Clothes drying equipment and clothes tangling detection method thereof

A technology for clothes drying equipment and a detection method, which is applied in the field of clothing entanglement detection for clothes drying equipment and clothes drying equipment, and can solve problems such as increased wear and tear of clothes, aggravation of clothes, waste of power resources, etc. Solve the effect of clothing wear and tear, and the judgment method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a method for detecting clothes entanglement in a drying equipment. The drying equipment described in this embodiment includes a washing machine or a clothes dryer. The humidity detection device of the controller, the clothes will collide with the humidity detection device during the rotation of the drying drum, and the humidity of the clothes can be detected through the contact detection method.

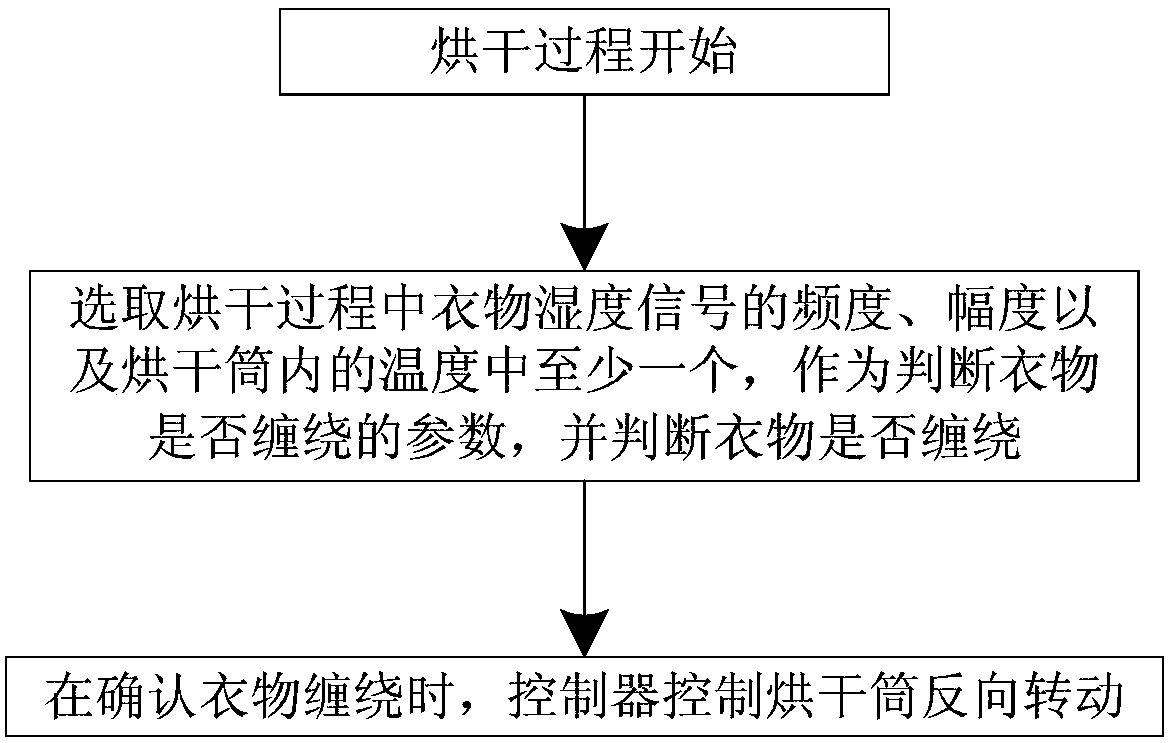

[0044] figure 1 It is a flow chart of the clothes detection method described in this embodiment. The clothes entanglement detection method described in this embodiment includes the following steps: selecting at least One is used as a parameter for judging whether the clothes are entangled, and it is judged whether the clothes are entangled; when it is confirmed that the clothes are entangled, the controller controls the drying cylinder to rotate in reverse.

