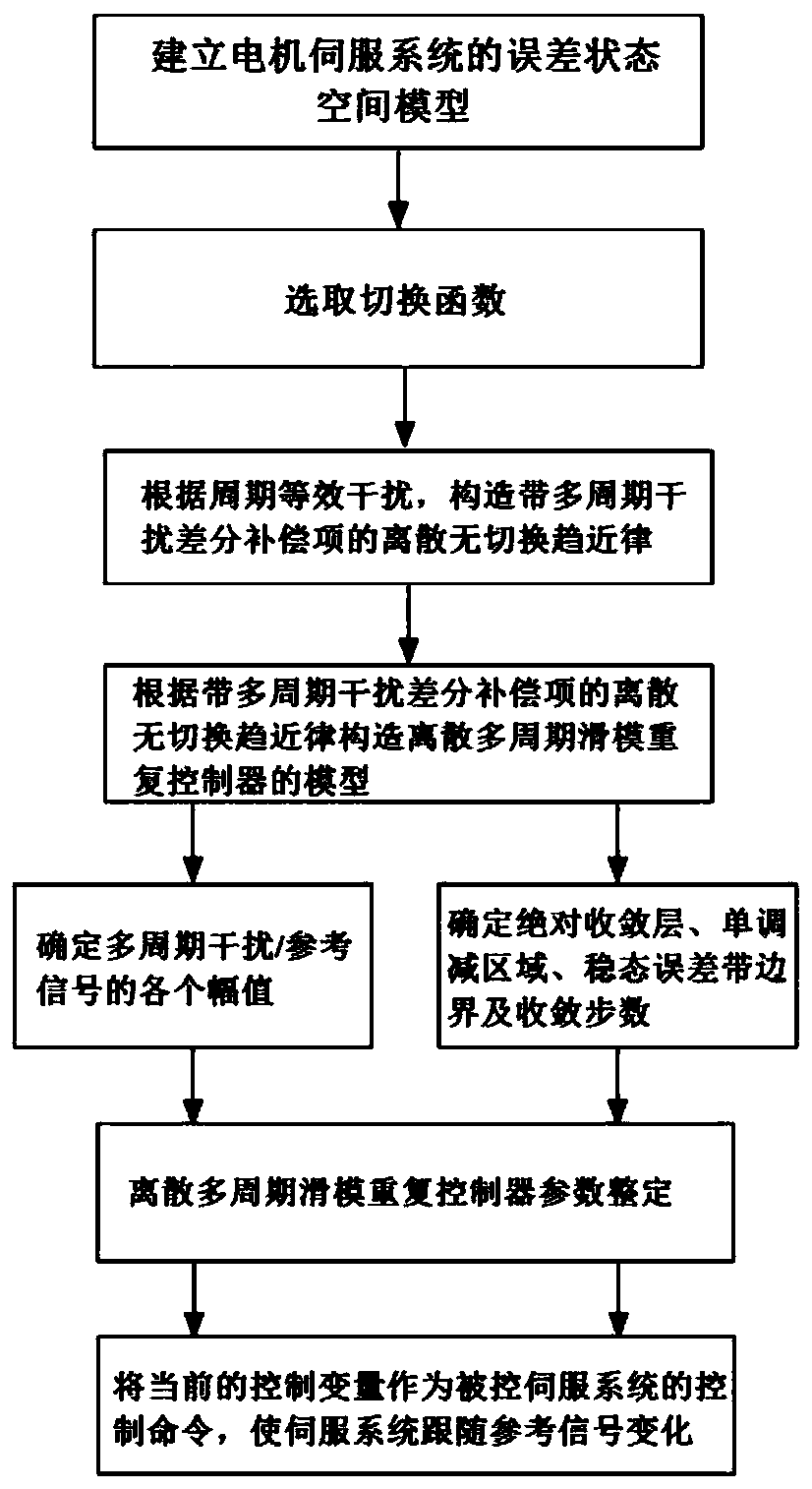

A technology of CNC machine tools and linear motors, which is applied in the directions of digital control, electrical program control, program control, etc., can solve the problems of limited use range, occupation, periodic interference, slow memory occupation, etc., and achieves the effect of a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

