Press machine upper cross beam robust optimization design method based on negative ideal solution close distance

A robust optimization, ideal unpaste technique for computer-aided design, constraint-based CAD, design optimization/simulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with accompanying drawing and example.

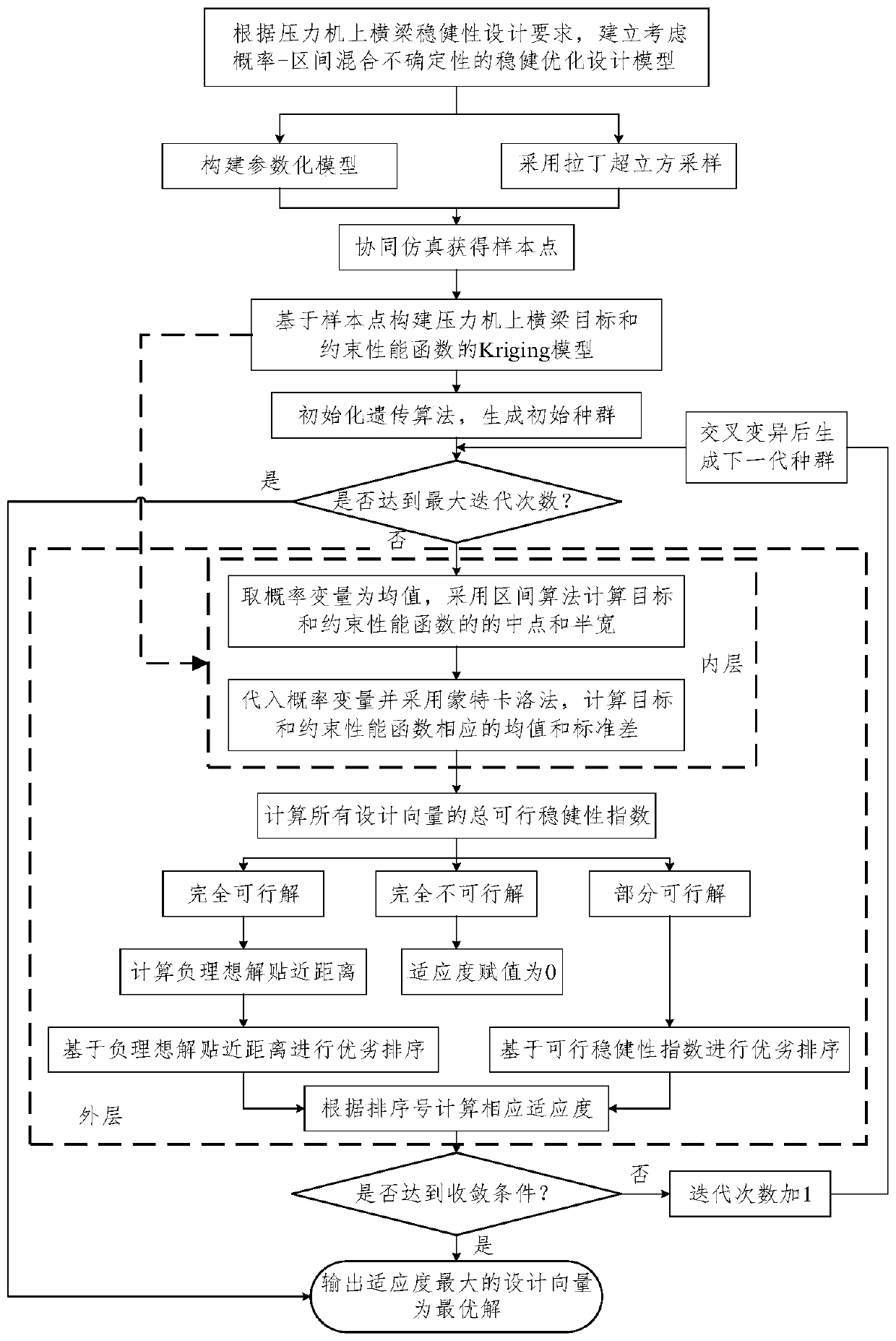

[0048] The information involved in the figure is the actual application data of the present invention in the robust design of the upper beam of a certain type of press, figure 1 It is a flow chart of the robust optimization design of the upper beam of the press based on the negative ideal solution close to the distance.

[0049] 1. Modeling of the robust optimal design of the upper beam of the press based on probability-interval mixed uncertainty:

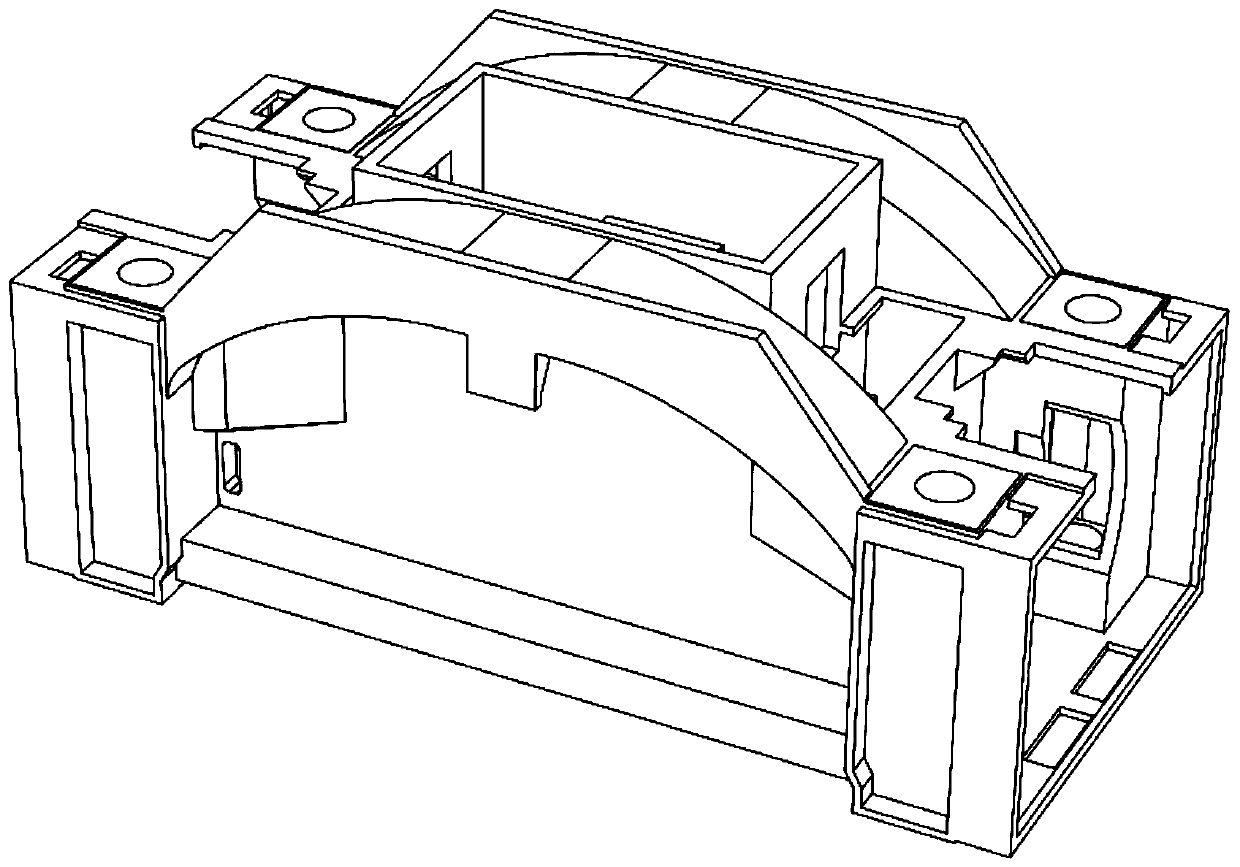

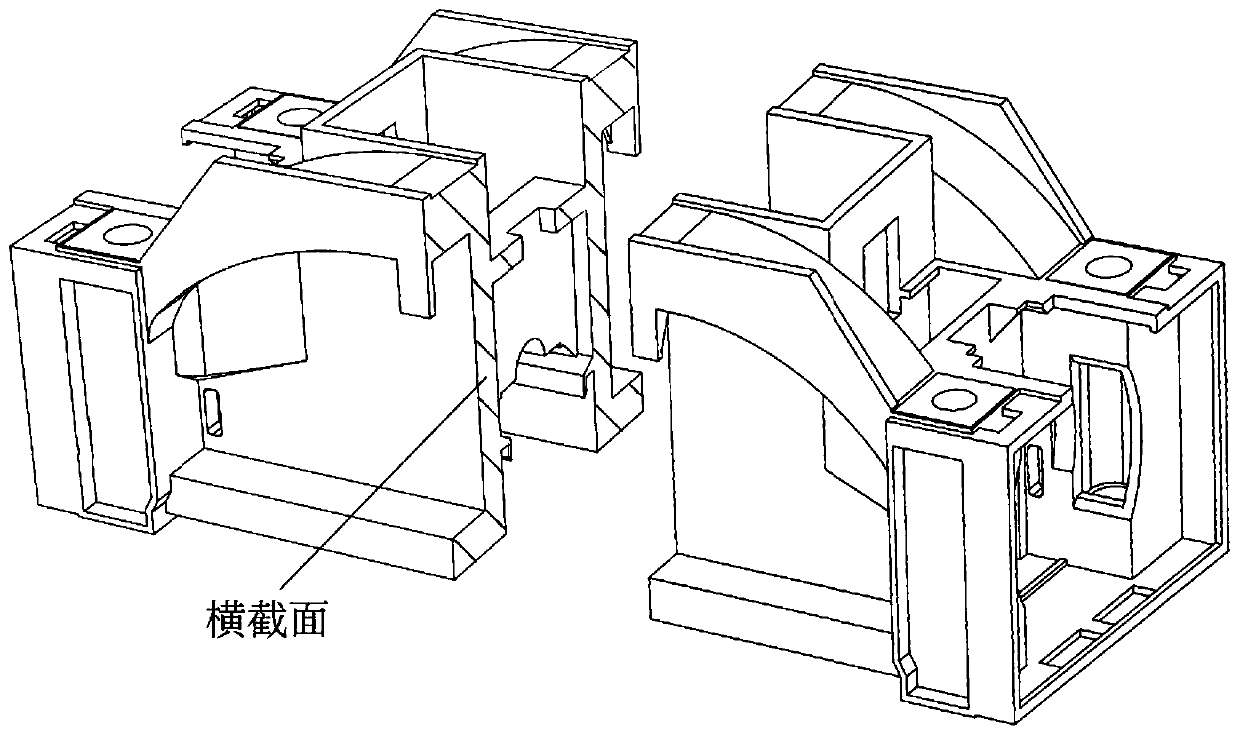

[0050] by figure 2 , 3 The upper beam of the punching machine shown as the research object, with Figure 4 The cross-sectional dimension h of the upper beam shown 1 , h 2 , l 1 , l 2 , l 3 As the design variable, the Figure 5 The external force P shown 1 ,P 2 ,P 3 Uncertainty factors are described as probability variables. At the same time, the uncertainty of the density ρ and Poisson's ratio ν of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com