Patents

Literature

56results about How to "Solve wasted energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

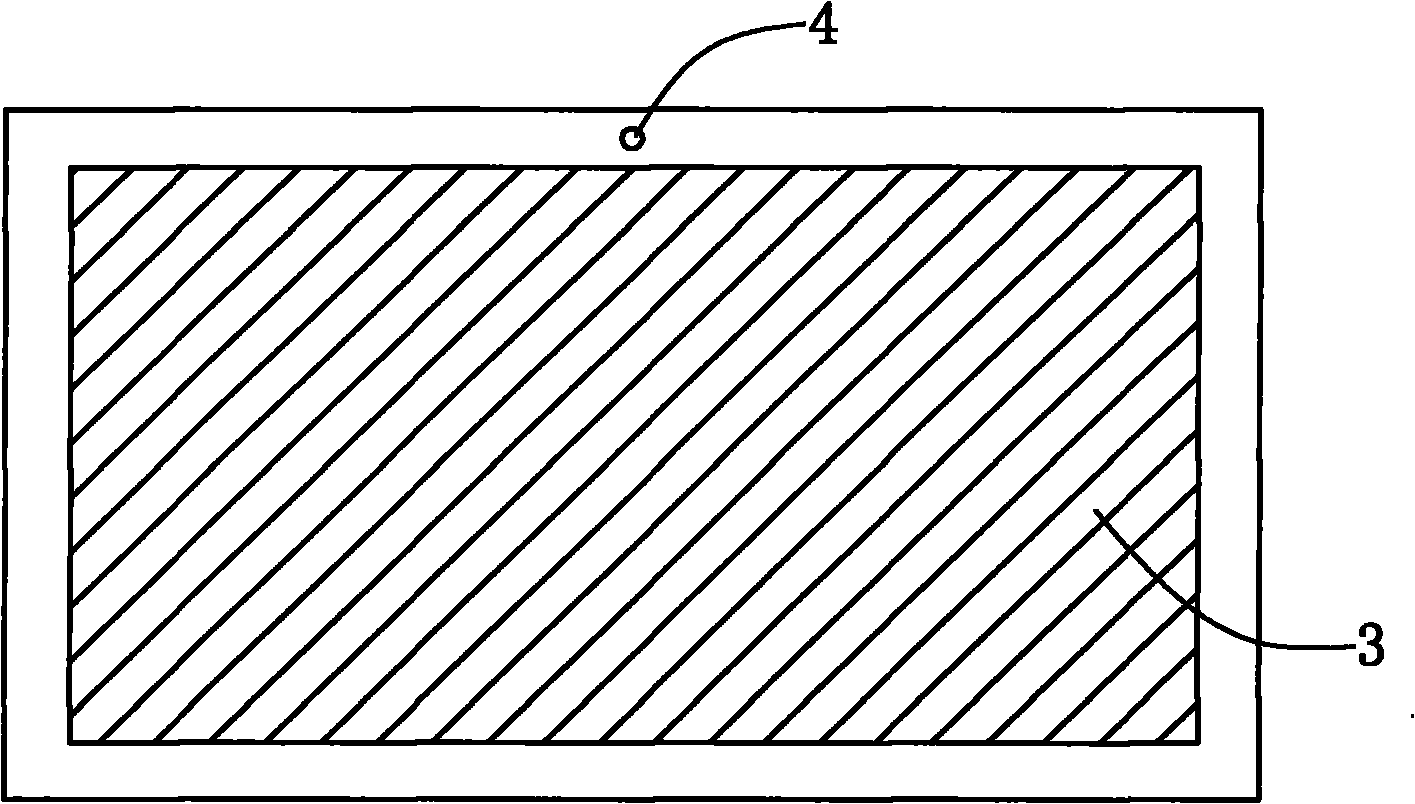

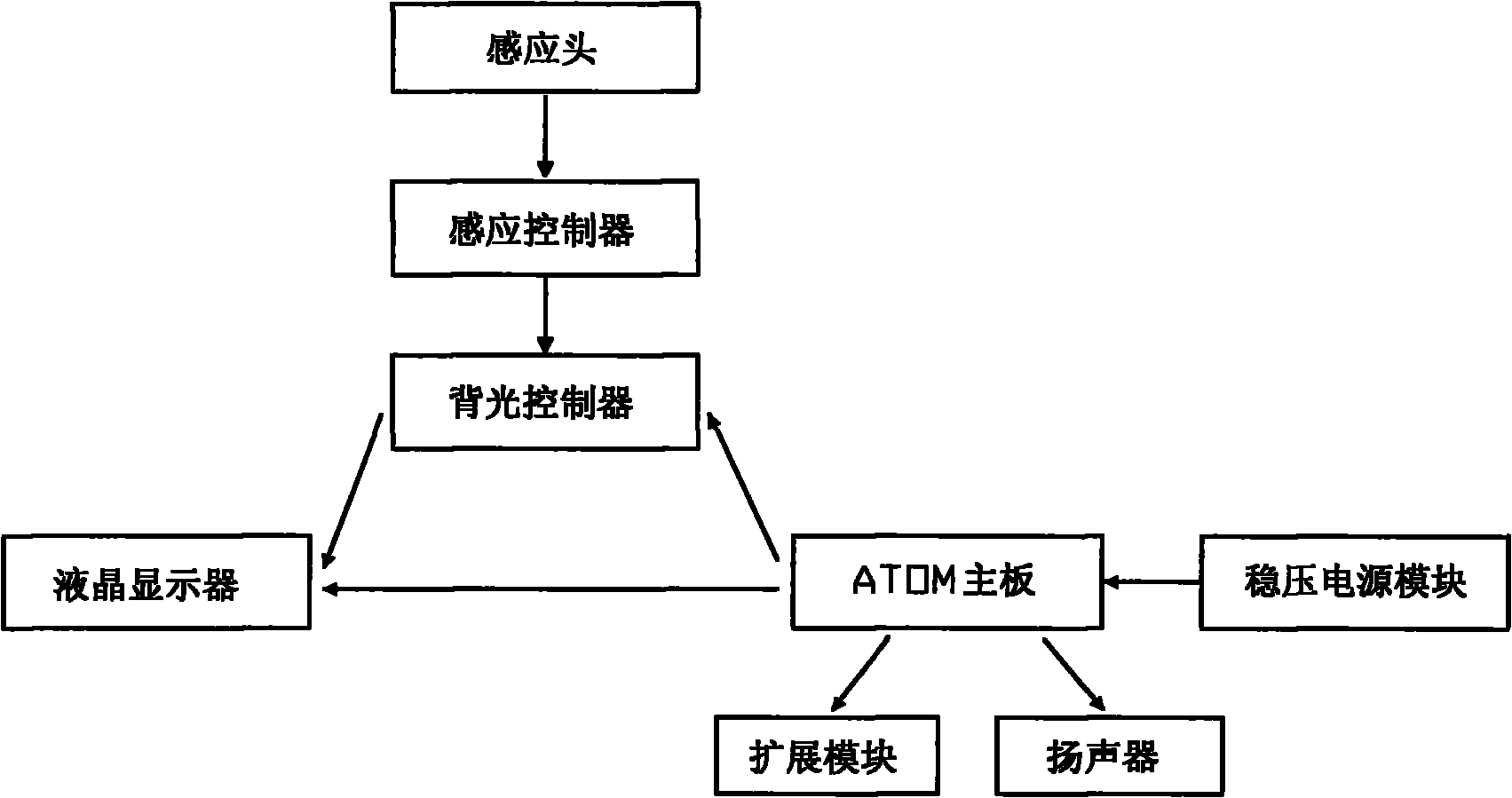

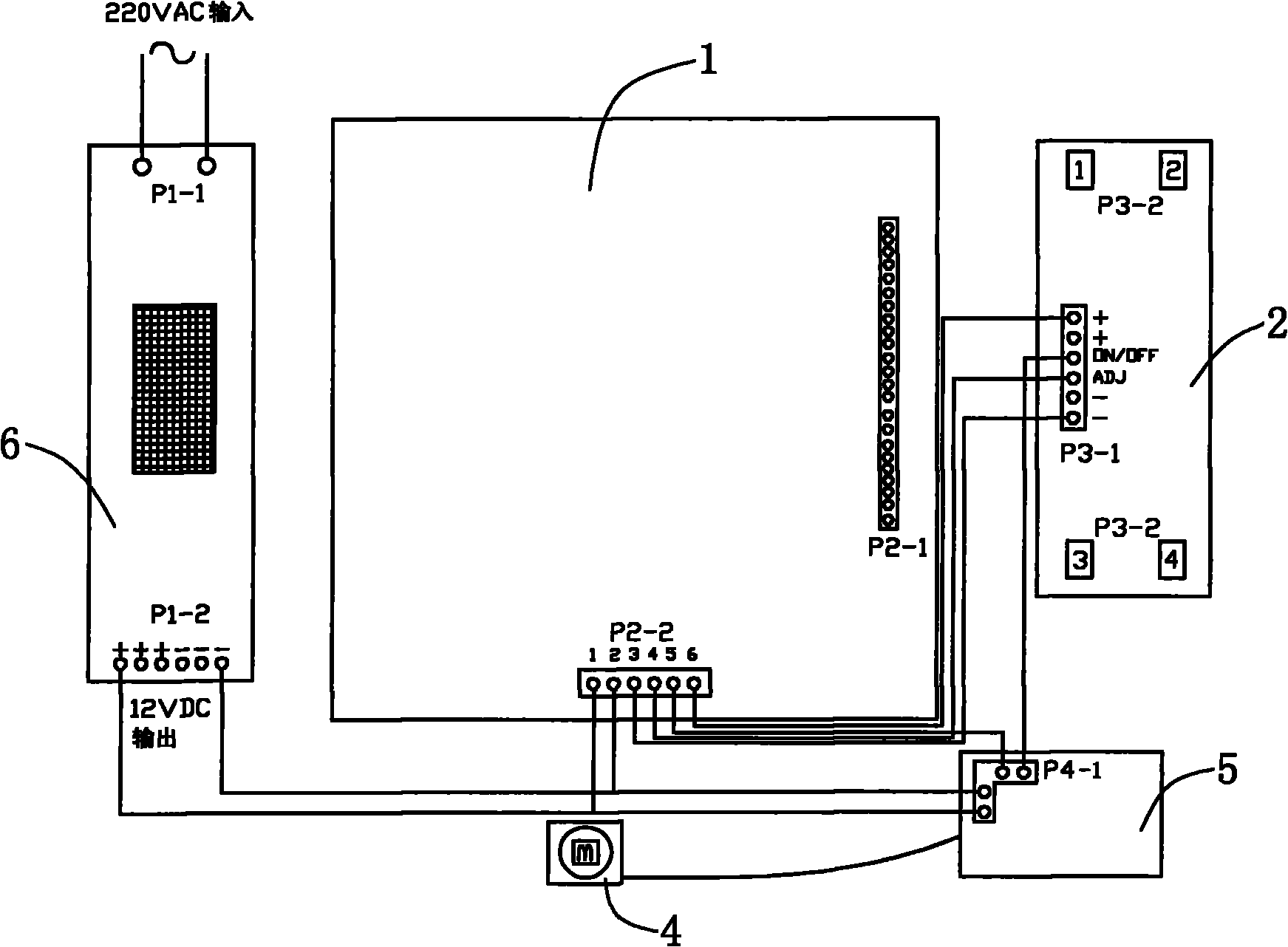

Information release terminal device with human body-sensing display

InactiveCN101930704AEasy to integrateDoes not cause frequent switchingStatic indicating devicesOptical detectionHuman bodyLiquid-crystal display

The invention discloses an information release terminal device with a human body-sensing display, which comprises a liquid crystal display and a control module, wherein the liquid crystal display is provided with a sensor for sensing a human body approaching, the sensor sends sensing signals for indicating the human body approaching to the control module, and the control module controls the back light on-off action of the liquid crystal display after receiving the sensing signals sent by the sensor. By using the infrared human body-sensing technology, the back light lamp of the liquid crystal display of an information release terminal can automatically lights when a human body approaches to an area with a radius of 3-8 meters, and the back light lamp can is delayed 1-5 minutes after the human body is away from the area. The invention has the advantages of simple structure and convenient operation, and can effectively reduce energy waste and prolong life of products.

Owner:宋四海

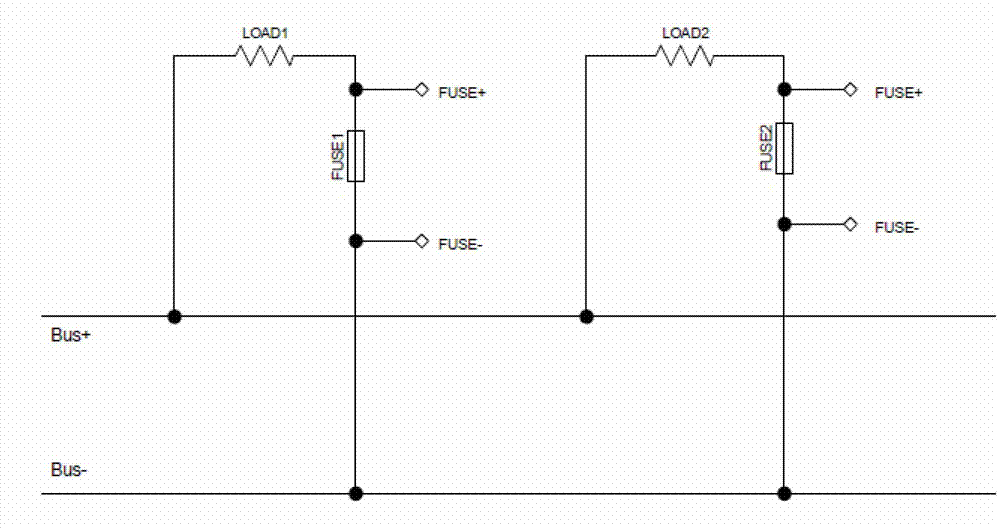

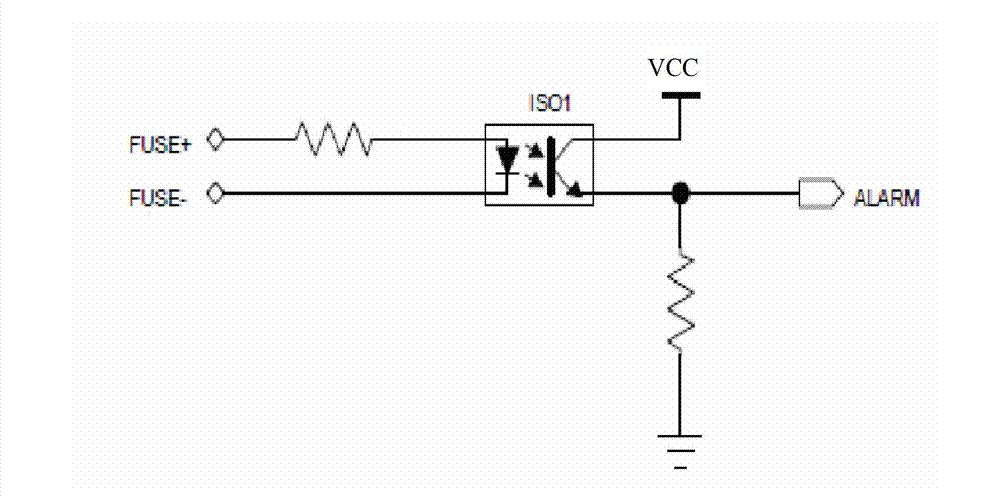

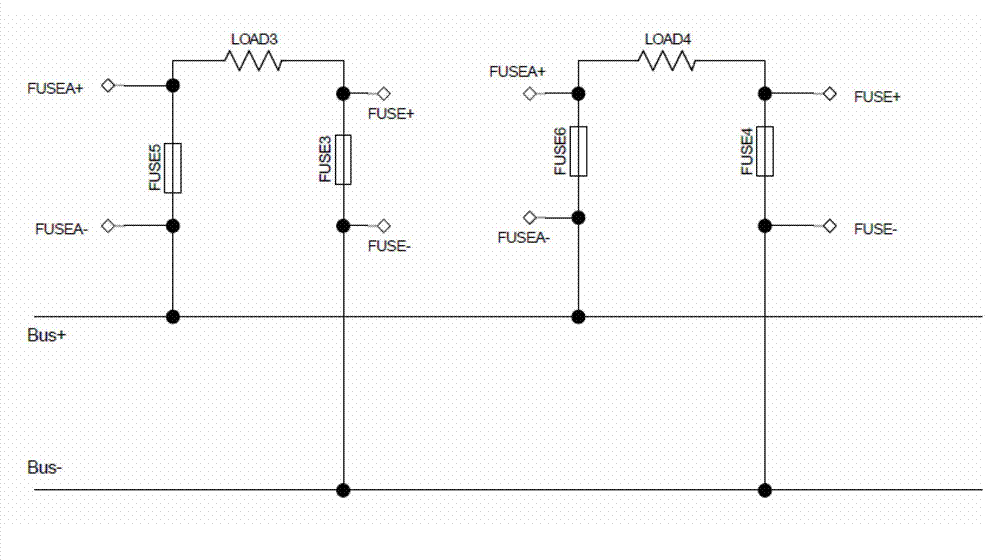

Load fuse wire detecting device and power system

ActiveCN103197189ASolve poor compatibilitySolve wasted energyFuses testingEmergency protective arrangements for automatic disconnectionElectrical and Electronics engineeringEngineering

The invention relates to a load fuse wire detecting device and a power system. The load fuse wire detecting device comprises a fuse wire state detecting module and an alarming module. The fuse wire state detecting module comprises a state detecting unit and an auxiliary power supply, the state detecting unit is used for detecting whether a corresponding fuse wire is disconnected or not, and the auxiliary power supply is used for guaranteeing the state detecting unit to work normally when the corresponding fuse wire is not disconnected. The alarming module is used for sending alarming signals according to the detecting result of the state detecting unit. The invention further relates to the power system. The fuse wire detecting device and the power system enable the compatibility of the fuse wire detecting device to be strong and improve the using efficiency of the power system through the arrangement of the state detecting unit and the auxiliary power supply.

