Charging gun for new-energy electric vehicle

A technology for electric vehicles and charging guns, which is applied in electric vehicle charging technology, electric vehicles, charging stations, etc., can solve problems such as electric ignition, and achieve the effects of protecting circuits, accelerating heat dissipation, and improving heat flow exchange capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

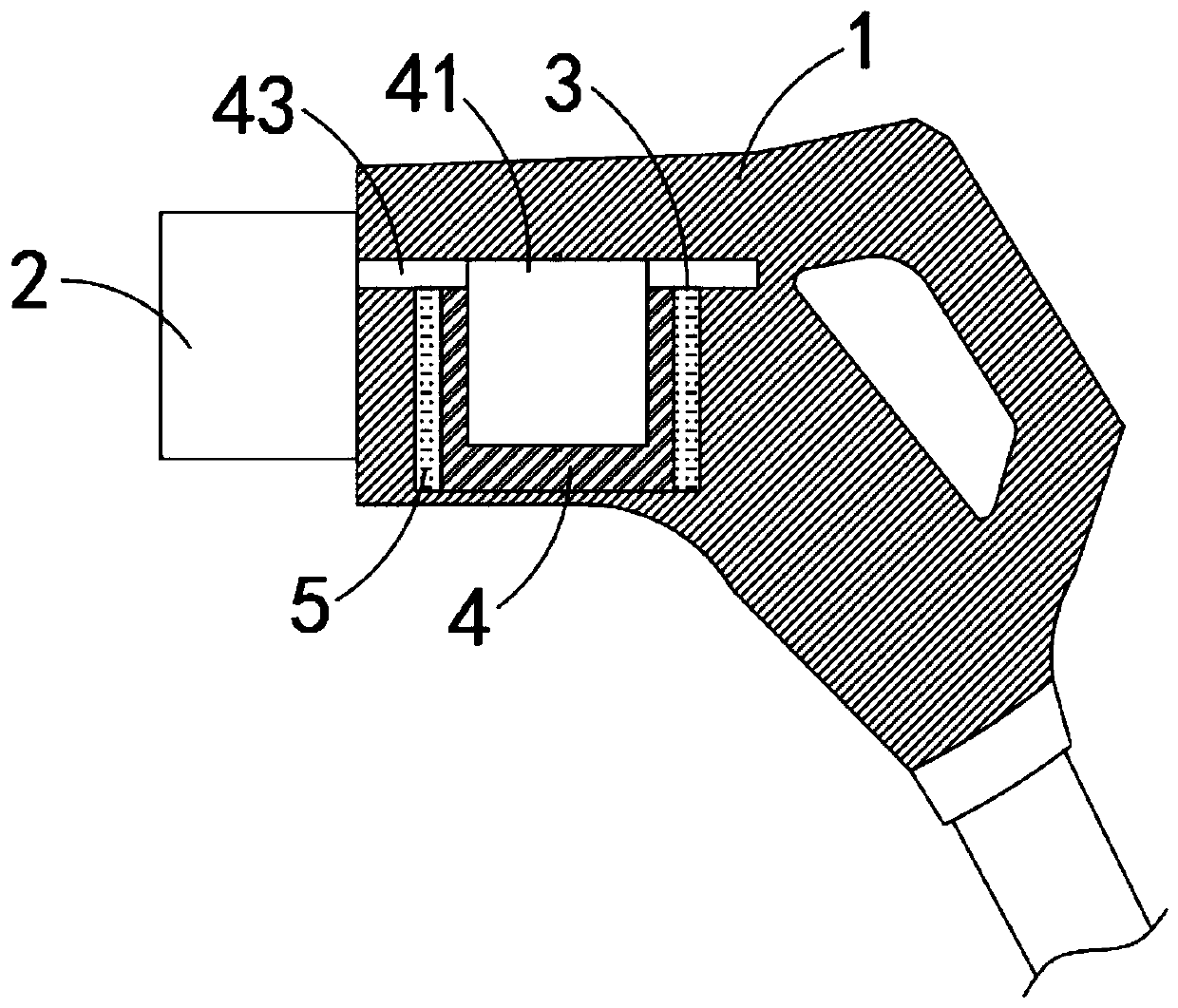

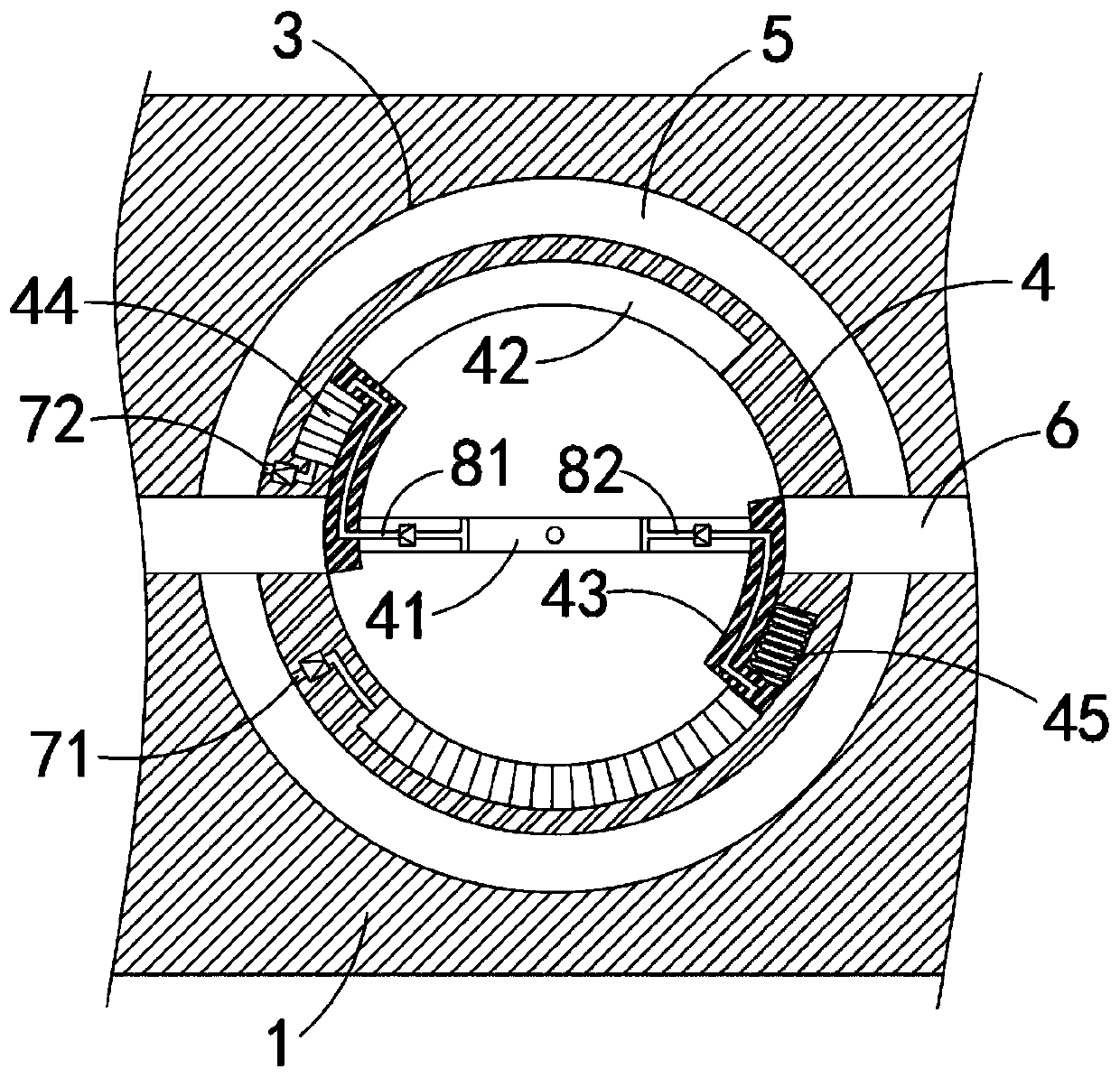

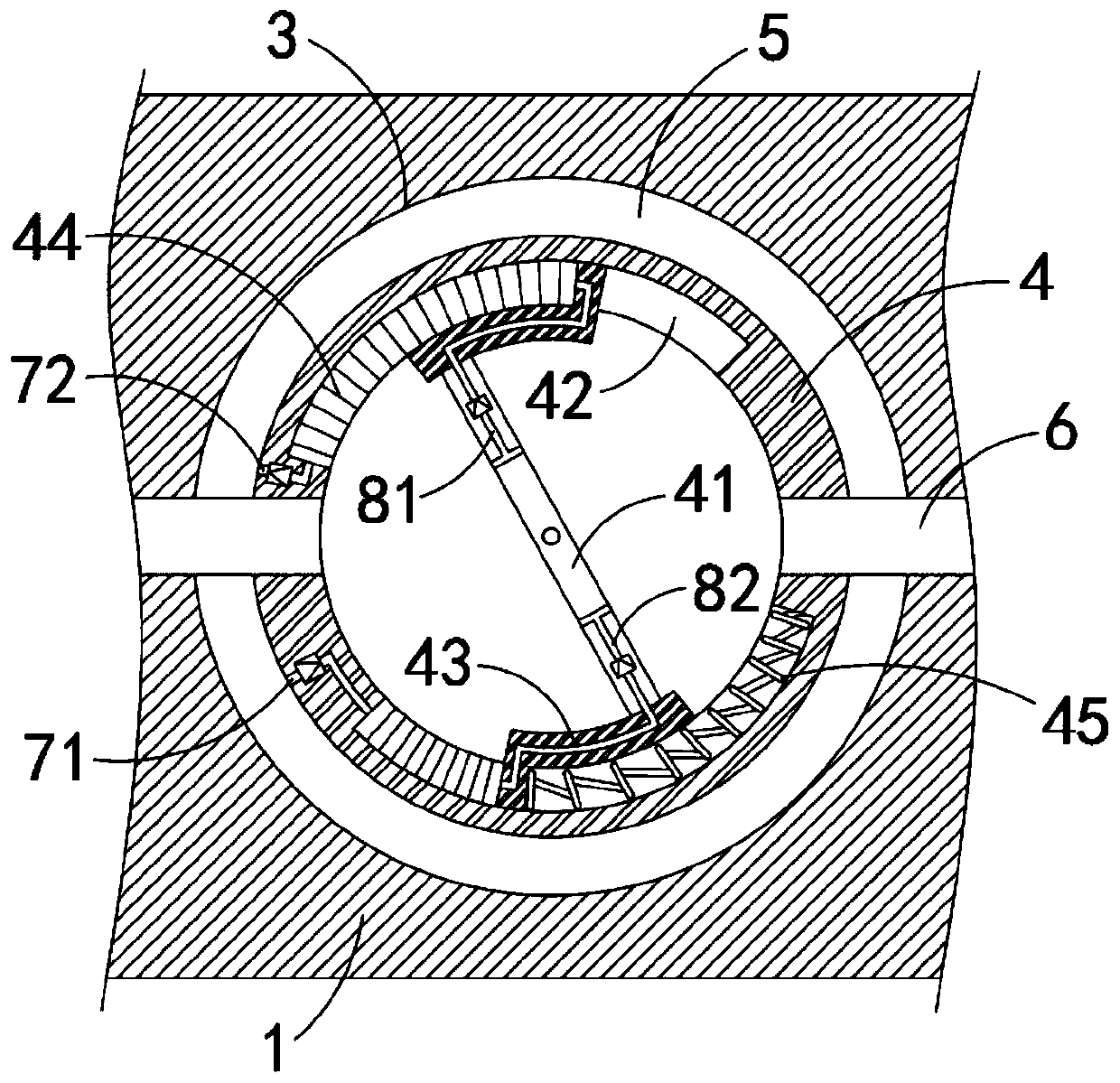

[0036] Such as Figure 1-3 As shown, a charging gun for a new energy electric vehicle includes a gun body 1, a charging head 2 is fixedly connected to the front end of the gun body 1, a cavity 3 is provided in the gun body 1, and an insulating cylinder 4 is fixedly connected to the cavity 3 , the insulating cylinder 4 can be made of insulating materials such as high temperature resistant plastics, a liquid storage chamber 5 is formed between the insulating cylinder 4 and the cavity 3, and the liquid storage chamber 5 is filled with insulating liquid, and the insulating liquid can be transformer oil, and the insulating cylinder 4 Conductive strips 6 are installed on both sides of the tube, and the two conductive strips 6 are electrically connected to the power line and the charging head 2 respectively. Inside the insulating cylinder 4 are:

[0037] Conductive plate 41, conductive plate 41 is rotatably connected with cavity 3, conductive plate 41 can rotate along the axis of ins...

Embodiment 2

[0048] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the internal conveying mechanism includes:

[0049] A one-way liquid inlet pipe 91, the input end of the one-way liquid inlet pipe 91 is connected with the inside of the insulating cylinder 4, and the output end of the one-way liquid inlet pipe 91 is connected with one of the elastic bellows 44;

[0050] One-way liquid discharge pipe 92, the output end of one-way liquid discharge pipe 92 is connected with the inside of insulating cylinder 4, and the input end of one-way liquid discharge pipe 92 is connected with another elastic bellows 44;

[0051] A plurality of circulation holes 10 are evenly distributed on the conductive plate 41 .

[0052] In this embodiment, when the conductive plate 41 rotates, the insulating liquid on both sides of the conductive plate 41 will pass through the plurality of flow holes 10 and become multiple streams, and the multiple streams impact and blen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com