Temperature control method for barrel body of cut-tobacco drier

A control method and technology of a silk drying machine, which are applied in the fields of tobacco preparation, application, and tobacco, can solve the problems of adjustment lag and low accuracy, and achieve the effect of achieving accuracy and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the claimed protection scope is not limited to the description.

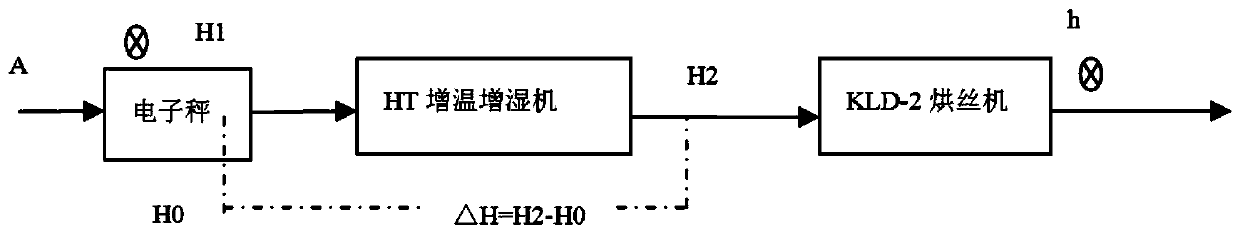

[0043] like figure 1 As shown, it is the KLD-2 silk drying process such as the process flow, in the figure On behalf of the online moisture meter, H0 is the oven method to detect the incoming moisture, H1 is the online moisture meter to display the incoming moisture, H2 is the oven method to detect the moisture at the outlet of the HT, h is the set value of the outlet moisture of the silk dryer, △H represents the moisture increase.

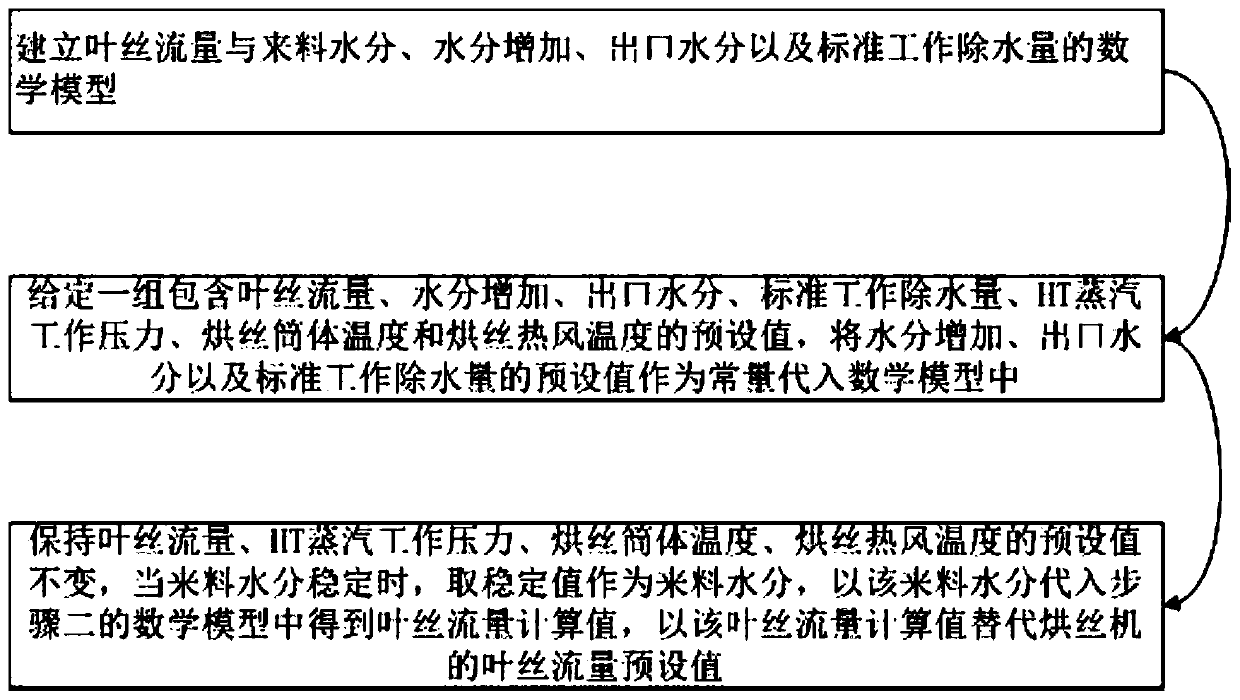

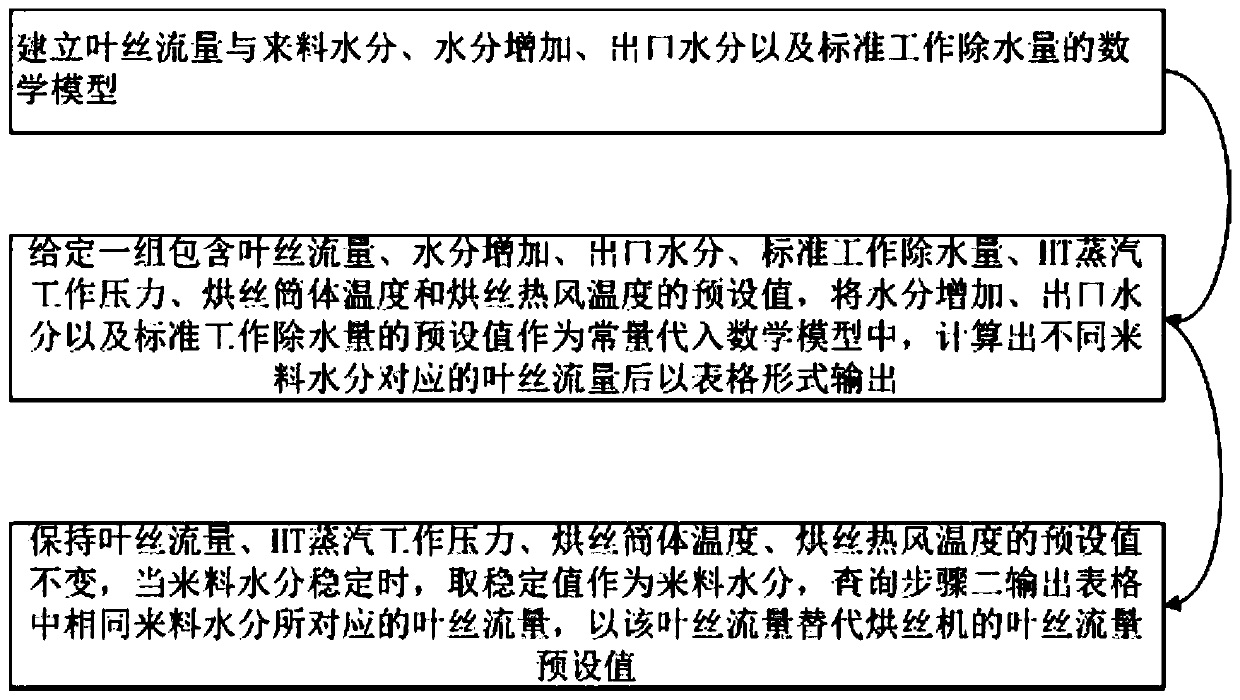

[0044] When adopting Microsoft Excel to cooperate in the present invention image 3 When the control method in the output form shown in the table is shown, its implementation process is as follows:

[0045] 1. Obtained through the brand standard: the moisture setting value h (%) at the outlet of the dried silk.

[0046] 2. Check the historica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com