Owner:ANHUI DYNAMIC POWER

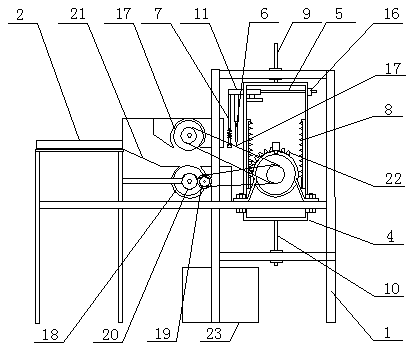

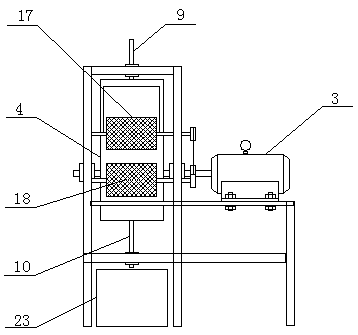

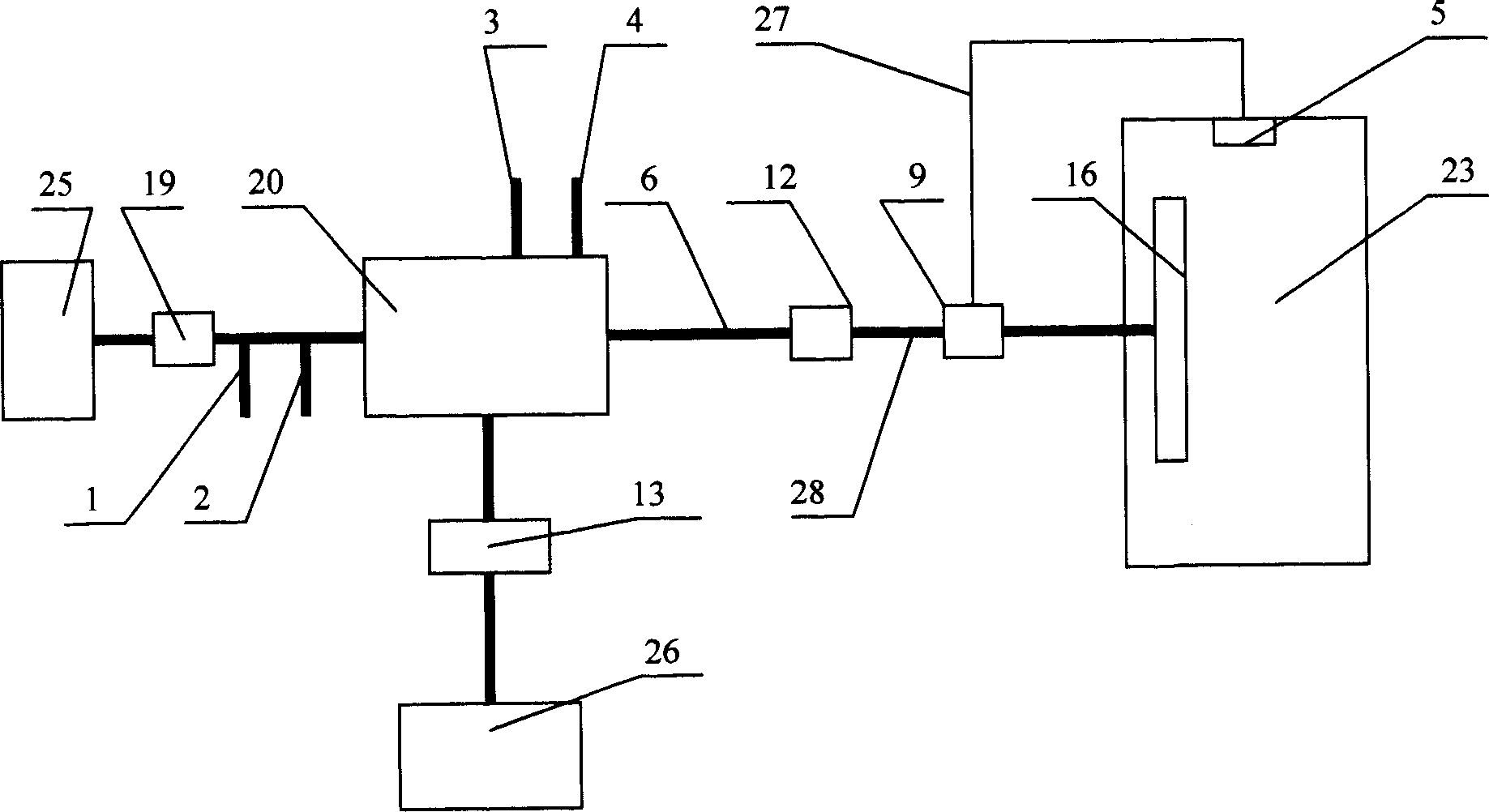

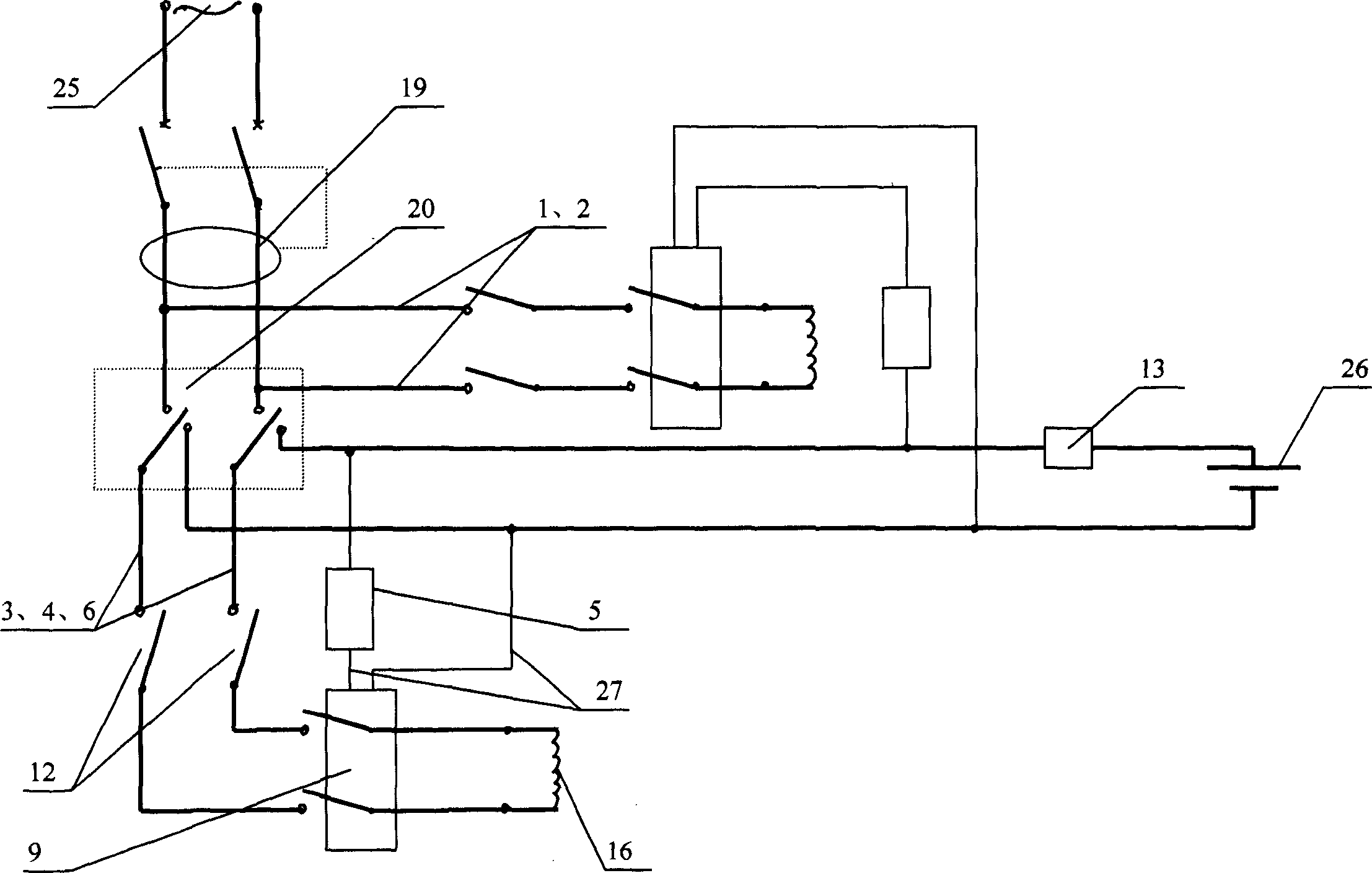

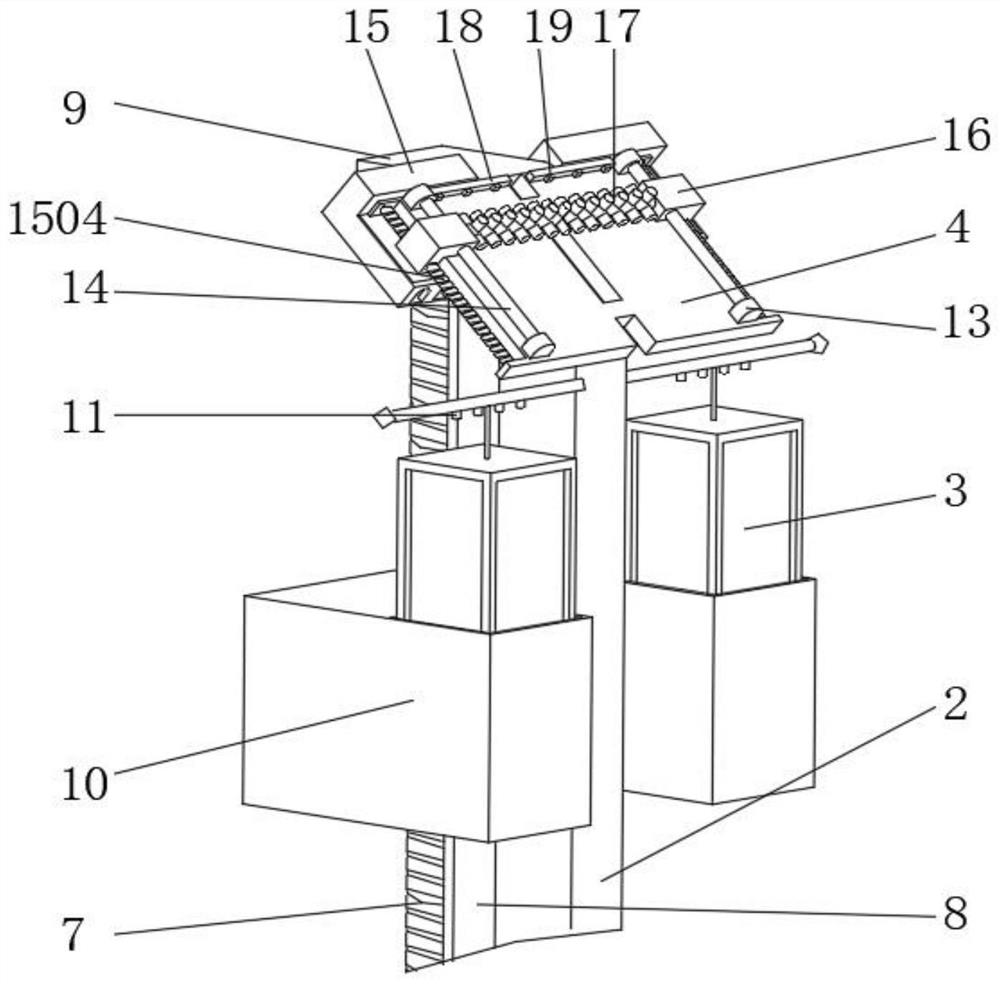

Vegetable cutter

InactiveCN109049043ASimple structureSmooth feedingMetal working apparatusVegetable processingIndustrial engineering

The invention relates to vegetable processing equipment, in particular to a vegetable cutter. The vegetable cutting machine is composed of a machine frame, a knife rest, a vegetable bearing table anda motor, wherein the knife rest is movably arranged on the machine frame, a conveying pair roll is arranged on one side of the knife rest, the vegetable bearing table is arranged on one side of the conveying pair roll, a feeding inclined plate is arranged between the conveying pair roll and the vegetable bearing table, and the motor is fixedly arranged on the machine frame corresponding to the knife rest; the motor is connected with the conveying pair roller through a transmission belt, the motor is connected with the knife rest through an incomplete gear, and a collecting basket is arranged below the machine frame corresponding to the knife rest. The vegetable cutter is simple in structure, the working state of the cutter is similar to that of manual operation, disassembly