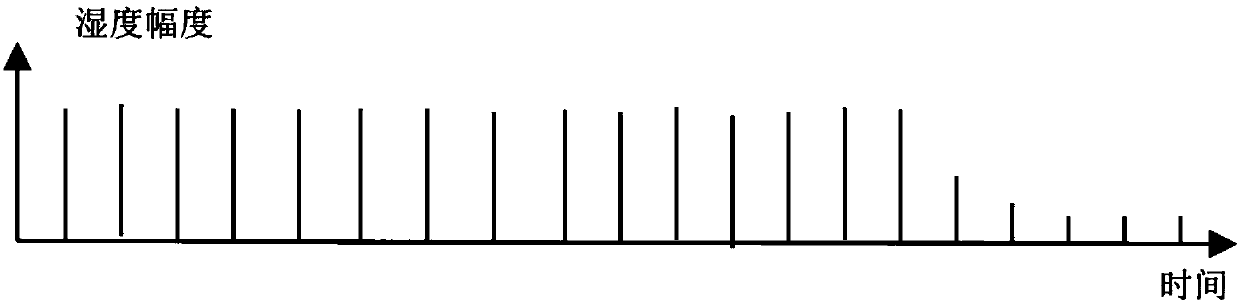

[0045] Through many tests, it is concluded that the drying time is related to the humidity ra...

Embodiment 2

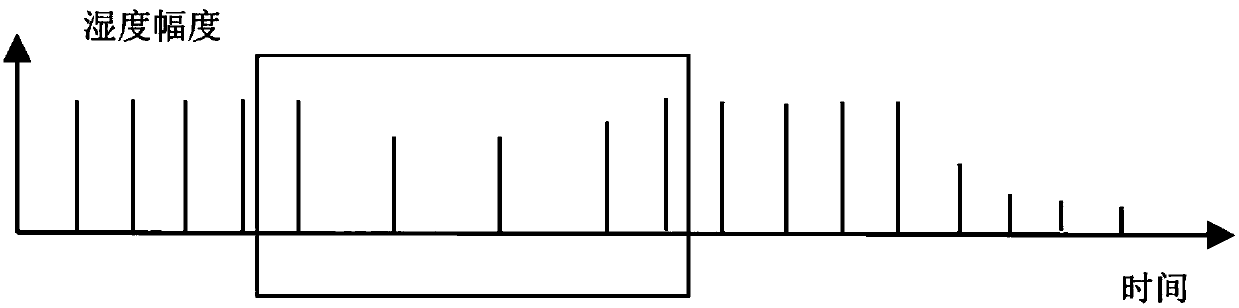

[0052] This embodiment is further improved on the basis of the first embodiment. In this embodiment, both the humidity frequency and the humidity range of the clothes in the drying drum during the drying process are used as parameters for judging whether the clothes are entangled.

[0053] Figure 6 It is a flow chart of the clothes winding detection method described in this embodiment, combined below Figure 6 The method is described in detail by using two parameters of humidity frequency and humidity amplitude as the parameters for judging whether the clothes are entangled. The clothes drying equipment described in this embodiment is a tumble dryer, and the clothes winding detection method mainly includes the following steps:

[0054] Step 1. Obtain the equilibrium temperature.

[0055] The tumble dryer is provided with a temperature detection device connected to the controller of the tumble dryer, and the temperature detection device detects the temperature in the drying...

Embodiment 3

[0071] This embodiment is further improved on the basis of the second embodiment. In this embodiment, the temperature is added as a parameter for judging whether the clothes are entangled, and the humidity frequency, humidity range and temperature of the clothes in the drying drum during the drying process are used as parameters for judging whether the clothes are entangled.

[0072] Figure 8 It is a flow chart of the clothes winding detection method described in this embodiment, combined below Figure 8 The method is described in detail by using the humidity frequency, humidity range and temperature as parameters for judging whether the clothes are entangled. The clothes drying equipment described in this embodiment is a tumble dryer, and the clothes winding detection method mainly includes the following steps:

[0073] Step 1. Obtain the equilibrium temperature.

[0074] Step 2, acquiring a preset frequency and a preset range.

[0075] Step 3. Determine whether the rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com