Double-layer electrically-charged waterway penetration piece used on fusion reactor atmosphere side

A technology of atmospheric side and penetrating parts, applied in fusion reactors, thermonuclear fusion reactors, nuclear reactors, etc., can solve problems such as harsh working environment, high temperature, radioactive radiation, thermal shock and mechanical shock, and failure to meet the needs of fusion reactor engineering , to meet the needs of the installation environment and space, and to ensure the effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

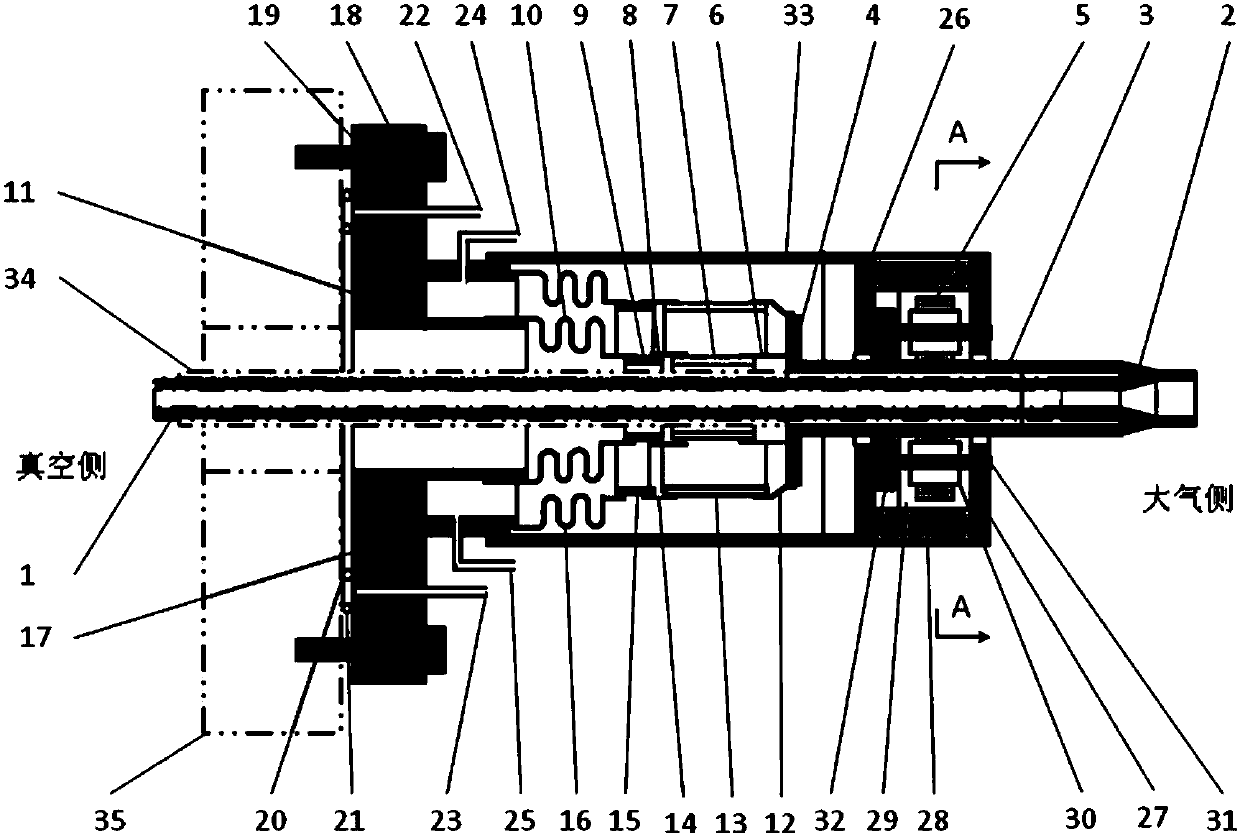

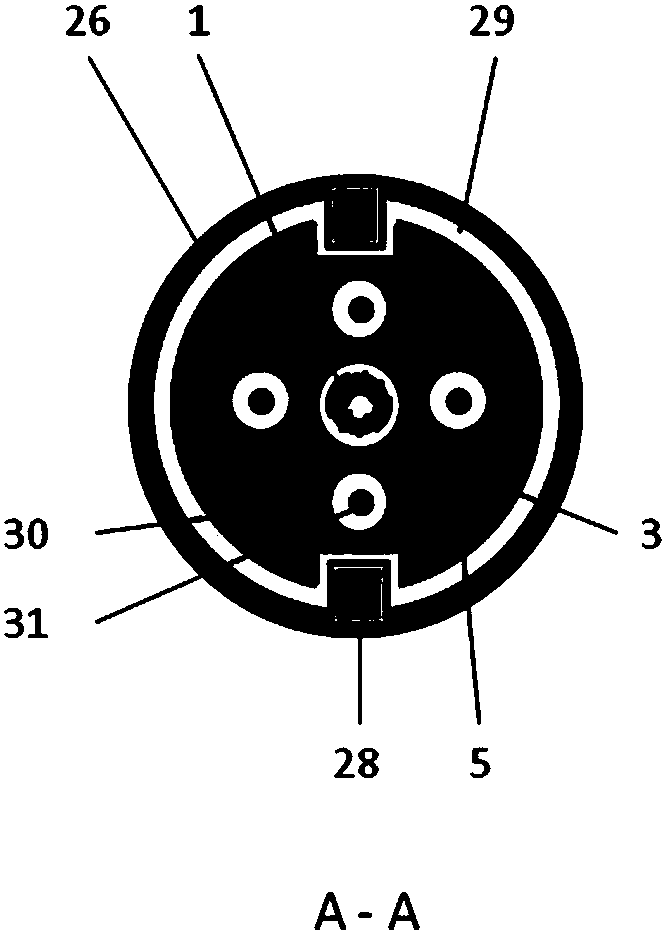

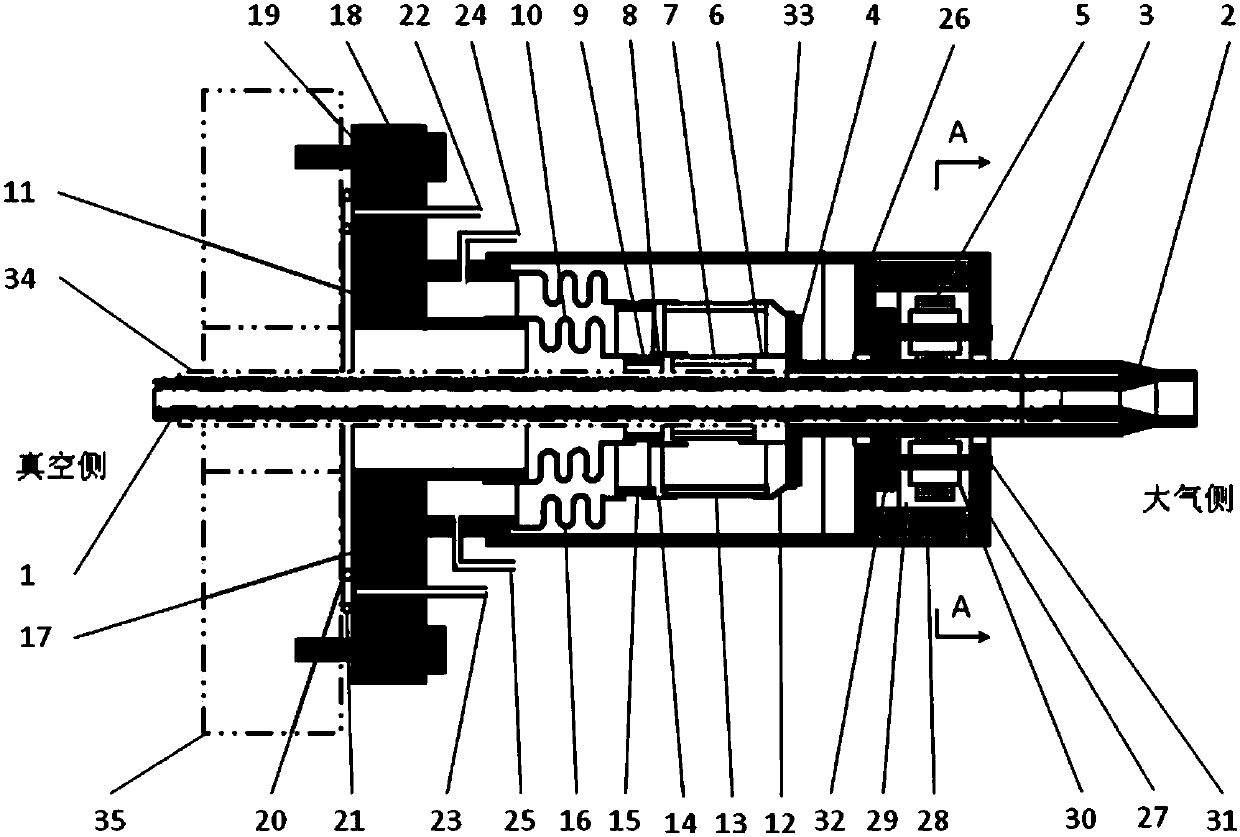

[0048] A double-layer electrified waterway penetrating piece for the atmosphere side of a fusion reactor according to the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0049] Such as figure 1 and figure 2 As shown, a double-layer charged waterway penetrating piece for the atmosphere side of a fusion reactor in the present invention includes: a first layer of electrical insulation constraint structure, a second layer of electrical insulation constraint structure, an ITER flange assembly, a live water pipe 1, and an outer casing 3 , the separator 4 and the fourth ceramic tube 34;

[0050] The first layer of electrical insulation constraint structure includes a first metal ring 6, a first ceramic tube 7, a second metal ring 8, an inner transition ring 9, an inner bellows 10 and an inner flange tube 11;

[0051] The left end of the first ceramic tube 7 is connected to the inner transition ring 9 through the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com