and cleaning are easy, feeding of the conveying pair roll are stable, all power of the vegetable cutter machine is supplied by one motor, energy is saved, the problem that an existing vegetable cutter is complex instructure, the vegetables are easily accumulated and the energy is wasted are solved, and the requirements of the food processing industry are met.

Owner:YANGTZE UNIVERSITY

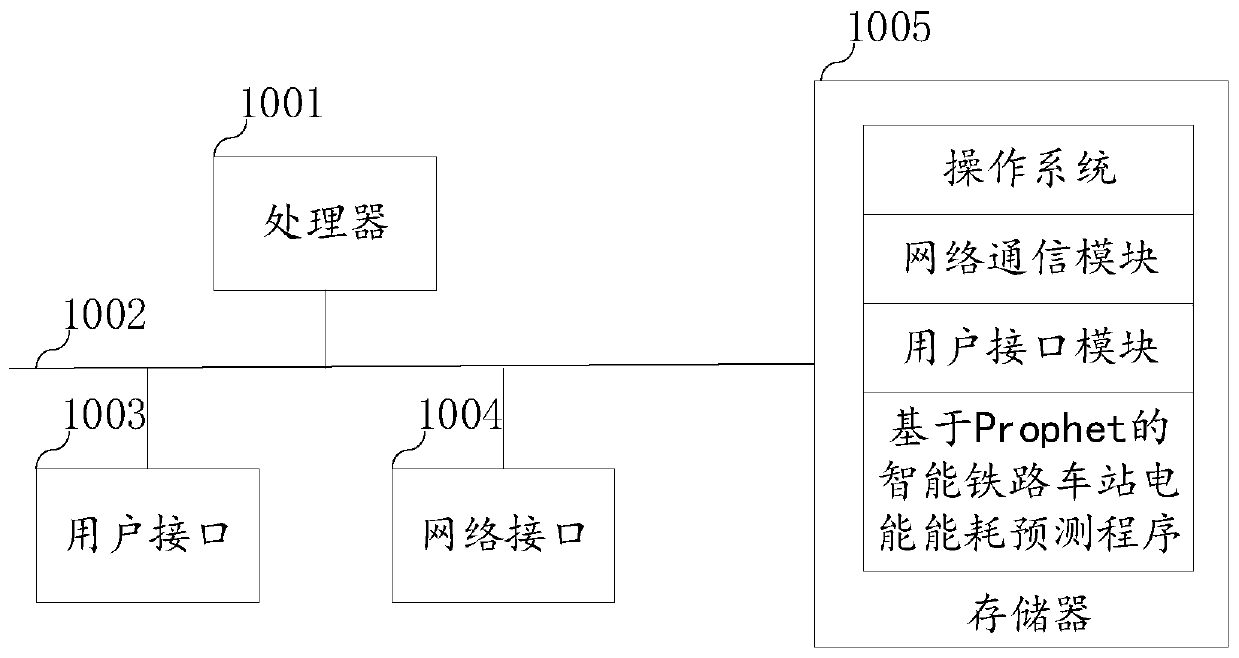

Intelligent railway station electric energy consumption prediction method based on Prophet

The invention belongs to the technical field of energy consumption prediction, and discloses an intelligent railway station electric energy consumption prediction method based on Prophet. The method comprises the following steps: monitoring each sub-node in a power utilization system to obtain actually measured electric energy consumption data corresponding to each sub-node; and inputting the actually measured electric energy consumption data corresponding to each sub-node into a preset prediction model to obtain a prediction curve graph corresponding to the predicted electric energy consumption data. Through the above mode, the to-be-tested electric meter is effectively predicted so as to search a high energy consumption link, and then a technical means is adopted to achieve an effect ofsaving energy.

