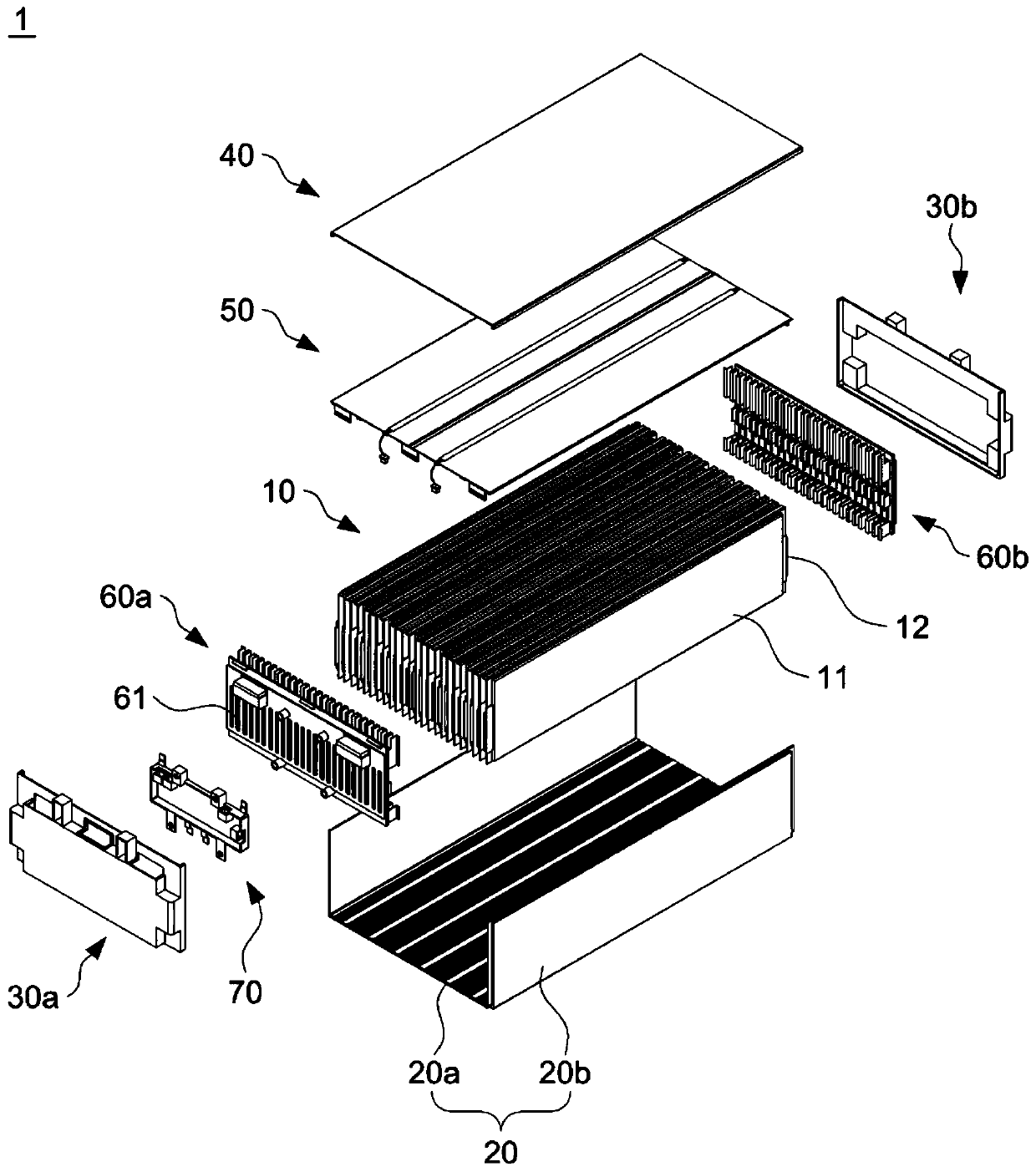

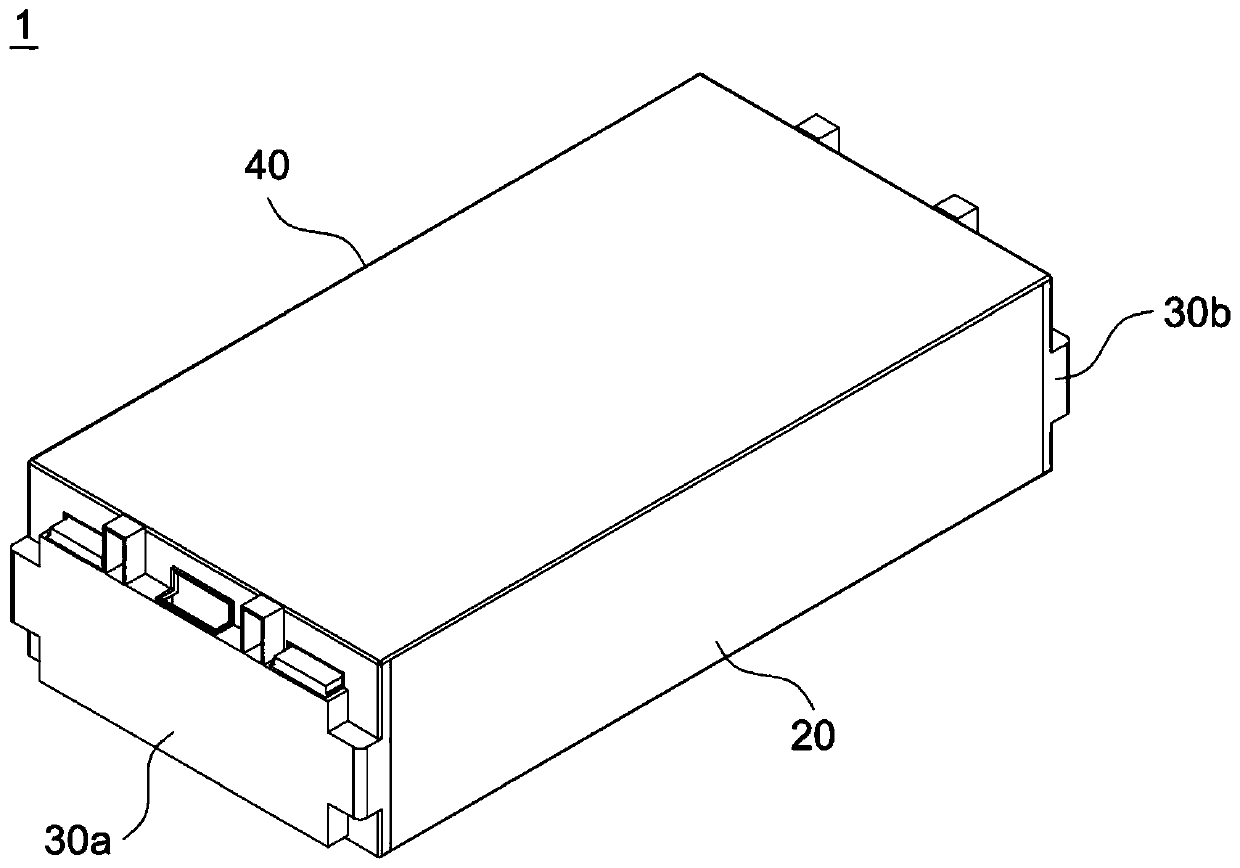

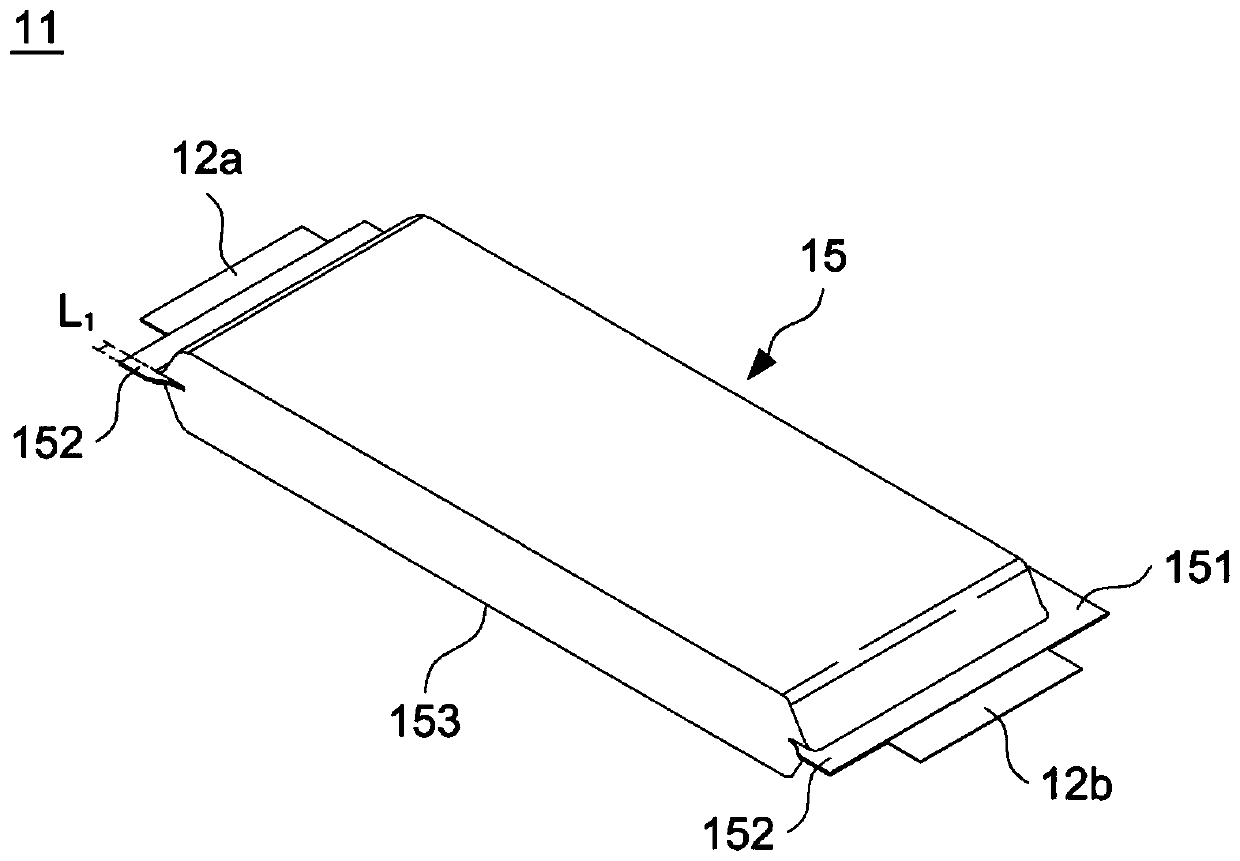

Battery module and its manufacturing method

A technology for battery modules and manufacturing methods, which is applied to secondary batteries, battery covers/end covers, battery pack components, etc., which can solve the problems of increased manufacturing time and cost, complicated module manufacturing process, and increased volume of battery modules, and achieve Improves assembly, maximizes heat transfer efficiency, and increases cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0106] Next, specific embodiments of the present invention will be described with reference to the drawings. However, this is only an example, and the present invention is not limited thereto.

[0107] When describing the present invention, when it is considered that the specific description of the known technology related to the present invention may unnecessarily obscure the gist of the present invention, its detailed description will be omitted. Also, terms described later are defined in consideration of functions in the present invention, and the terms may vary according to user, operator's intention, custom, or the like. Therefore, the terms should be defined based on the contents of the entire specification.

[0108] The technical idea of the present invention is determined by the claims, and the following embodiments are only a way to effectively explain the technical idea of the present invention to those of ordinary skill in the technical field to which the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com