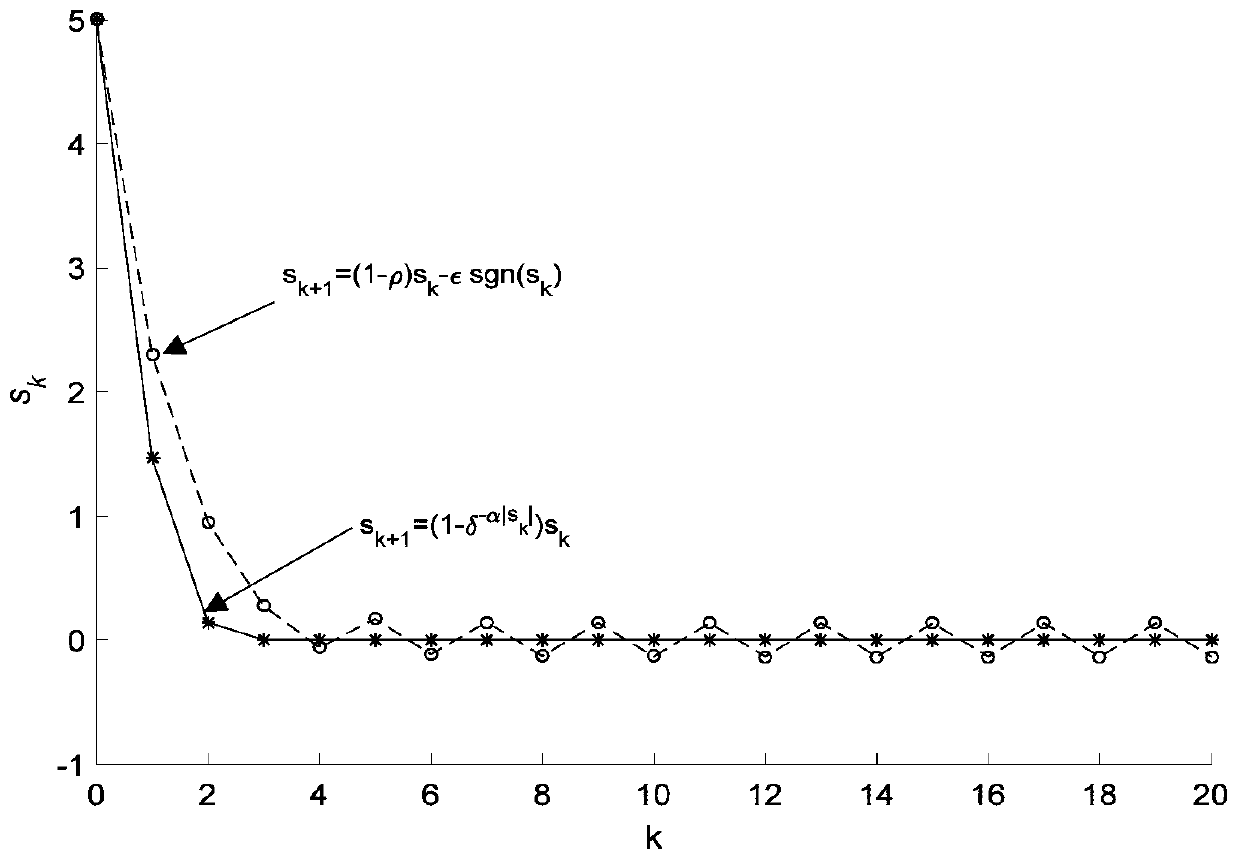

Method used

Image

Examples

Embodiment

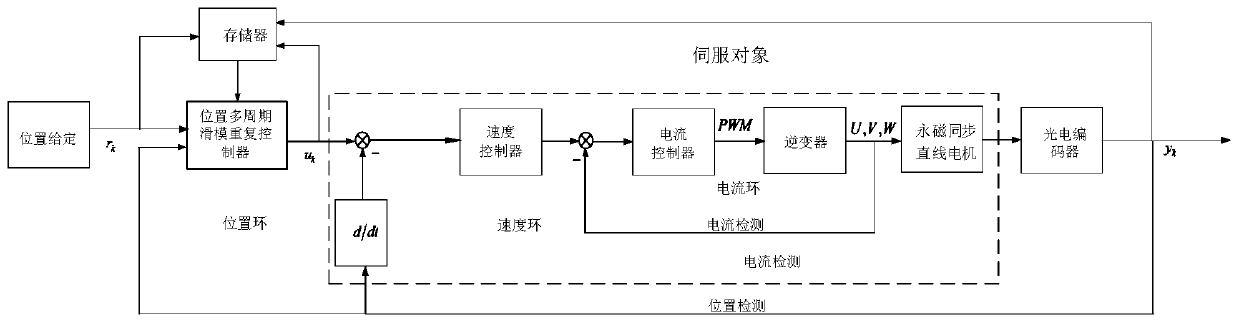

[0161] The permanent magnet synchronous motor servo system on the CNC machine tool undertakes repetitive tasks and needs to track the periodic reference trajectory. The reference trajectory is composed of multiple periodic signals and has periodic symmetry. The motor adopts three-loop control, in which the speed loop and current loop controllers are provided by the ELMO driver, and the PI algorithm is used for adjustment. The block diagram of the entire permanent magnet synchronous linear motor control system is shown in image 3 . The discrete multi-period sliding mode repetitive control method given by the present invention implements position loop control for the linear motor system, and its control strategy framework diagram can be found in Figure 4 . For a position reference signal with periodic symmetry, when the motor servo system enters the steady-state stage, the system disturbance will also exhibit the same periodic symmetry. Designing a position loop controller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com