Owner:HUBEI KAIMEI ENERGY TECH

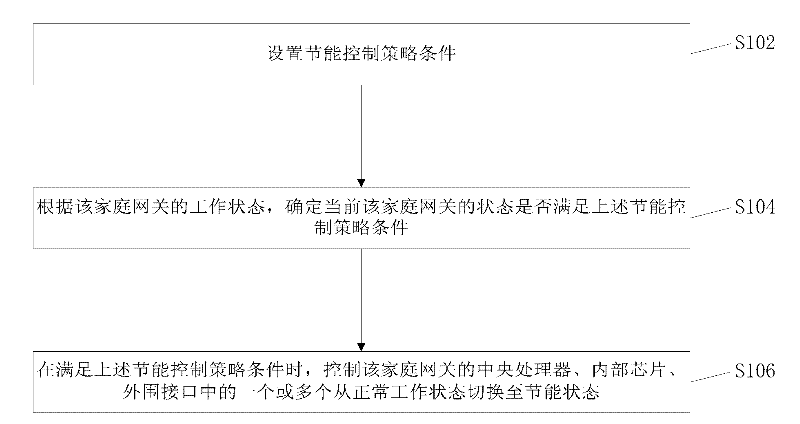

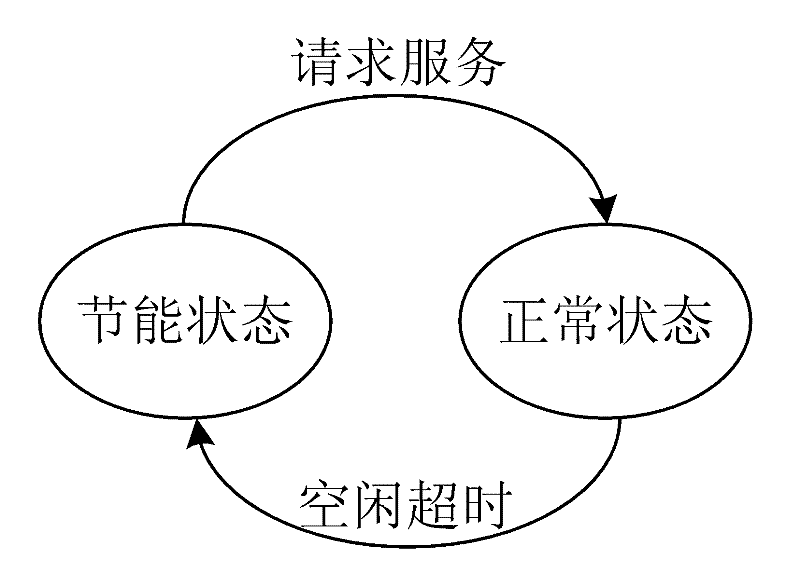

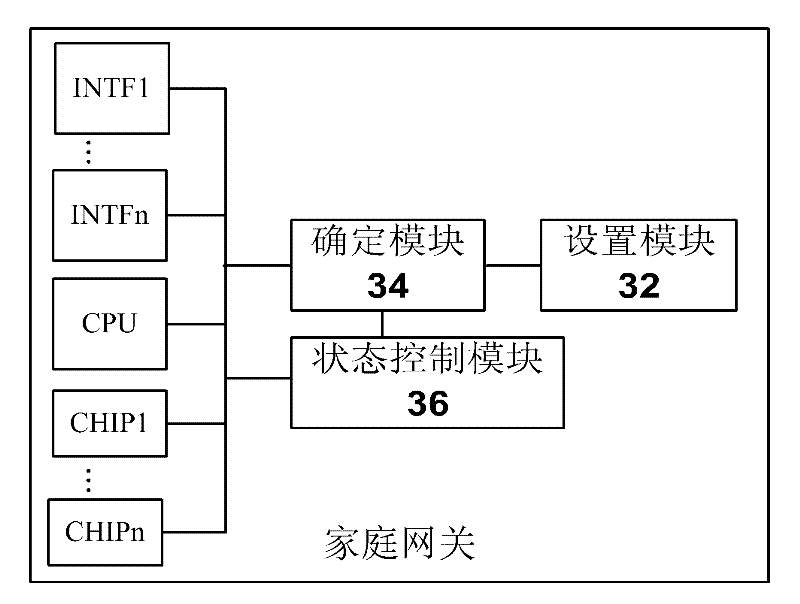

Home gateway energy saving method and home gateway

InactiveCN102480398ADoes not affect experienceSolve wasted energyData switching by path configurationNetwork connectionsWork statusEngineering

The invention discloses a home gateway energy saving method and a home gateway. The home gateway energy saving method comprises the following steps of: setting an energy saving control strategy condition; determining whether the home gateway can meet the energy saving control strategy condition according to a working state of the home gateway; and if the home gateway meets the energy saving control strategy condition, controlling one or more of a central processor, an internal chip and a peripheral interface in the home gateway to be switched from a normal working state to an energy saving state. By the home gateway energy saving method, the problem of a large amount of wasted energy of the conventional home gateway equipment is solved; and on the premise that the user experience is not influenced, an effect of saving the energy to the maximum extent is achieved.

Owner:ZTE CORP

Electronic device

InactiveCN105207337AExtended use timeSolve the problem of longevityBatteries circuit arrangementsElectric powerElectricityThermal energy

The invention discloses an electronic device. The electronic device comprises a rechargeable battery; a heating device; a heat conduction film, which is arranged on the surface of the heating device and is used for conducting the heat dissipated by the heating device; at least one temperature difference power generation piece, of which the hot end is arranged at the side, away from the heating device, of the heat conduction film, and which is used for converting the heat emitted by the heating device into electric energy; and a charging control circuit, which is electrically connected with the temperature difference power generation piece and the rechargeable battery, and is used for controlling the process of charging the rechargeable battery by utilizing the electric energy generated by the temperature difference power generation piece. According to the electronic device, the heat emitted by the component in the circuit is utilized to charge the battery, so that the problems of reducing the service life of the device and wasting energy due to the generation of a lot of heat in the working process of the electronic device are solved, and service time of the battery is increased under the condition of having no external power supply.

Owner:KUSN INFOVISION OPTOELECTRONICS

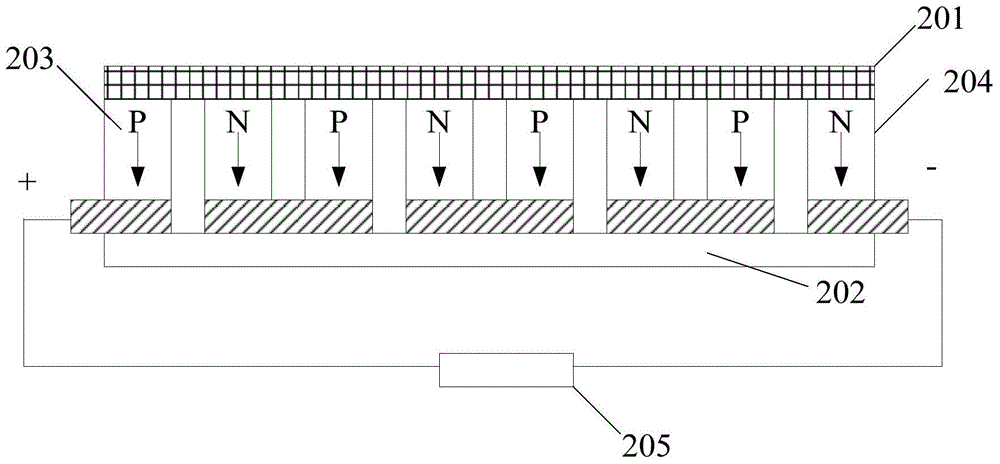

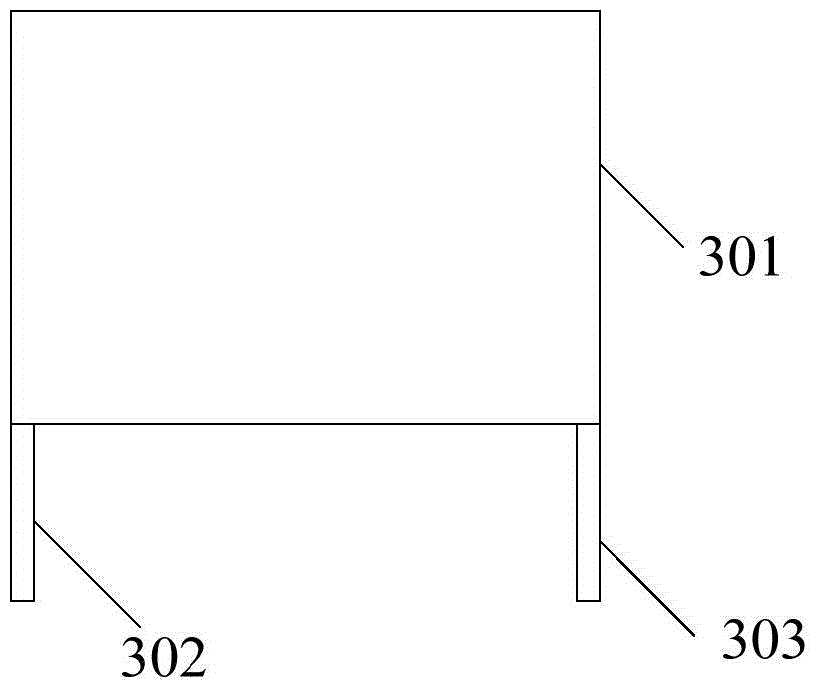

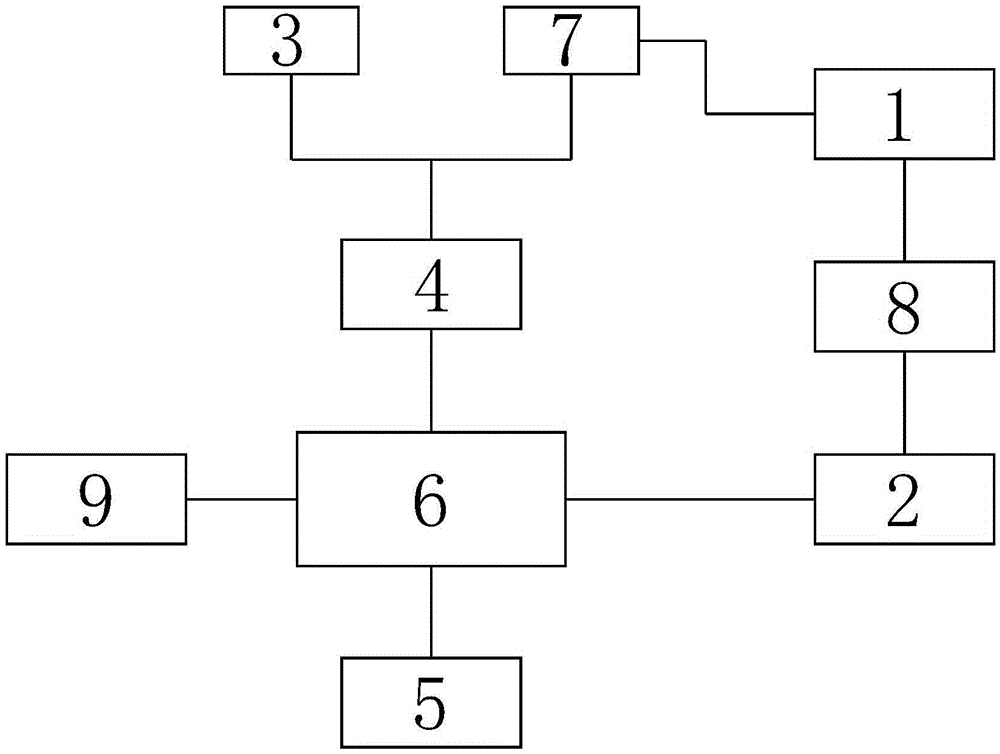

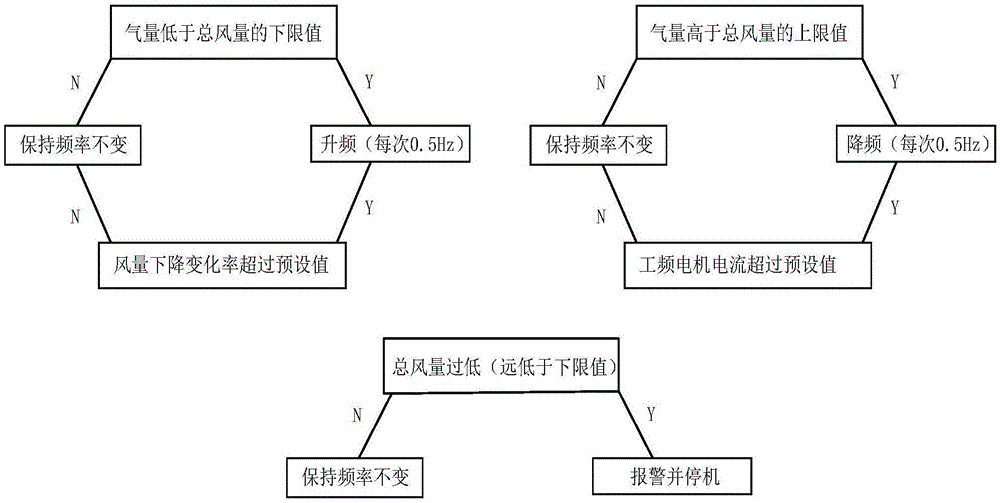

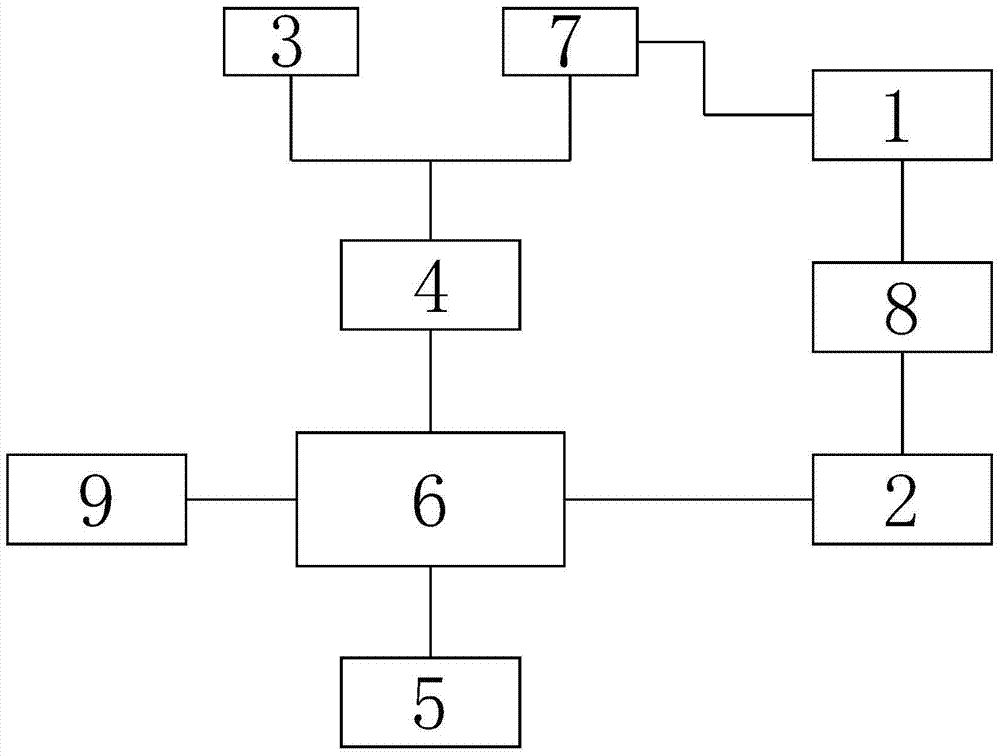

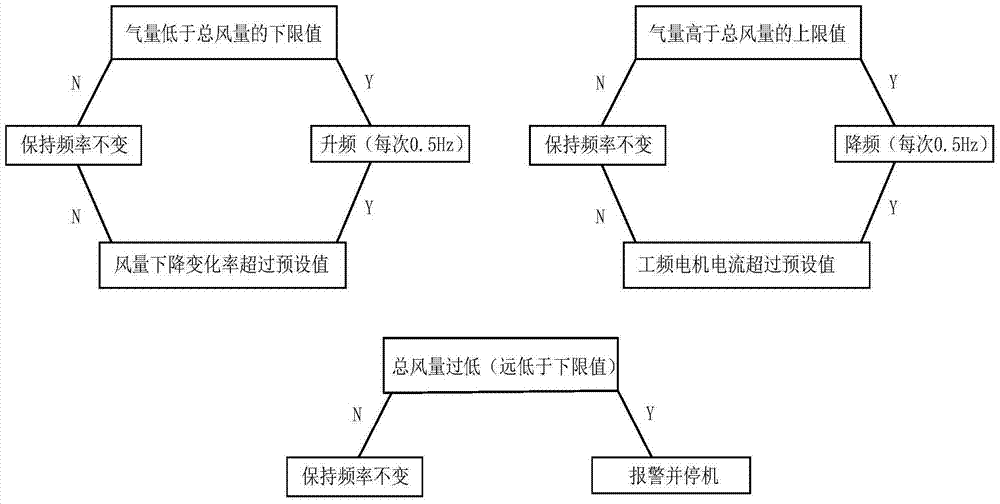

Air blower variable-frequency control device based on power frequency motor and control method for air blower variable-frequency control device

ActiveCN105465029AAvoid surge phenomenonSimple structurePump controlNon-positive displacement fluid enginesFrequency changerAir volume

The invention relates to an air blower variable-frequency control device based on a power frequency motor and a control method for the air blower variable-frequency control device. The air blower variable-frequency control device comprises the power frequency motor, a frequency converter, a controller and a communication assembly, wherein the frequency converter and the power frequency motor are connected by virtue of an electric wire, and the controller is in control connection with the frequency converter by virtue of the communication assembly; the controller comprises a storage unit, a comparison unit, an alarm unit, a PLC (programmable logic controller) control unit and a detecting unit; an electric reactor is further arranged between the frequency converter and the power frequency motor; the detecting unit is connected to the power frequency motor, and is used for feeding back a detected actually-measured frequency value and an actually-measured current value of the power frequency motor, and an outlet total air flow value of the air blower to the comparison unit. The air blower variable-frequency control device has the advantages of being simple in structure, reasonable in design, high in degree of automation, and capable of effectively reducing a calorific value of a frequency converter motor to achieve the purpose of automatically regulating to realize energy saving; and by reasonably controlling and regulating the frequency of the frequency converter, and the occurrence of a surging phenomenon of the air blower due to energy waste or too low frequency caused by too high frequency is avoided.

Owner:XIAOHONGMEN SEWAGE TREATMENT PLANT BEIJING DRAINAGE GRP

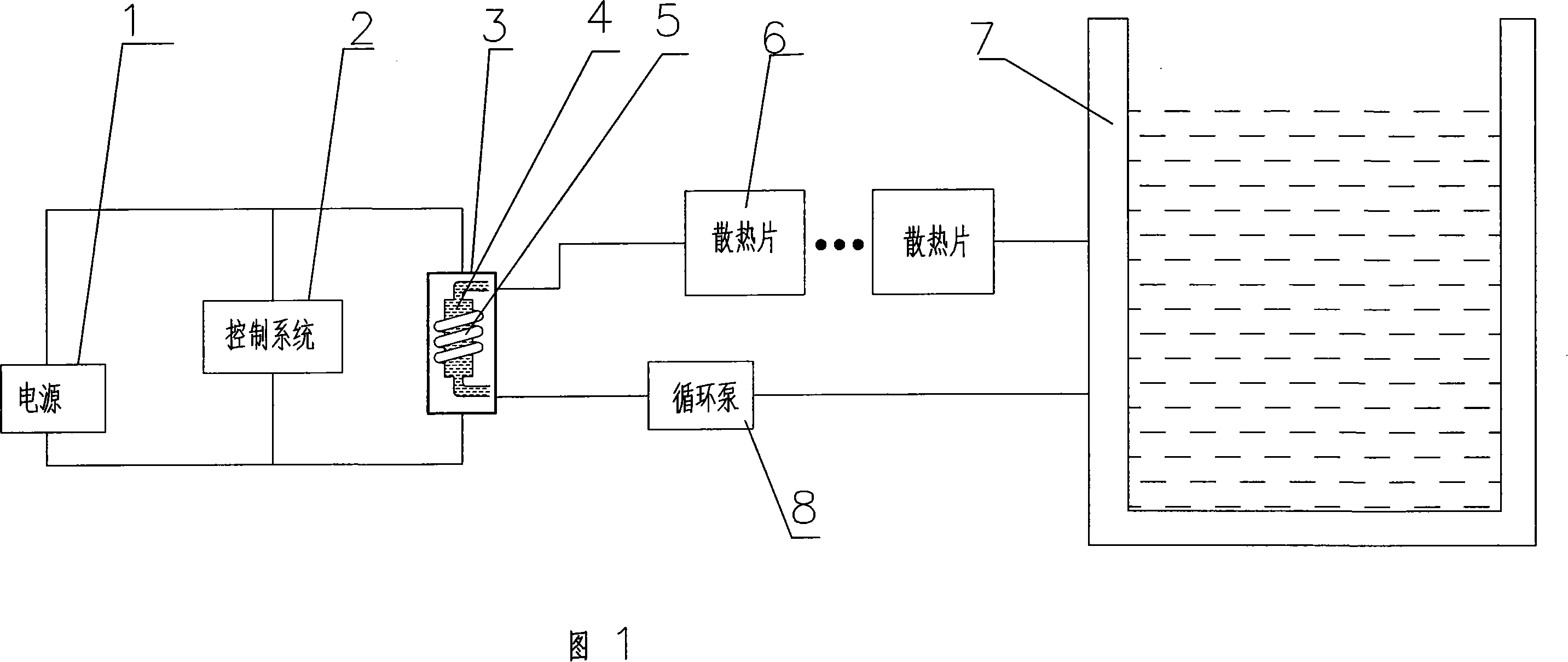

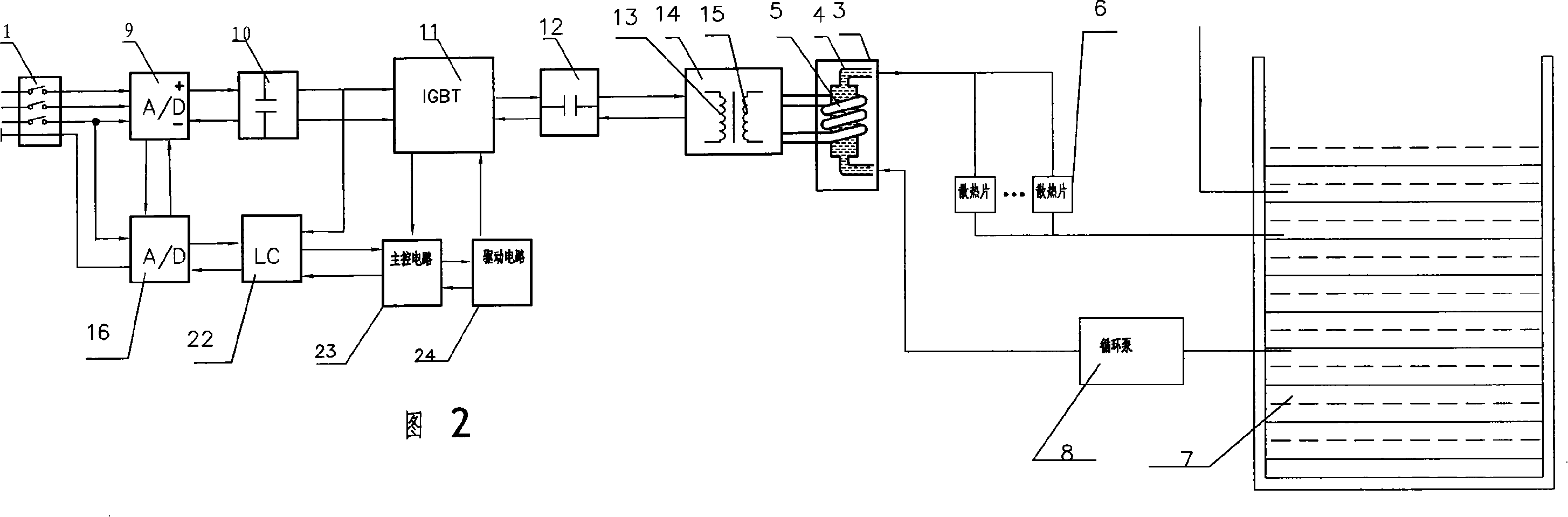

Intermediate frequency electronic heating and warming device

InactiveCN101149165ASolve the problem of polluting the environmentHeating up fastLighting and heating apparatusSpace heating and ventilation detailsHeat sinkVoltage

This invention is a heating device, especially an intermediate frequency electron heating device. It saves energy, non-polluted and intelligent controllable. It also has high thermal efficiency. It includes power source, water tank and circulating valve. Oscillating circuit, which generates intermediate frequency alternating voltage and alternating current, connects to the intermediate frequency electron heating device that generates alternating magnetic field and electromagnetic oscillation. The said oscillating circuit is controlled by controlling system. The intermediate frequency electron heating device is a magnetic metal container, with the heating coil at external part and liquid at internal part. Tandem radiating fins form the pipeline system. The water tank and circulating valve are connected to from circulating system. The intermediate frequency electron heating device, pipeline system and circulating system are connected in series to form the heating circulating loop. This invention can fulfill central heating.

Owner:齐向臣

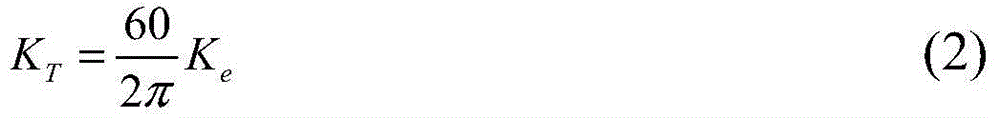

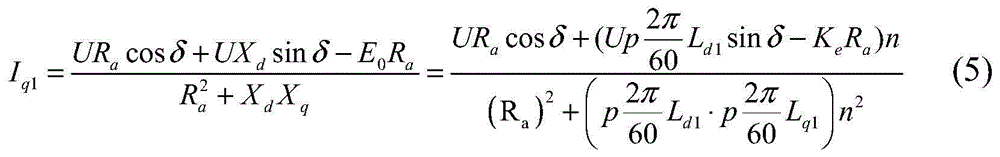

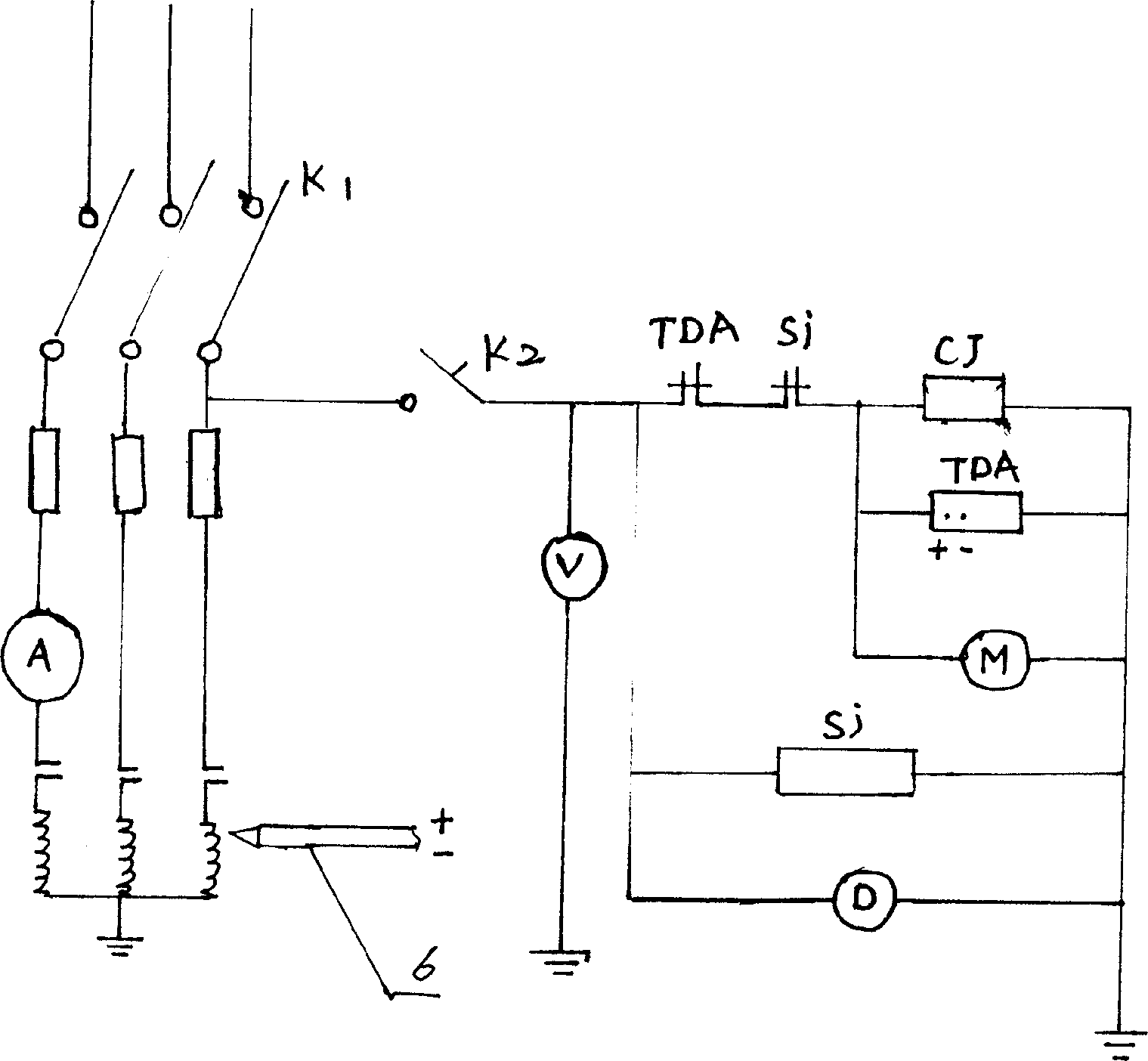

Temperature rise test method for multiphase multi-unit permanent magnet motor

ActiveCN104808148ASolve wasted energyMeet the needs of temperature rise testDynamo-electric machine testingTesting equipmentVoltage

The invention belongs to the technical field of motor testing, discloses a temperature rise test method for a multiphase multi-unit permanent magnet motor and aims to solve the problems of energy consumption in long-time operation of the motor and request of additional testing equipment in a current temperature rise testing process for a permanent magnetic synchronous motor. The method includes the steps: enabling one unit of the tested motor to be in power generation operation; enabling another unit of the tested motor to be in electric operation; measuring a power angle, a phase resistance voltage value and a current waveform of a three-phase winding; taking all units as electric units to access to a circuit, controlling a direct-axis voltage and a quadrature-axis voltage applied to the winding to enable direct-axis and quadrature-axis currents of the winding to meet test constraint conditions, and measuring a current temperature rise curve of the motor; changing a load connected to a power generation unit end to obtain temperature rise curves of the multi-unit motor under the conditions of different rotation speeds and different loads. Current parameters and output power of the motor under a loaded condition are obtained by enabling one unit of the motor to be in electric operation and another unit of the motor to be in power generation operation.

