Check sheet feeding device and control method thereof

A kind of non-return sheet and controller technology, which is applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of poor stability of automatic feeding mechanism, avoid interruption of supply, avoid slow supply, and maintain stable supply speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

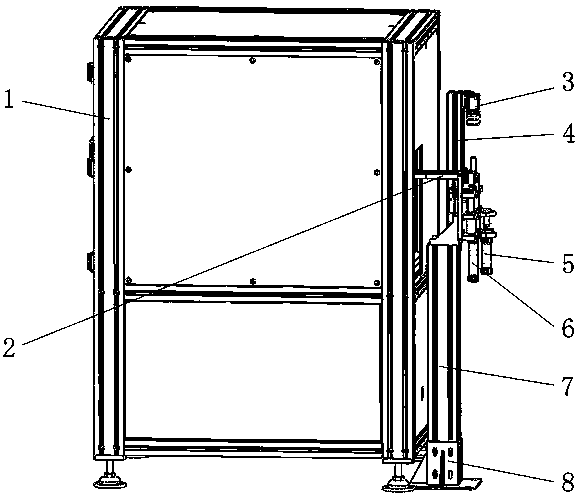

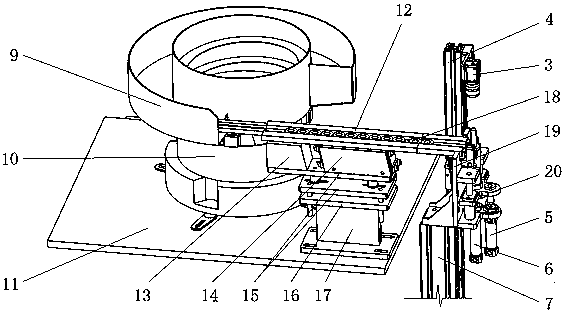

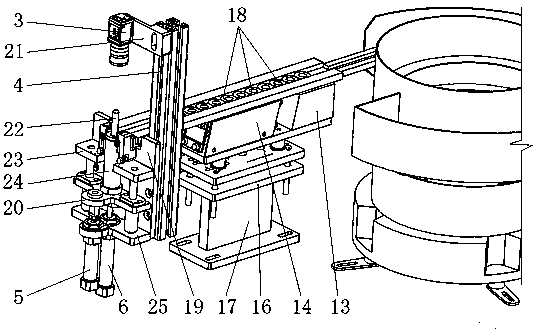

[0025] A non-return piece 18 feeding device, used for the non-return piece 18 feeding of the automatic assembly line of the water pump with assembly robot, such as figure 1 As shown, the present embodiment comprises frame 1, feeding vibrating plate 9, feeding direct vibration, feeding mechanism, detection device and controller, feeding vibrating plate 9 and feeding direct vibrating are all installed on the frame 1, feeding vibrating plate 9 It includes a storage bin for storing the non-return sheet 18, and a vibrating plate connected to the outlet of the storage bin. The end of the vibrating plate is connected to the feeding direct vibration. The feeding mechanism is located at the end of the feeding direct vibration, and the feeding direct vibration is close to the feeding mechanism. One end is slightly lower than the end close to the vibrating plate, the detection device is located above the feeding mechanism, and the detection mechanism detects the direction of the non-retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com