Spice processing method and spice processing device

A processing method and technology of a processing device, which are applied in the field of spice processing methods and devices, can solve the problems of too small spice particles, too much stimulation, affecting the taste and taste, etc., and achieve high quality and overcome discomfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

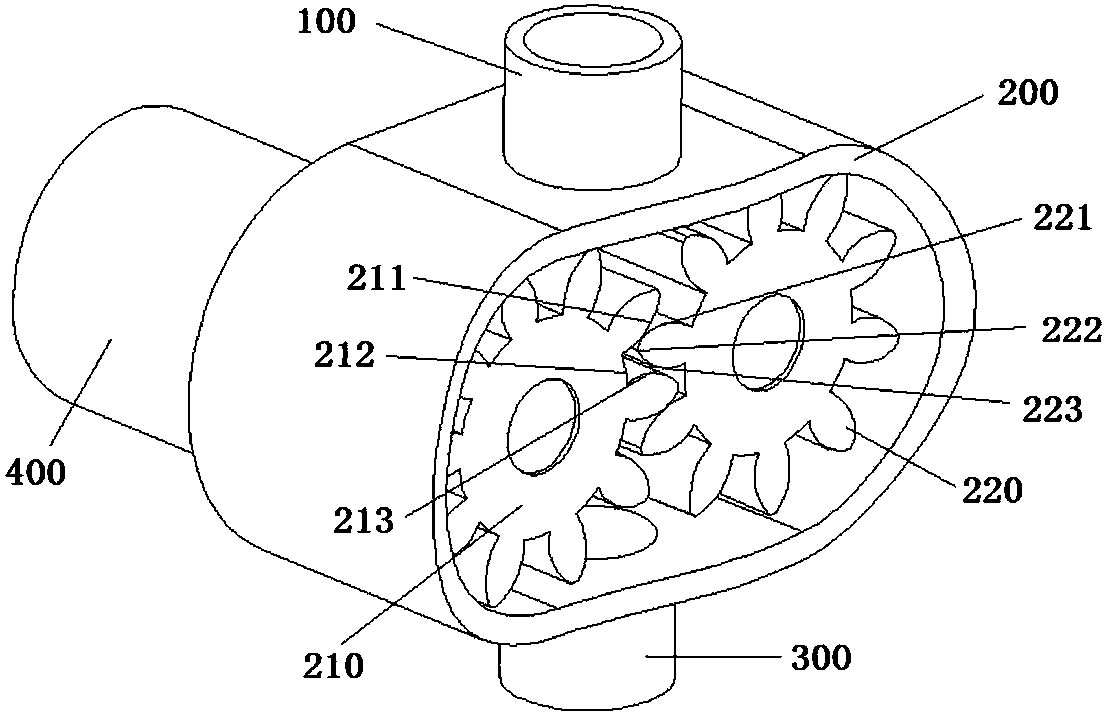

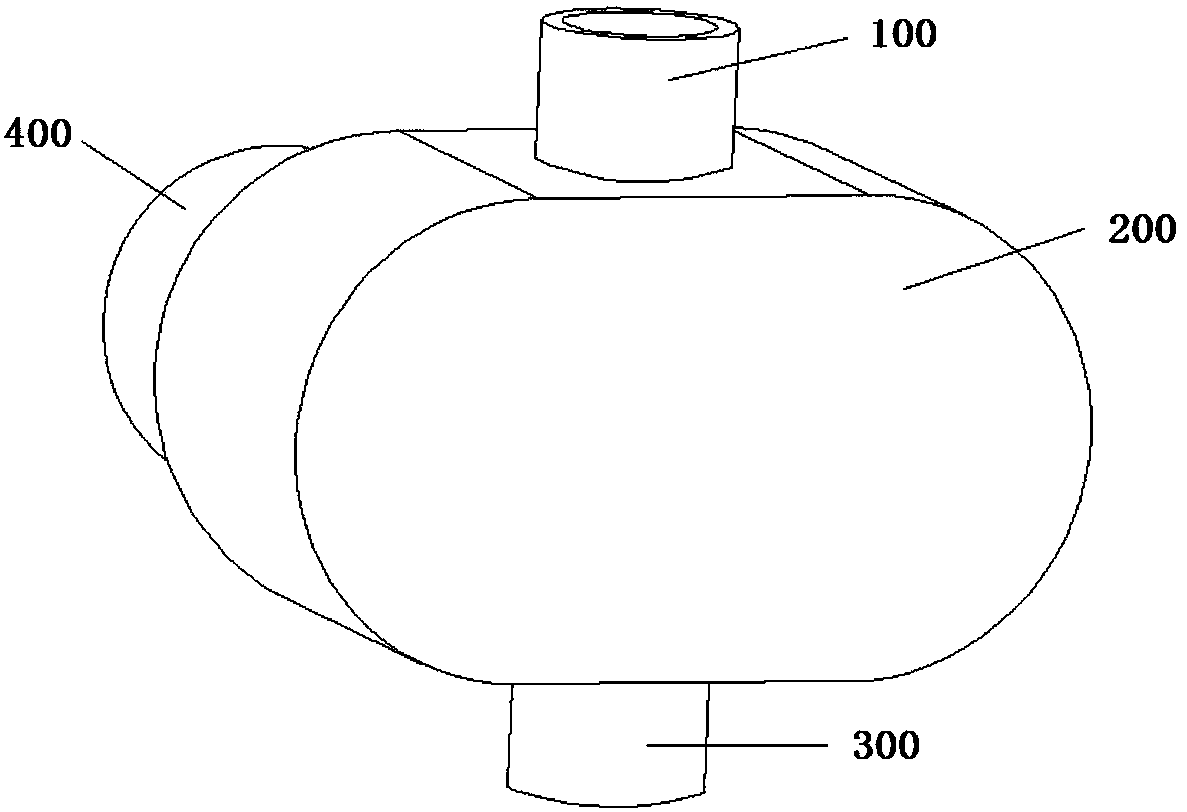

[0031] The spice processing device of this example, such as figure 1 , figure 2 and Figure 4 As shown, it includes a housing unit 100 , a housing 200 , a blanking unit 300 and a driving device 400 .

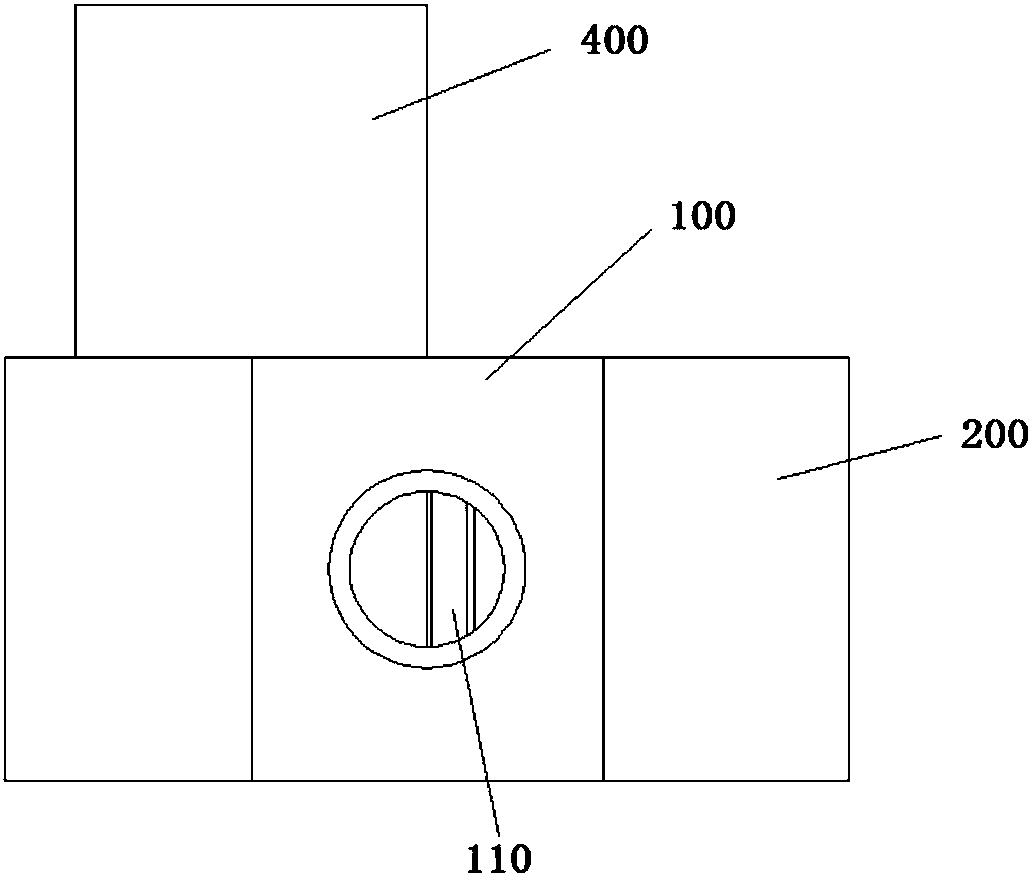

[0032] Such as figure 1 and figure 2 As shown, the container unit 100 is a hollow cylindrical structure, which is used to store spices to be pressed. Such as image 3 As shown, a valve 110 is provided in the container unit 100 , and the valve 110 is used to limit the feeding speed and amount of spices entering the pressing unit 200 .

[0033] In other embodiments, the containing structure 100 can be configured as a funnel-shaped structure or other structures.

[0034] In this example, if figure 1 As shown, the housing 200 is a cavity structure, which is connected to the bottom of the containing unit 100. There are two intermeshing gears in the cavity of the pressing unit 200, which are respectively the driving gear 210 on the left and the driven gear 220 on the right. ...

Embodiment 2

[0038]The present embodiment adopts the device of embodiment 1 to press and process pepper. Before pressing, the pepper to be pressed must be pre-cooled in a -80°C refrigerator for 30 minutes. During the pressing process, the pre-cooled pepper grains are placed in the container unit 100, and under the action of the valve 110, the pepper is pressed at a speed of one pepper at a time while the gears are engaged. During the pressing process, because the teeth of the two meshing gears are in full contact with the corresponding position of the groove of the other gear during the meshing process, that is, the surface 211 is in full contact with the surface 221, and the surface 212 is in full contact with the surface 222. 213 is in full contact with surface 223, so no matter the peppercorns fall on the surface 213 of the gear, or the surface 212, or the surface 221 (that is, no matter where the spices fall on the gear), they can be fully squeezed to achieve breaking. The effect of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com