Outer drum bearing supporting structure and washing machine

A technology of bearing support and bearing support seat, which is applied in the field of bearing support, can solve the problems of complex structure and shape of bearing support seat, high manufacturing cost, and large overall external size, and achieve the effects of simplifying structure, improving strength and reducing external size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

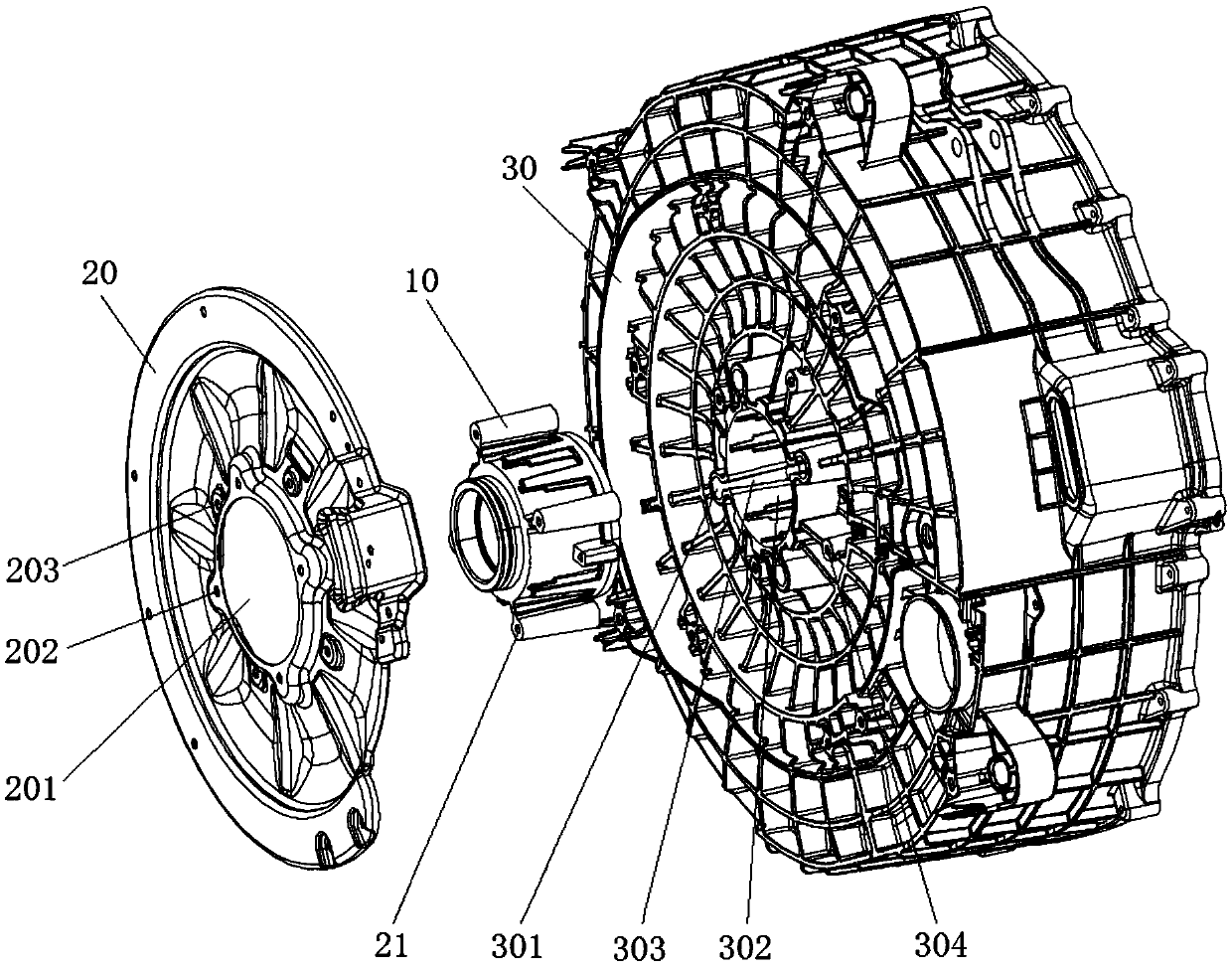

[0024] The invention provides an outer cylinder bearing support structure, such as figure 1 As shown, the outer cylinder bearing support structure includes a bearing support seat 10 and a reinforcement plate 20, wherein the bearing support seat 10 is embedded in the middle position of the rear part of the outer cylinder 30 of the washing machine, the reinforcement plate 20 is fastened on the back of the outer cylinder 30, and strengthens At the same time, the plate 20 is firmly connected with the above-mentioned bearing support seat 10 .

