Compound die capable of reducing blanking force for thick material connecting card

A composite mold and connecting card technology, which is applied in the field of stamping processing, can solve the problems of fast wear, high noise, and low production efficiency of blanking dies, and achieve the goals of preventing punch breakage, reducing noise decibels, and increasing leveling effects Effect

Pending Publication Date: 2019-07-12

HESHAN LESSO IND DEV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the molds used for parts generally use large punching machines, the cost of artificial water and electricity is relatively high, the noise is large, and the loss of the machine tool is large; during the punching process, the punch is easy to be broken or chipped; The material parts are uneven, and large burrs are easy to appear; the typing process is not combined with the blanking and punching, and two sets of dies are required for production, and the production efficiency is not high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

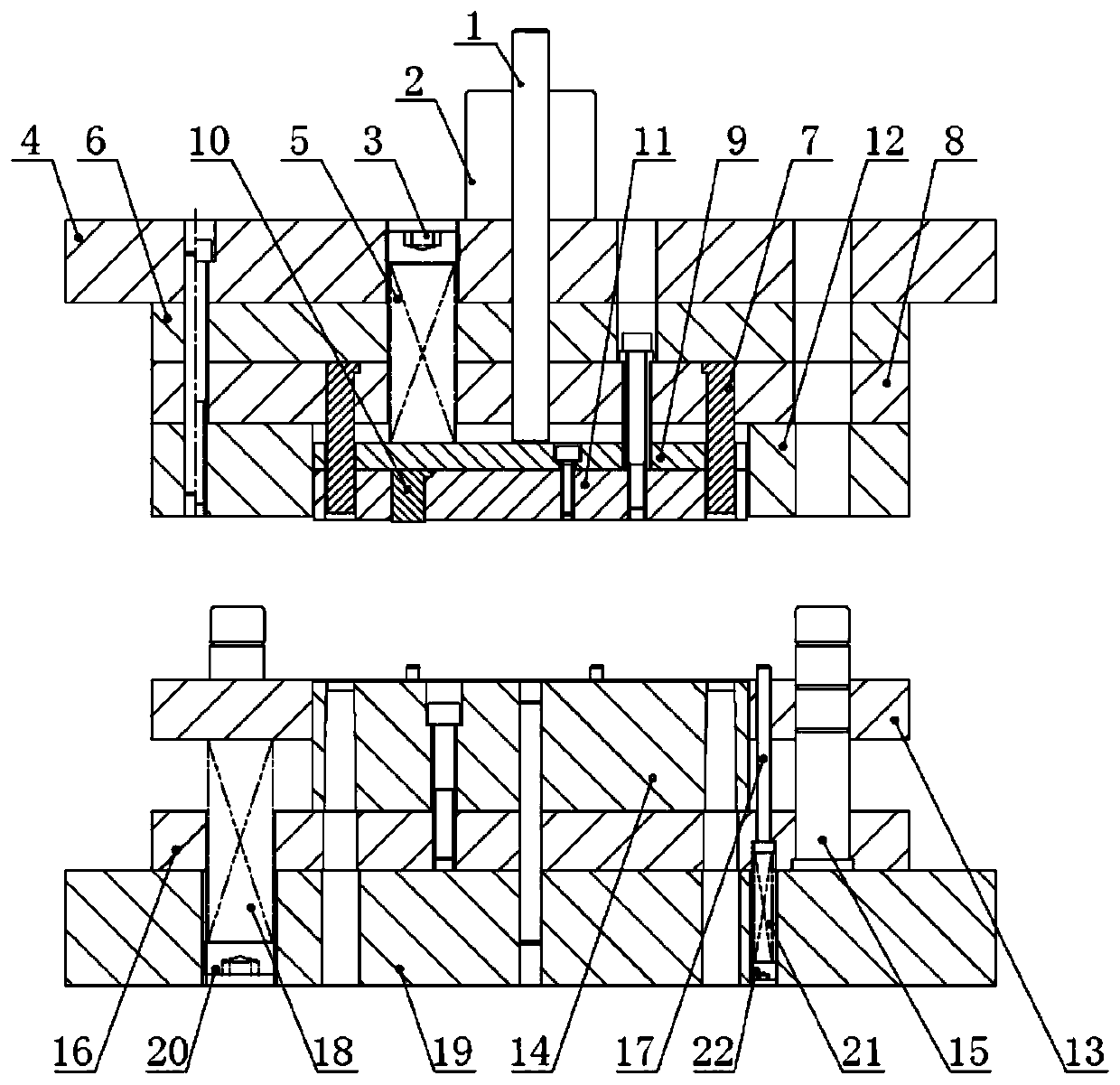

[0041] This embodiment is similar to Embodiment 1, the difference is that in this embodiment, the longitudinal section of the raised portion 121 is a right-angled trapezoid, and there are eight protrusions, which are respectively located at both ends of each side of the lower surface of the concave template 12, that is, Figure 4 The surface B becomes the highest surface, and the surface C becomes the lowest surface, which can also reduce the punching force.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to view more

Abstract

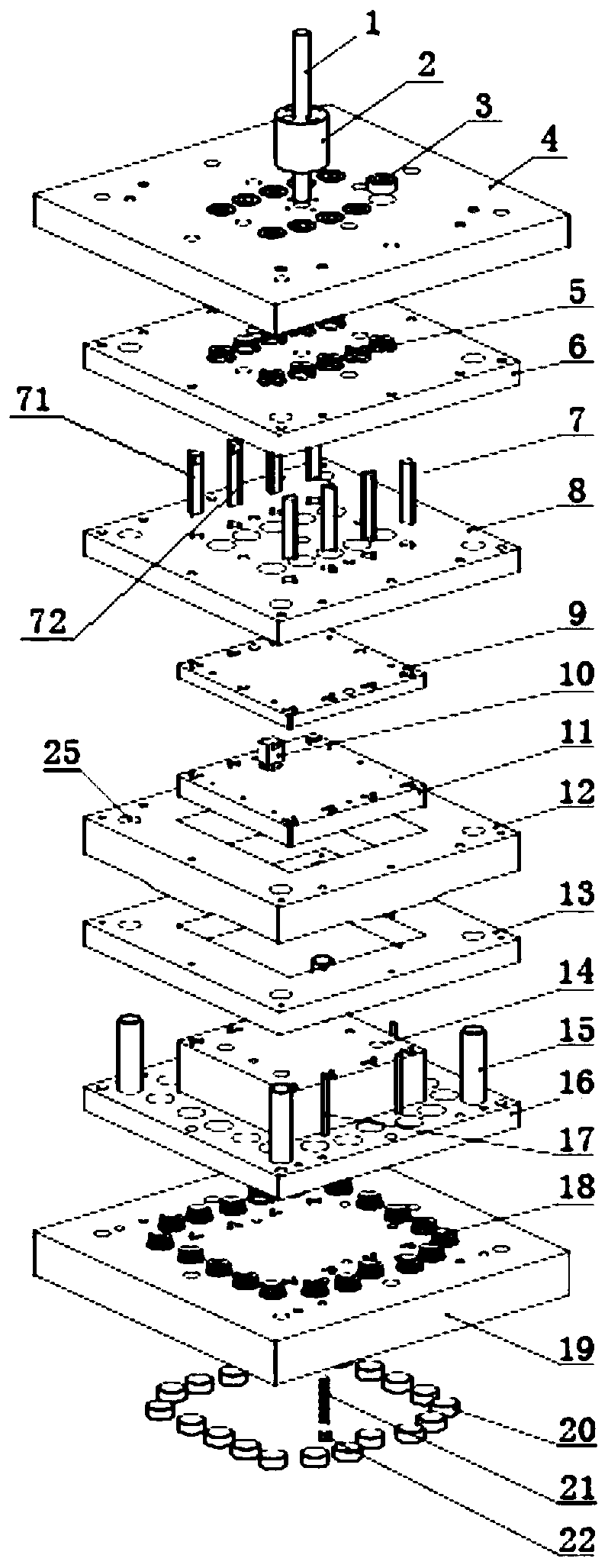

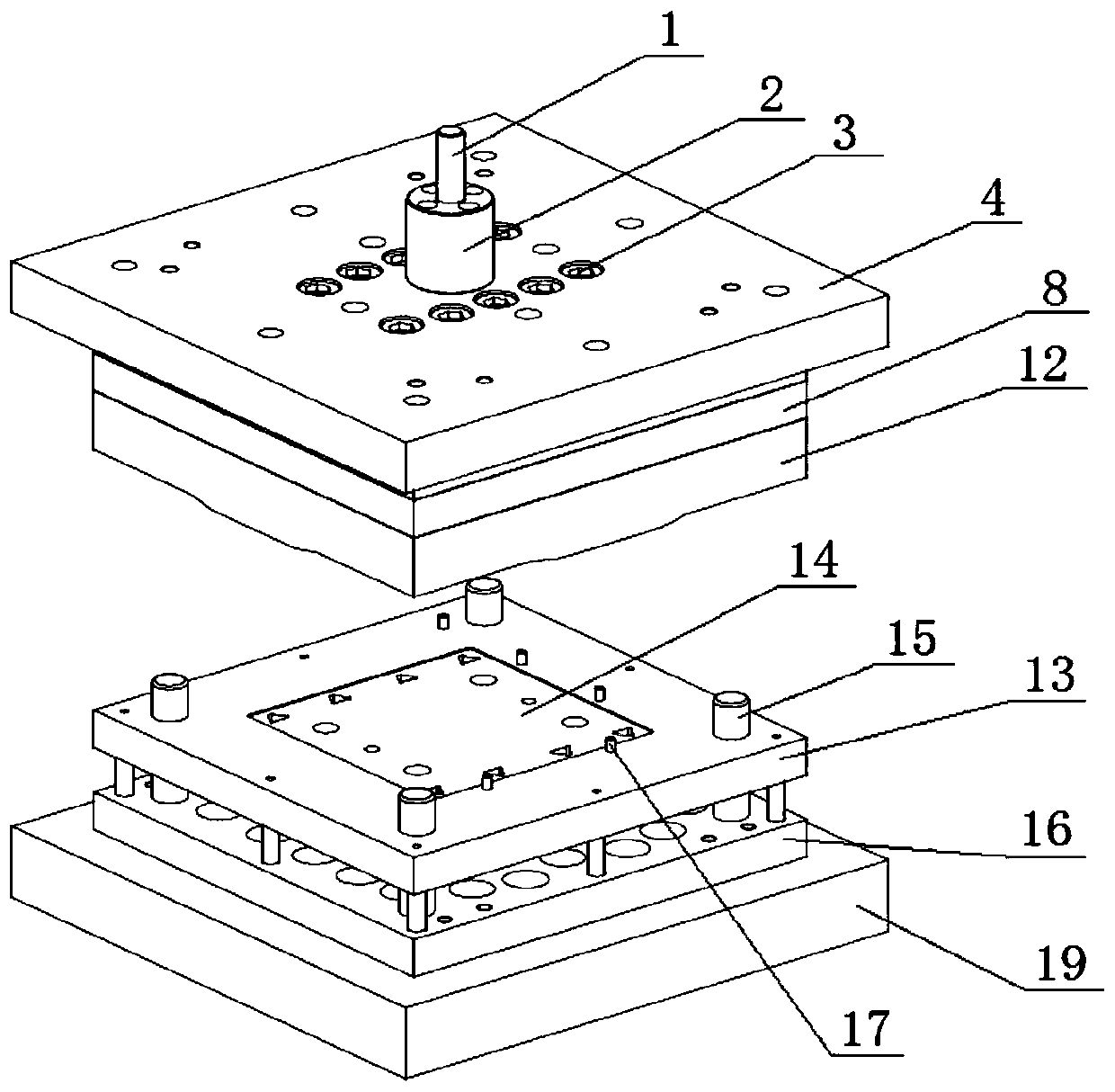

The invention relates to the technical field of stamping machining, and specifically provides a compound die capable of reducing blanking force for a thick material connecting card. The compound die comprises an upper die part and a lower die part, wherein the upper die part comprises an upper die base, an upper cushion plate and an upper die fixing plate arranged sequentially from top to bottom,and a first spring component is further arranged in the upper die part; the lower die part comprises a discharging plate, a lower die fixing plate and the a lower die base arranged sequentially from top to bottom, a convex die and a concave die are embedded in the discharging plate, and a second spring component is further arranged in the lower die part; the lower surface of the upper die fixing plate is provided with a concave die plate; the lower surface of the concave die plate is provided with a plurality of bosses; a returning component is arranged in the concave die plate; and a punch penetrates through the upper die fixing plate and the returning component. By means of the compound die capable of reducing blanking force for the thick material connecting card, the blanking force andthe noise decibel generated by the stamping operation can be reduced, and the service life of the die is prolonged; and the costs of labor and material can be reduced, the production efficiency of products is improved, and parts can be produced quickly at one time.

Description

technical field [0001] The invention relates to the technical field of stamping processing, and more specifically, provides a composite mold for reducing punching force of a thick-material connection card. Background technique [0002] There are various styles and structures of hardware accessories circulating in the market. Among them, there is a siphon type roof rainwater drainage suspension system accessory connection card, which is used together with common pipe clips and is in great demand. At present, the molds used for parts generally use large punching machines, the cost of artificial water and electricity is relatively high, the noise is large, and the loss of the machine tool is large; during the punching process, the punch is easy to be broken or chipped; The material parts are not flat, and large burrs are prone to appear; the typing process is not combined with the blanking and punching, and two sets of dies are required for production, and the production effic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): B21D37/10B21D37/12B21D45/08B21D28/34B21D28/14B21C51/00

CPCB21D37/10B21D37/12B21D45/08B21D28/34B21D28/14B21C51/00

Inventor 雷世俊

Owner HESHAN LESSO IND DEV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap