Propeller and wheel paddle assembly of aircraft automobile by adopting propeller

A propeller and wheel paddle technology, applied in the field of aircraft, can solve problems such as low efficiency, weak load capacity, complex mechanism, etc., and achieve the effect of simple telescopic structure, convenient control and contraction, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

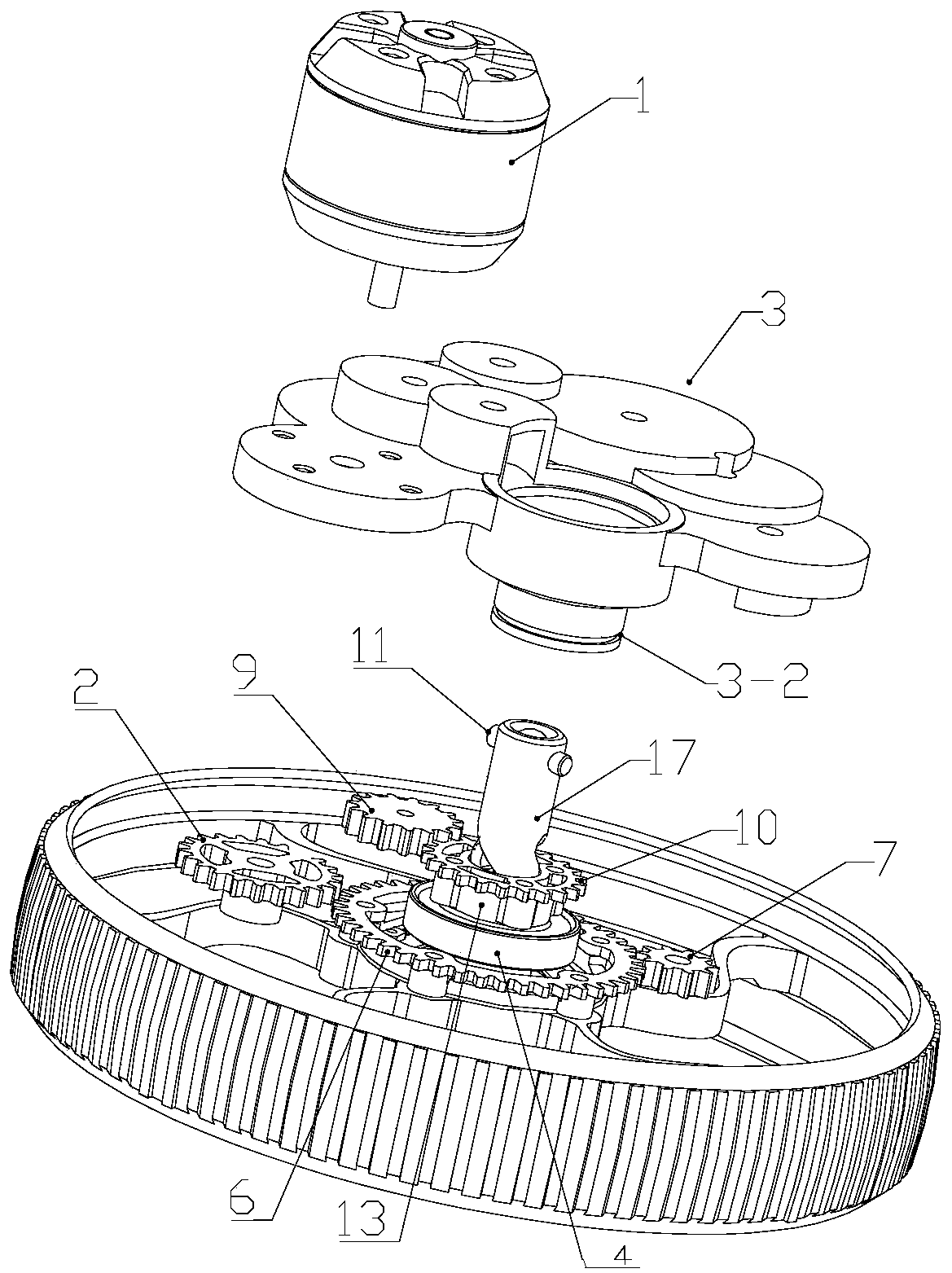

[0058] see Figure 1 to Figure 4 , a propeller, characterized in that,

[0059] Using rotating telescopic propeller;

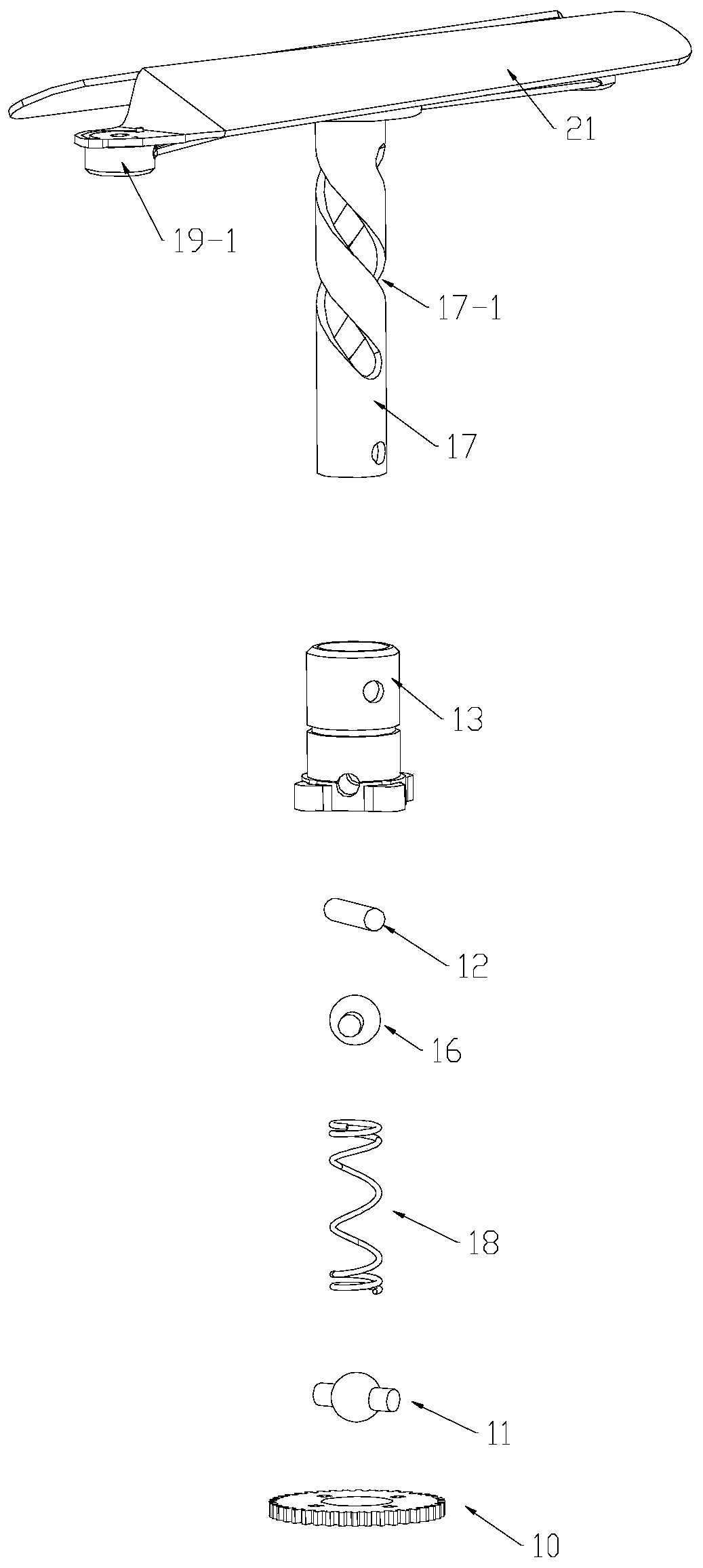

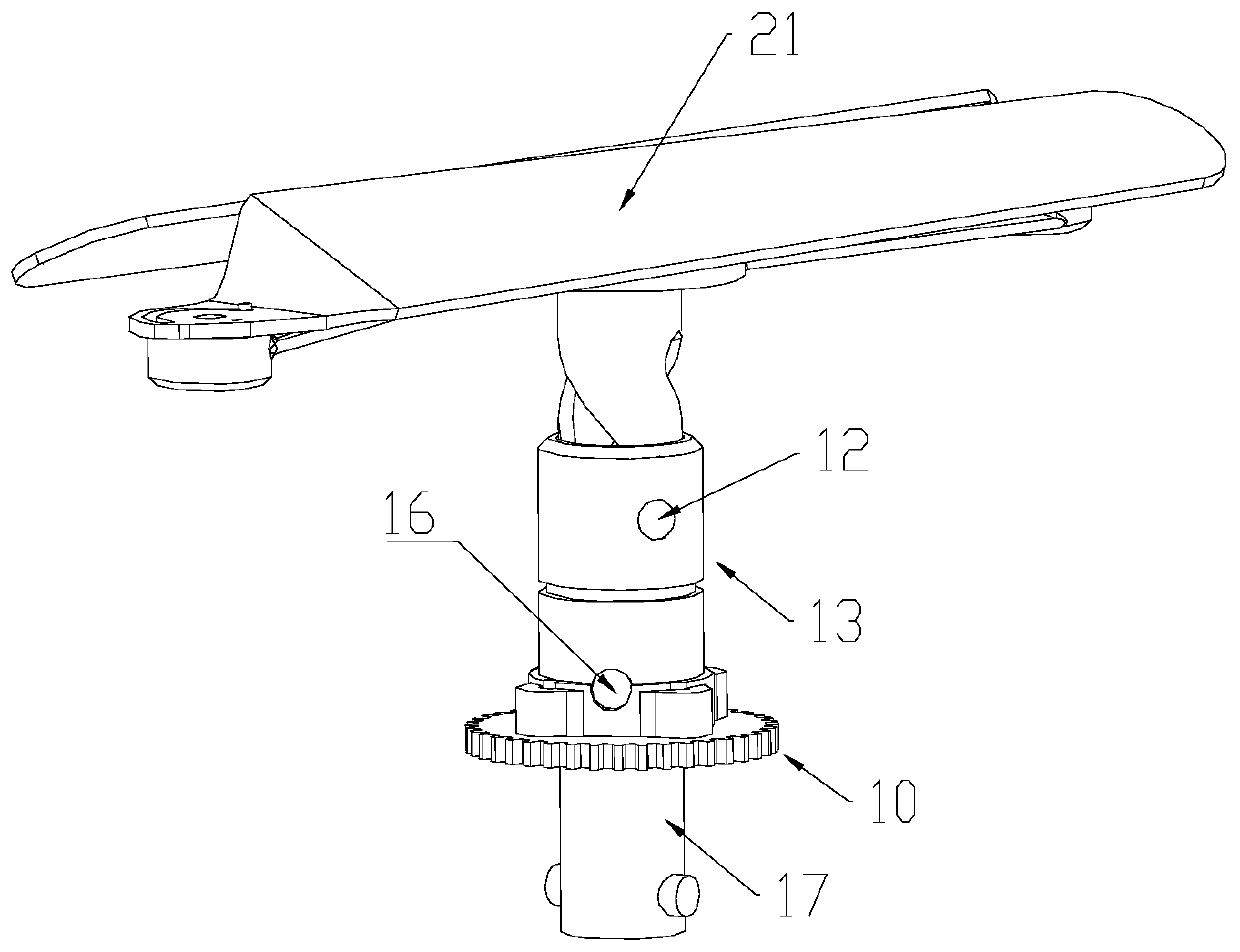

[0060] The rotary telescopic propeller includes a blade, a paddle shaft 17, a chute sleeve 13 assembled on the aircraft and driven to rotate by a drive mechanism; the top of the paddle shaft 17 is fixedly connected to the blade, and the middle part of the paddle shaft 17 The rotating and sliding sleeve is arranged in the chute sleeve 13, so that the paddle shaft 17 can rotate forward and backward relative to the chute sleeve 13; Gear 10 is assembled and connected;

[0061] Described paddle adopts foldable paddle, and described foldable paddle comprises two auxiliary paddles 19 symmetrically arranged on both sides of the top of paddle shaft 17, a main paddle 21 pinned to the outer end of auxiliary paddle 19, two The torsion springs 20 used for folding and shrinking of the propellers respectively elastically connect the auxiliary propeller 19 and the main pro...

Embodiment 2

[0069] see Figure 5 to Figure 18 , this example is the wheel propeller assembly of the aircraft automobile that adopts the propeller described in embodiment 1, comprises the wheel 8 that the center is provided with hub hole, it is characterized in that,

[0070] It also includes the propeller and the driving mechanism; the driving mechanism and the blades are respectively located on both sides of the wheel;

[0071] The upper half of the chute sleeve 13 of the propeller is pivotally connected in the hub hole;

[0072] Described driving mechanism is arranged on the wheel 8, and described driving mechanism adopts paddle-wheel switching driving mechanism, and paddle-wheel switching driving mechanism comprises: motor 1, the motor gear 2 that shaft is connected on the motor output shaft, wheel-paddle shift gear box 3. The gear plate 6 fixed on one end surface of the hub hole of the wheel corresponding to the bottom end side of the paddle shaft 17, and the wheel output gear 7 mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com