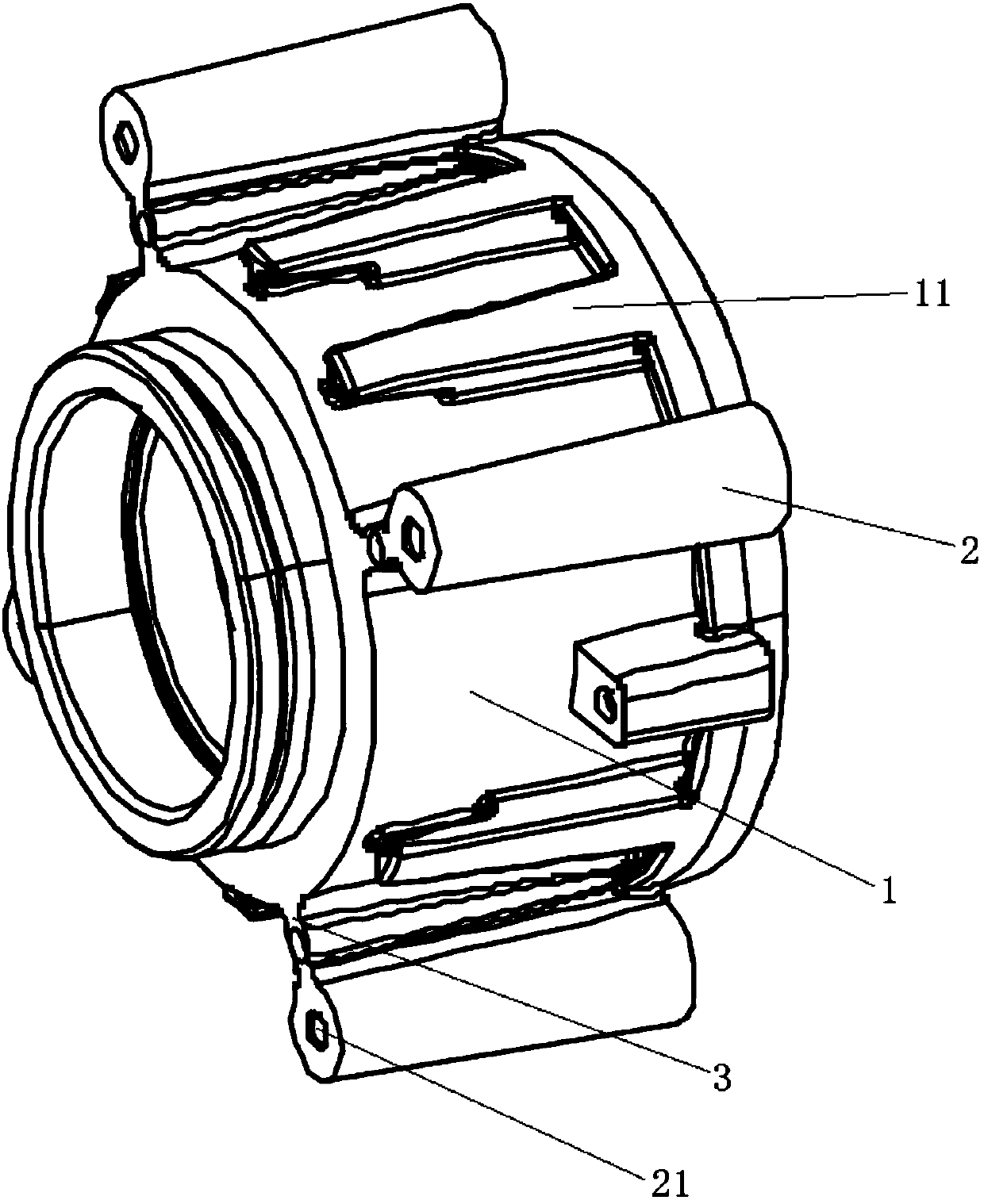

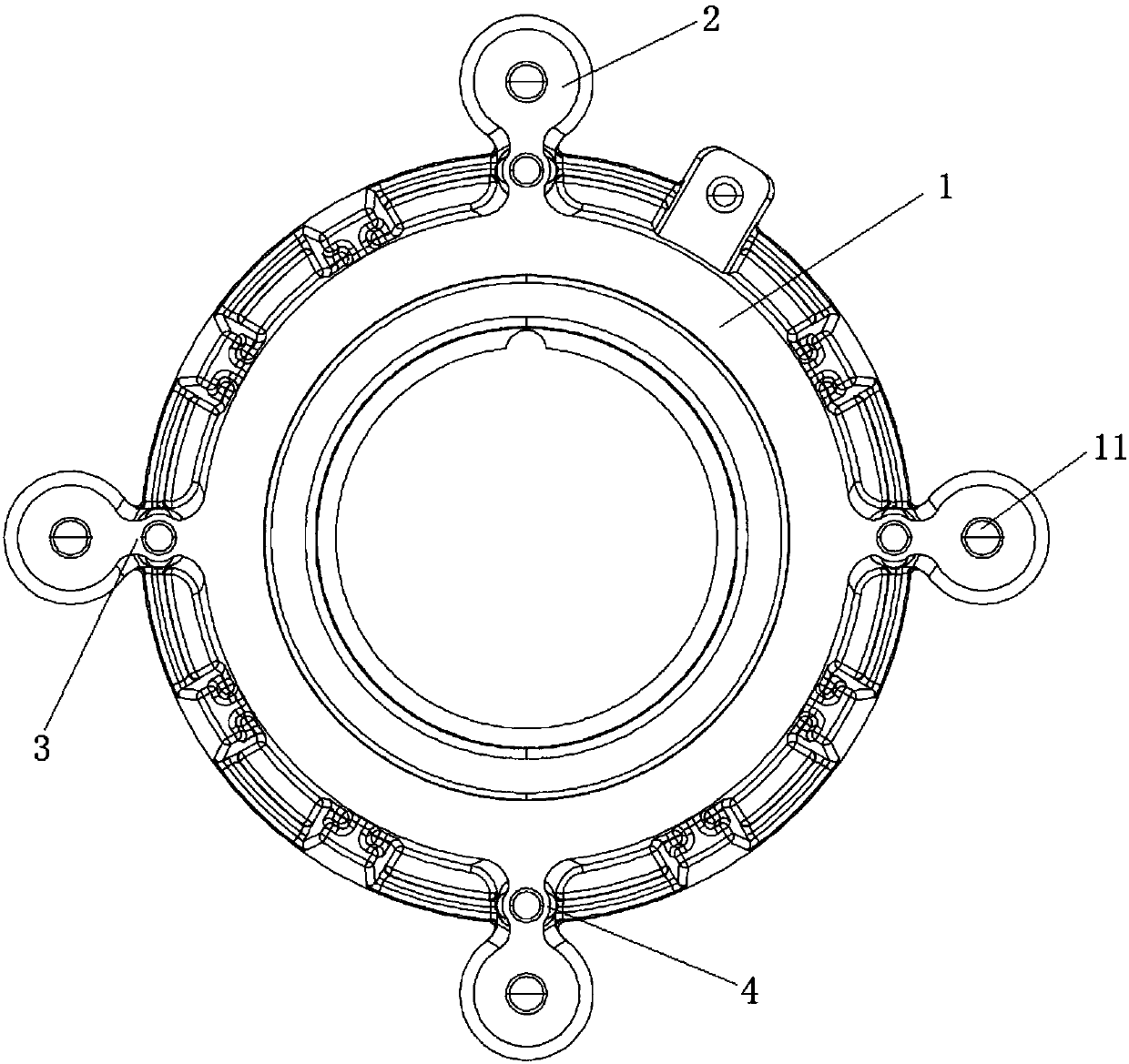

[0025] In this example, if figure 2 and image 3 As shown, the bearing support 10 includes a support body 1 with a cylindrical structure and a hole in the middle, and at least two fixing columns 2 circumferentially arranged on the outer wall of the support body...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap