Contact-type and non-contact-type sensors and electricity inspecting method adopting same

A non-contact and contact technology, applied to instruments, alarms, measuring electrical variables, etc., can solve problems such as personal safety accidents of maintenance personnel, property losses of the country and the people, and easy false alarms, so as to ensure safety and improve Credibility and reliability, overcoming the effect of rejecting the alarm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

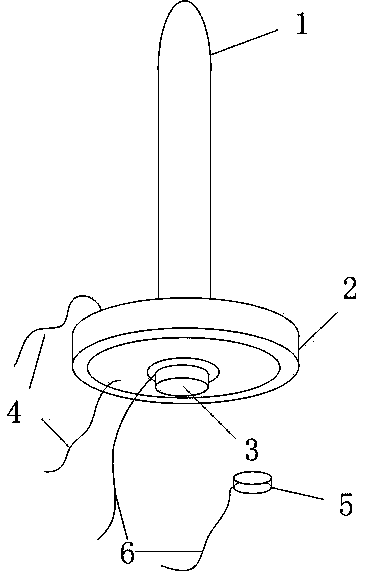

[0048] Such as figure 1 as shown, figure 1 It is the structure diagram of the sensor of the present invention. Its sensor of the electroscope of the present invention adopts the mode that metal contact probe 1 and plate capacitive electric field sensor 2 are combined, and wherein two sensors work independently, after contact probe 1 contacts charged object, the miscellaneous between contact probe 1 and electroscope ground 5 The bulk capacitance is divided into a voltage, which is used for the detection of the subsequent contact signal conditioning circuit. The contact probe outputs a voltage through the contact wire 6 and the electroscope ground 5 . The flat capacitive electric field sensor 2 is ring-shaped and is fixedly connected with the contact probe 1. One end of the contact probe 1 is inserted into the annular space in the middle of the flat capacitive electric field sensor 2 and is fixedly connected by a fixing bolt 3. The induced voltage of the flat capacitive elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com