Manufacture method of winding core and winding core

A manufacturing method and core technology, which can be used in final product manufacturing, secondary battery manufacturing, sustainable manufacturing/processing, etc., and can solve the problems of reducing battery energy density, incapable of fully utilizing the shell space, and difficulty in entering the core into the shell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the objectives, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and specific embodiments. Apparently, the described embodiments are some, not all, embodiments of the present invention. All other embodiments obtained by those skilled in the art based on the described embodiments of the present invention belong to the protection scope of the present invention.

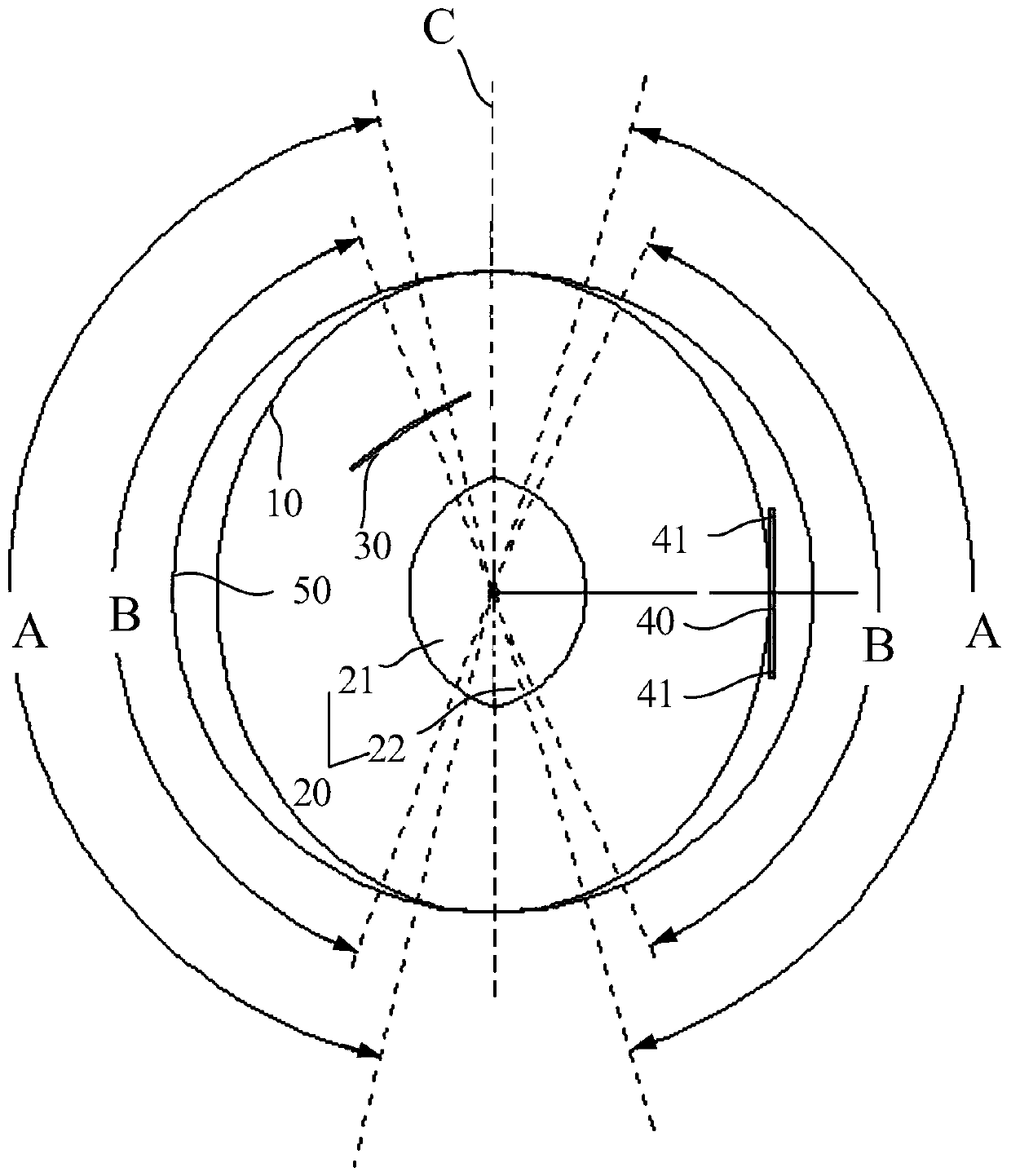

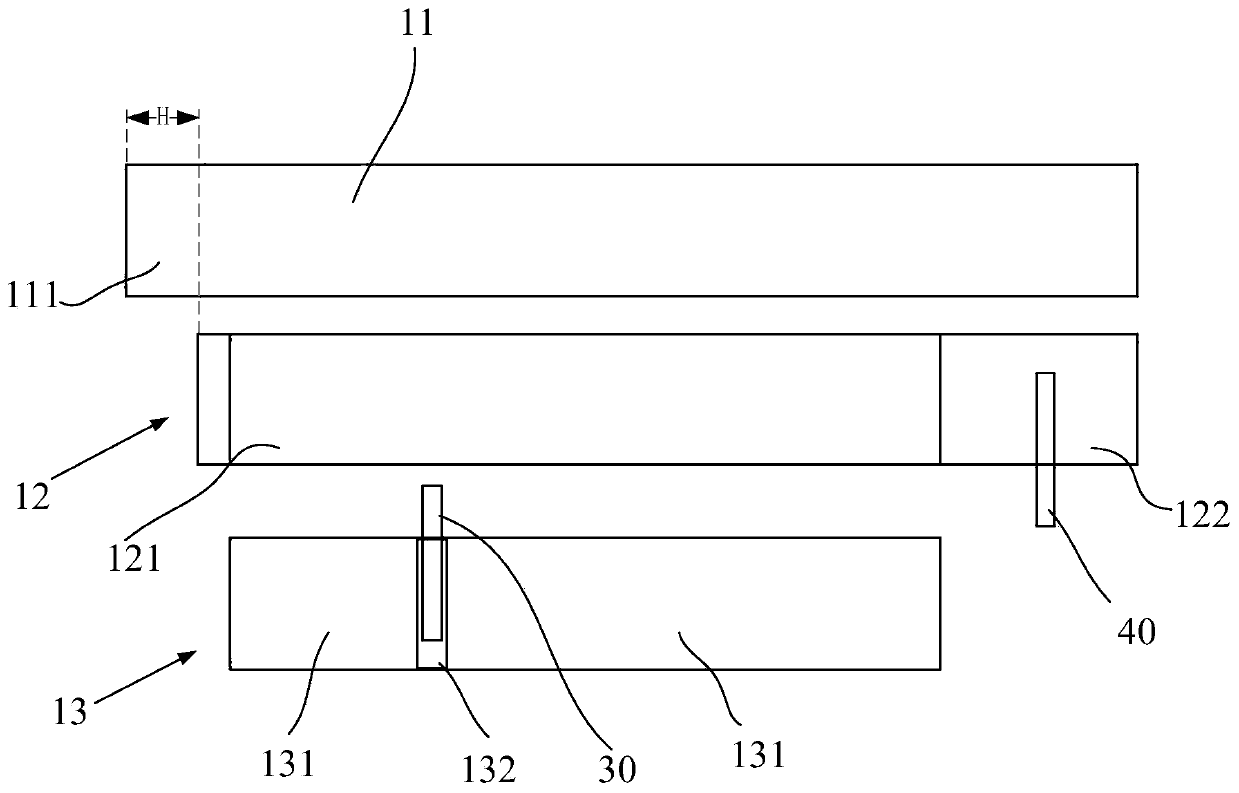

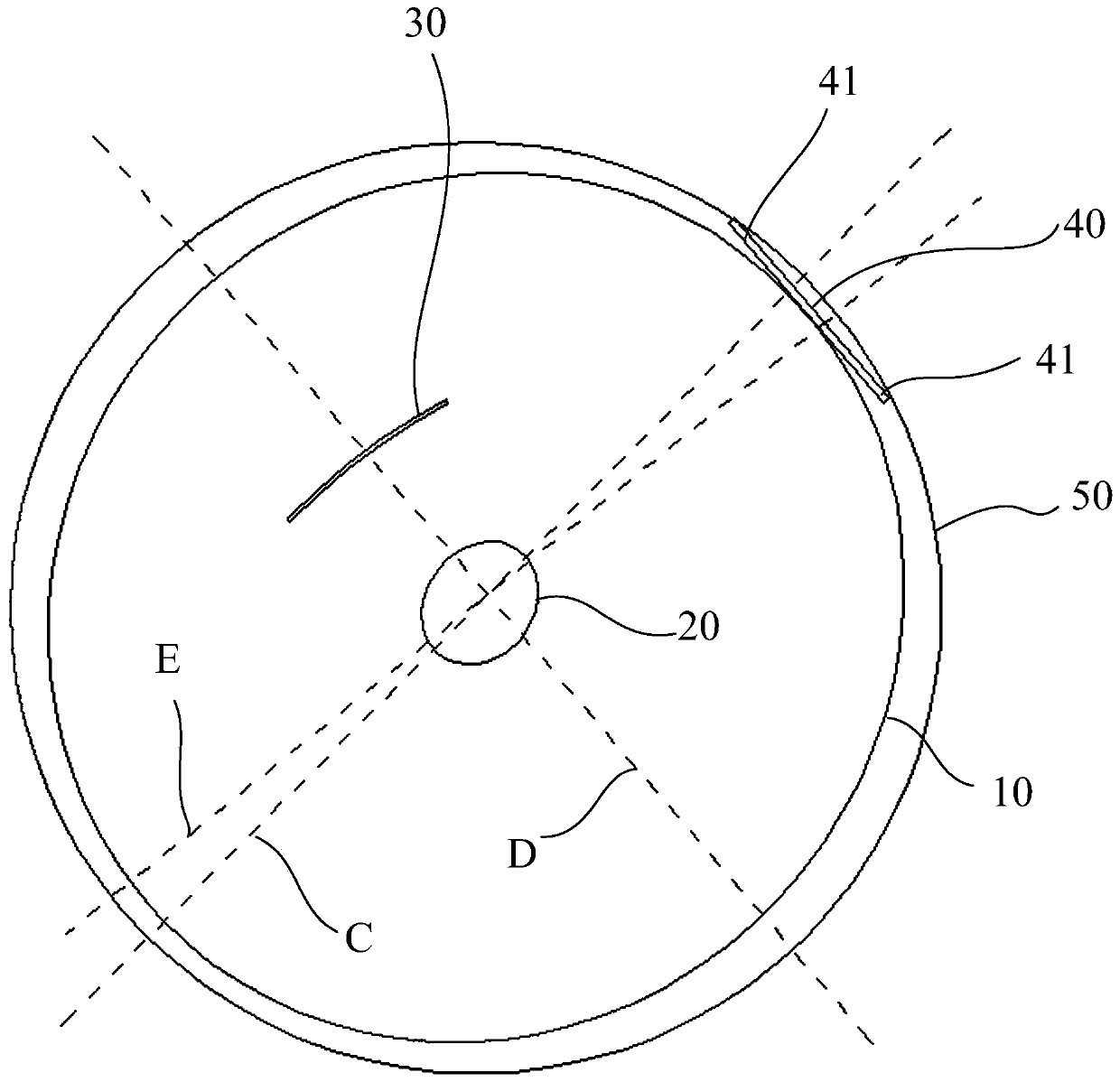

[0028] The winding core 10 in the embodiment of the present invention is suitable for cylindrical batteries, including but not limited to ternary batteries, lithium iron phosphate and other lithium ion batteries, such as 18650, 21700 and 26650 cylindrical batteries. The battery includes a winding core 10 and a positive electrode tab 30 and a negative electrode tab 40 connected to the winding core 10 . figure 1 , ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com