Integrated glass fiber reinforced plastic tank vertical curing furnace

A glass fiber reinforced plastic tank and curing furnace technology, applied in the field of curing furnace, can solve the problems of unstable temperature control process, low efficiency, waste of time, low space utilization, etc., and achieve the effect of easy process connection, high curing efficiency and stable heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

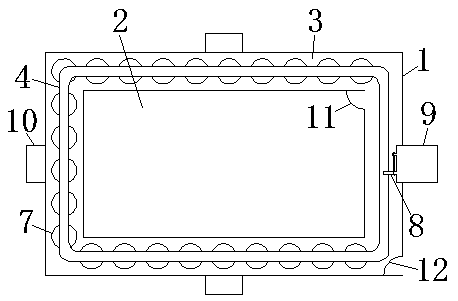

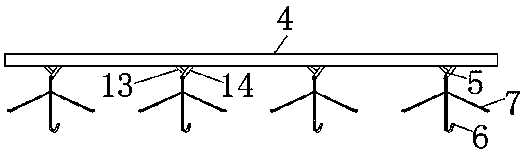

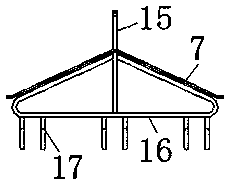

[0014] like figure 1 , figure 2 and image 3 As shown, the vertical curing furnace for integrated glass fiber reinforced plastic tanks according to the present invention comprises a body of furnace 1, in which body of furnace 1 is provided with a winding work area 2, between the body of furnace 1 and the work area of winding For the curing area 3, a track 4 is provided in the curing area 3, an endless chain is arranged on the track 4, a connecting assembly 5 is provided at the bottom of the endless chain, and a hook is provided at the bottom of the connecting assembly 5 Part 6, an umbrella-shaped baffle 7 is arranged on the upper part of the hook part 6, the endless chain is connected with the speed reducer 9 through a transmission mechanism 8, and at least one air duct 10 is provided on the furnace body 1, and the The winding work area 2 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com