Vacuum adsorption fixture for radome

A technology of vacuum adsorption and radome, applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problems of manual centering, waste of processing time, etc., and achieve the effect of speeding up the completion speed, facilitating adsorption, and reducing the scope of activities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

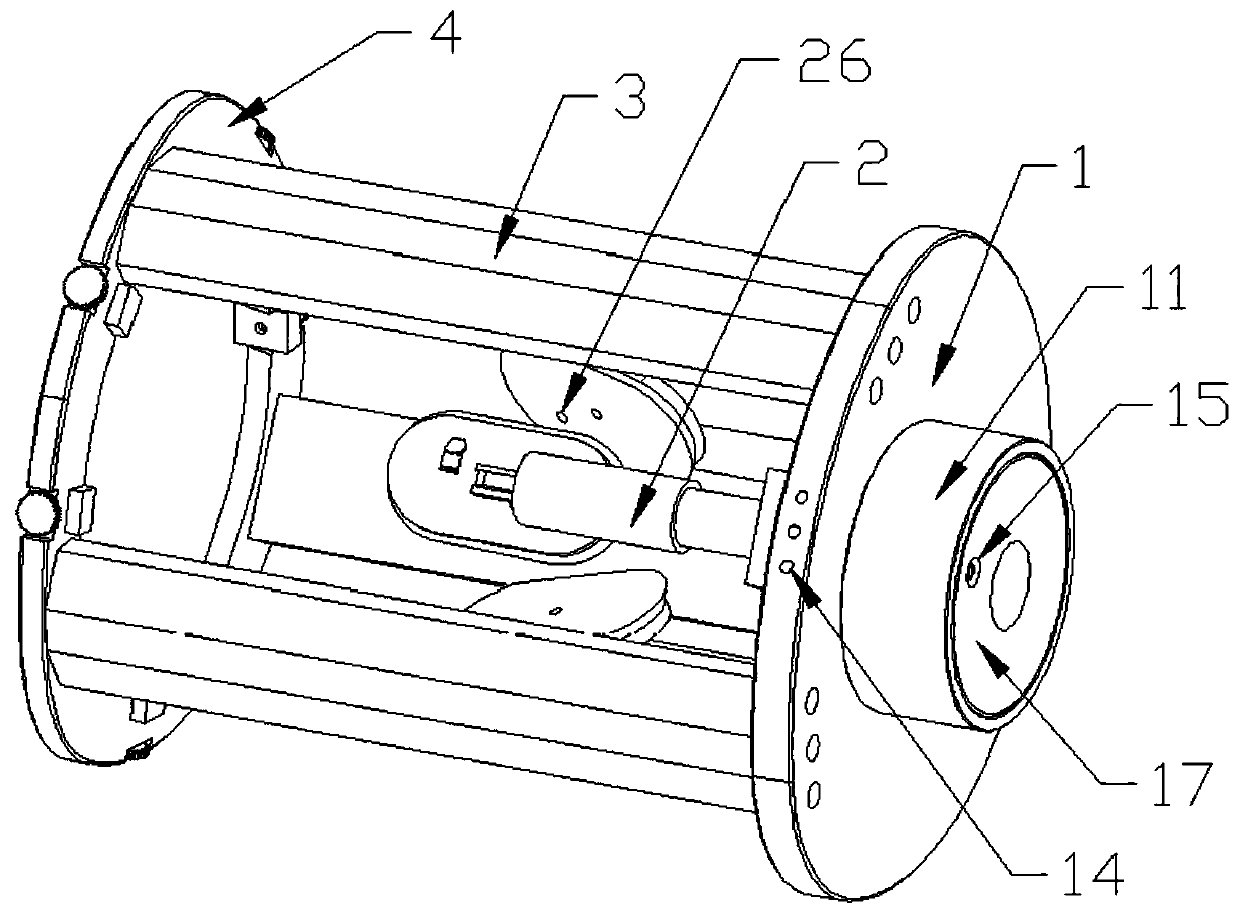

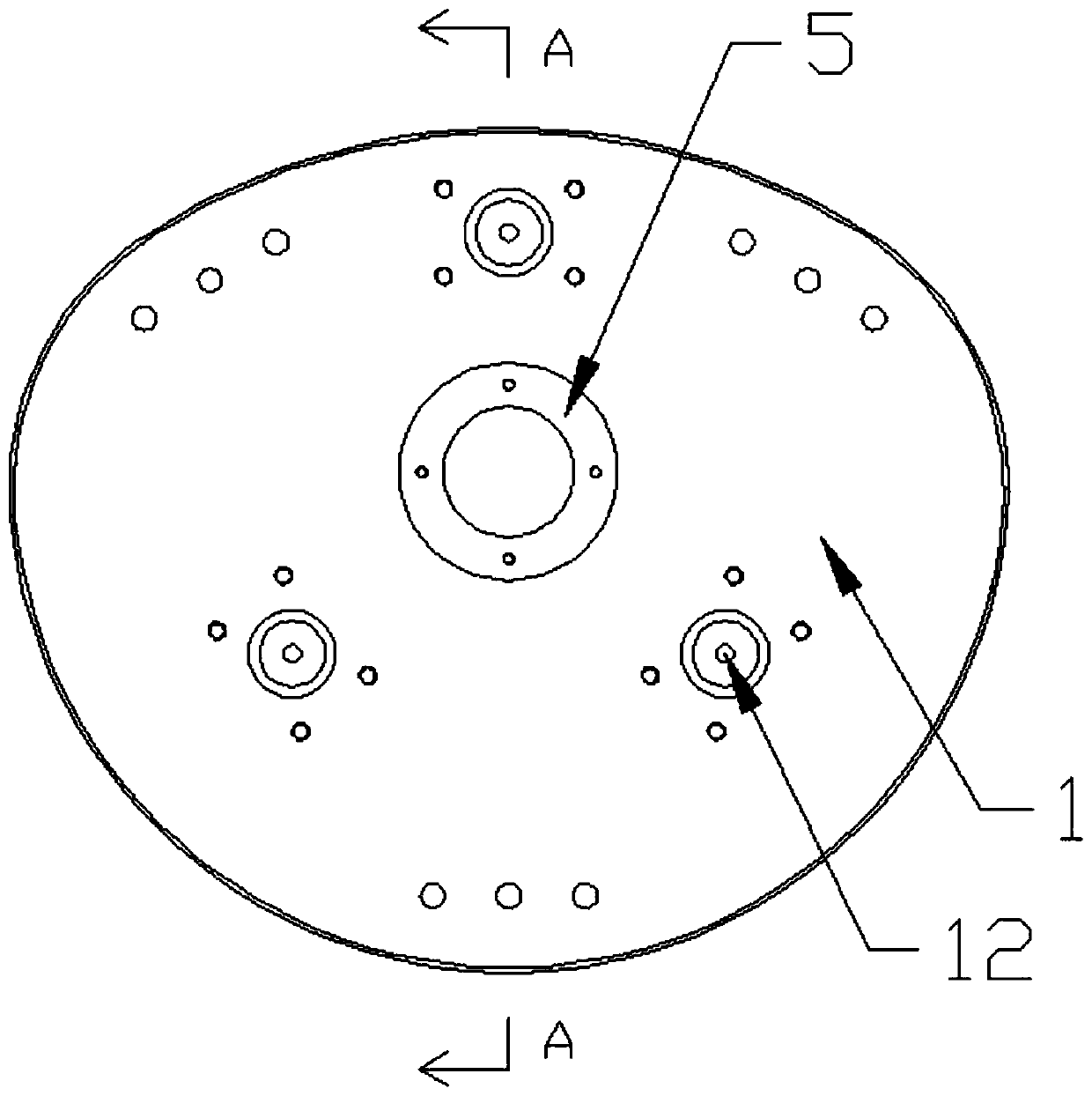

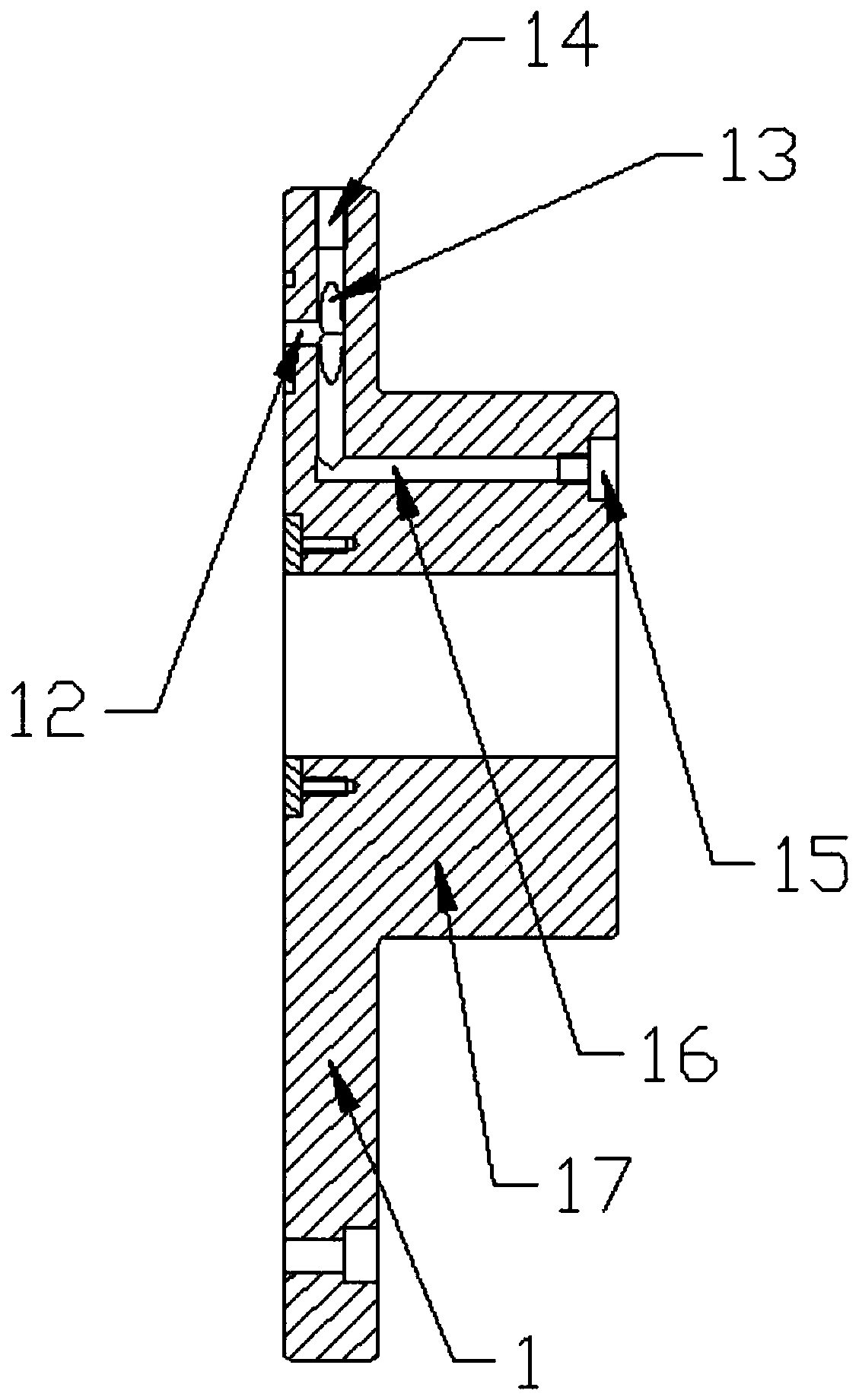

[0023] Such as Figure 1 to Figure 5 As shown, a radome vacuum adsorption fixture includes a fixture body, and the fixture body is composed of at least three adsorption assemblies 2; the adsorption assembly 2 includes a suction cup 21 and an air cylinder; the bottom surface of the suction cup 21 is provided with an air inlet 26 , the top surface is provided with a suction cup trachea joint 22 communicating with the air inlet 26; the cylinder body of the gas cylinder is provided with a gas cylinder trachea joint 23, one end of the gas cylinder is hinged with the top surface of the suction cup 21, and the other end is fixed on the bottom surface of the support frame 1; The top