A method for extracting and predicting equipment performance degradation trend

A technology of trend extraction and equipment performance, applied in design optimization/simulation, computer-aided design, etc., can solve problems such as accelerated component wear, unit damage, component fatigue damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

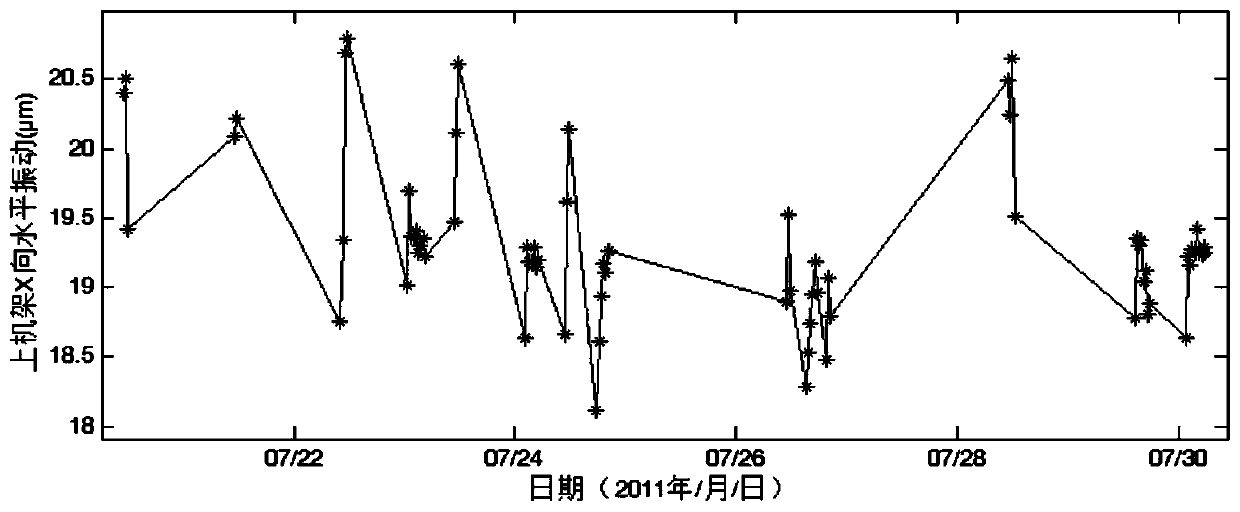

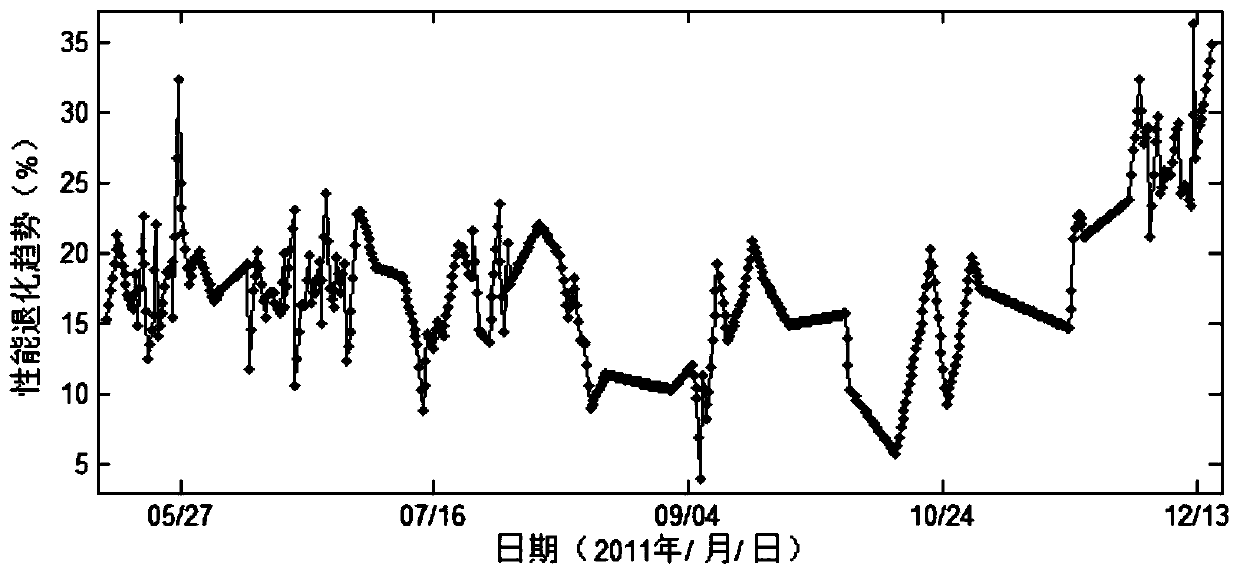

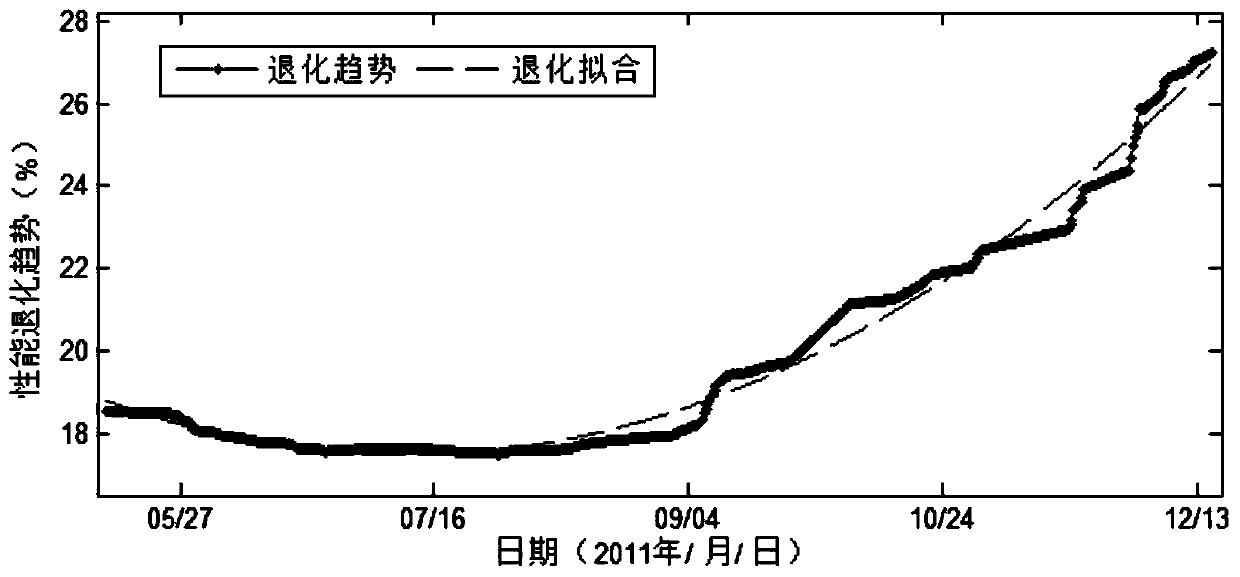

[0105] In this example, the actual measurement status monitoring data of a unit in a power station from September 22, 2008 to December 15, 2011 is used as a sample to verify the effectiveness of the method for extracting performance degradation trends of hydropower units based on inverse distance weighting and ITD. sex. The X-direction horizontal vibration data of the upper frame of the unit is selected as the research object. Due to the complex operating conditions of the generating set in this power station, the frequent starting and stopping of the generating set and the switching of working conditions, the monitoring data of this type of generating set can better reflect the effectiveness of the model proposed by the present invention under variable operating conditions. The X-direction horizontal vibration data of the upper frame of the unit is selected as the research object.

[0106] like figure 1 As shown, the measured data of the X-direction horizontal vibration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com