surface of the support frame 1 has a protruding base 17, and the bottom surface of the support frame 1 is provided with three supports 3 surrounding the outside of the adsorption assembly 2, and the bottom surface is also provided with air holes 12 corresponding to the holes at the bottom of the gas cylinde...

Embodiment 2

[0027] In order to avoid that the sucker and the radome are not firmly adsorbed, the gas cylinder includes a first cylinder body 24 and a second cylinder body 25, the first cylinder body 24 is provided with a gas cylinder trachea connector 23, one end of which is hinged to the top surface of the suction cup 21, The other end is slidingly connected with the second cylinder 25 , and a compression spring is sleeved between the second cylinder 25 . When the air compressor is vacuuming, the air pressure in the air cylinder decreases, but due to the support of the pressure spring, the first cylinder and the second cylinder cannot slide relative to each other to contract. When the air pressure in the air cylinder is low to a certain level, the external air pressure can overcome the elastic force of the compression spring to compress the compression spring, so that the first cylinder body shrinks towards the second cylinder body, which proves that the vacuum degree in the air cylinder ...

Embodiment 3

[0030] Such as Figure 6 As shown, in order to speed up the center alignment speed of the clamp and the radome, the outer ring of the collar 4 is provided with six sets of grooves opposite to the inner ring, and the grooves on the outer ring are provided with an adjusting screw 41, and the adjusting screw 41 is connected with the pressure block 42 arranged on the groove of the inner ring through the through holes on the bottom surface of each group of grooves. When the ring is placed outside the radome and the six pressure blocks are in contact with the surface of the radome, turn the six adjusting screws respectively to change the position of the pressure blocks in the inner ring, and then let the pressure blocks push the radome to move in the ring , until it is aligned with the center of the jig, and then the pressing blocks are clamped with the radome, and then the vacuuming work is carried out.

[0031] By adjusting the position of the screw rod and the pressing block, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com