Owner:HARBIN INST OF TECH

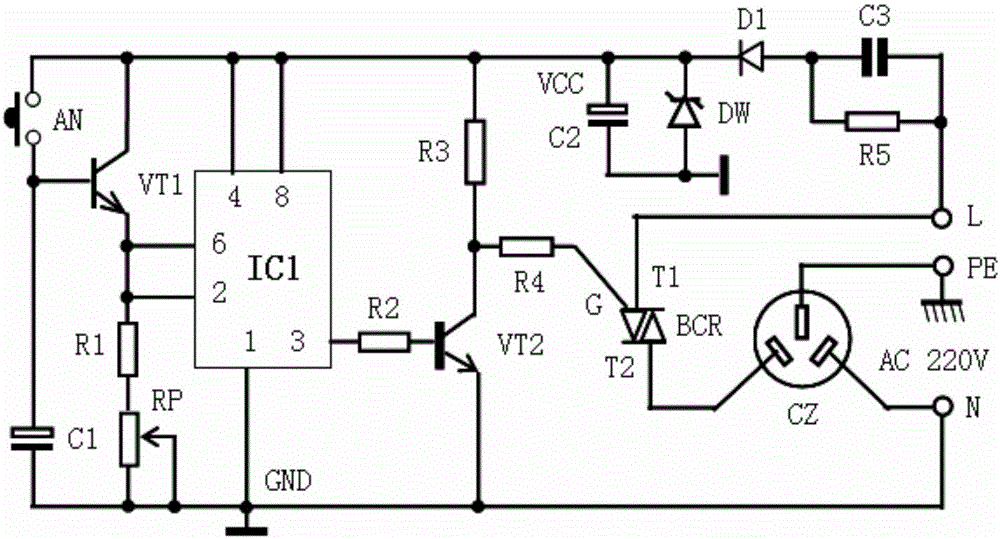

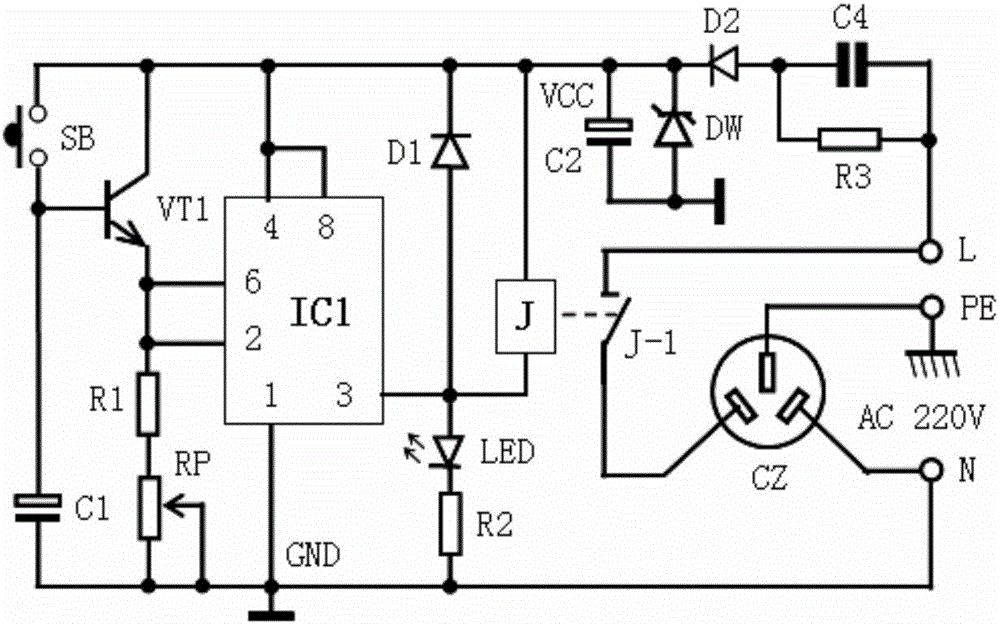

Universal-type electric cooker long-time delay power socket

InactiveCN105680253ASolve the problem of not being able to timeSolve wasted energyCoupling device detailsTime delaysVoltage regulation

The invention provides a universal-type electric cooker long-time delay power socket, which is characterized by comprising a 220V AC power supply, a long-time delay charging circuit, a monostable circuit, a level phase inversion circuit, an electric cooker power socket control circuit and a 12V half-wave rectification filtering voltage regulation power supply, wherein a time base circuit IC1 in the monostable circuit adopts a model of NE555. In view of defects existing in the universal-type electric cooker, a circuit design and a making technology for making the time delay to exceed 30 minutes by using the time base circuit are bottlenecks hard to break through; in order to effectively solve the technical problem of long time delay of the time base circuit, on the basis of the typical time base circuit time delay circuit, several common elements are only added to the time delay circuit, and thus, the requirement for making a long-time delay circuit is realized. The problems that the universal-type electric cooker can not be timed and energy is wasted by continuous heating after the universal-type electric cooker is energized are solved, and the purposes of safety use and saved power of the electric cooker are achieved.

Owner:周芸

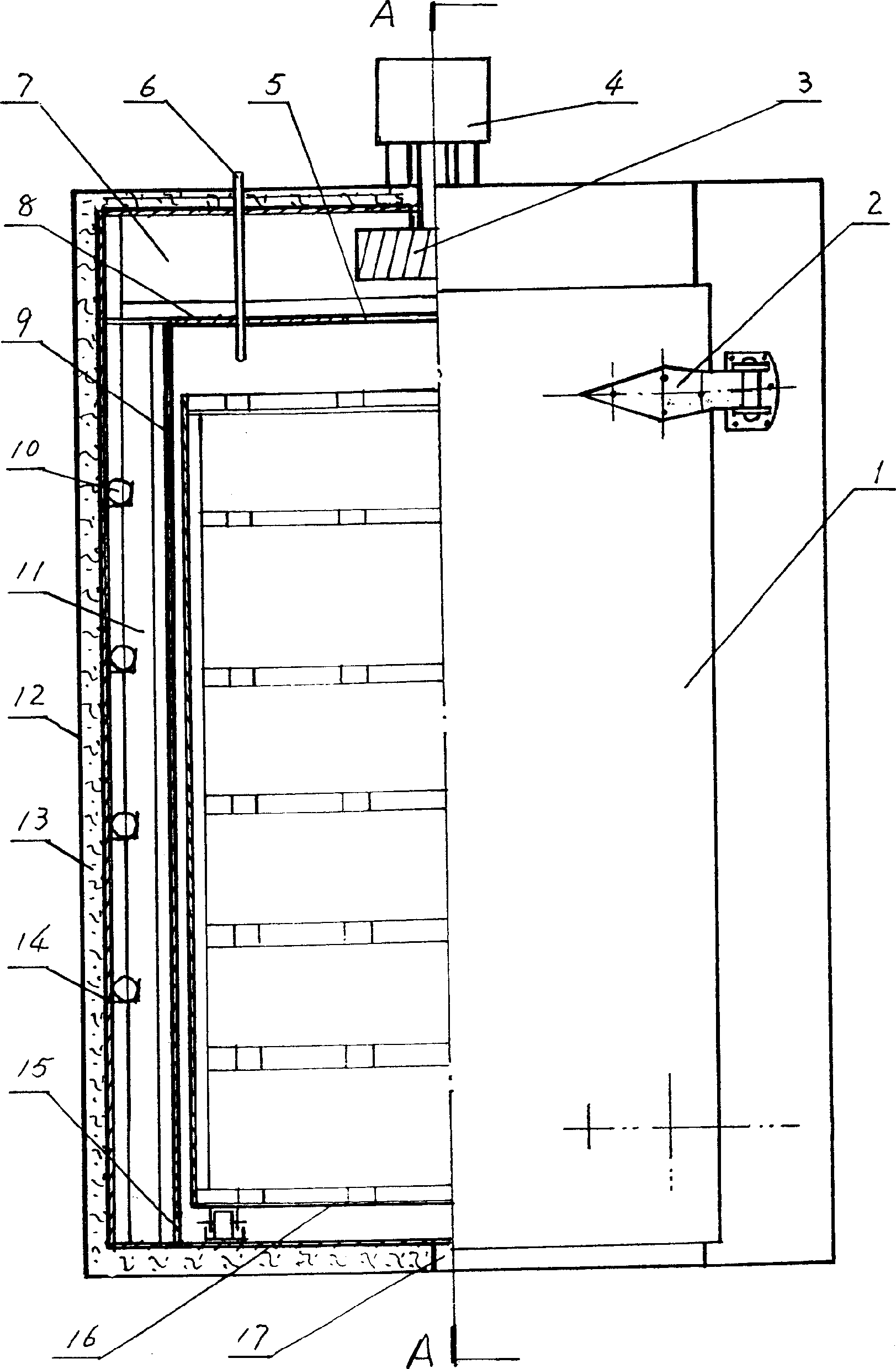

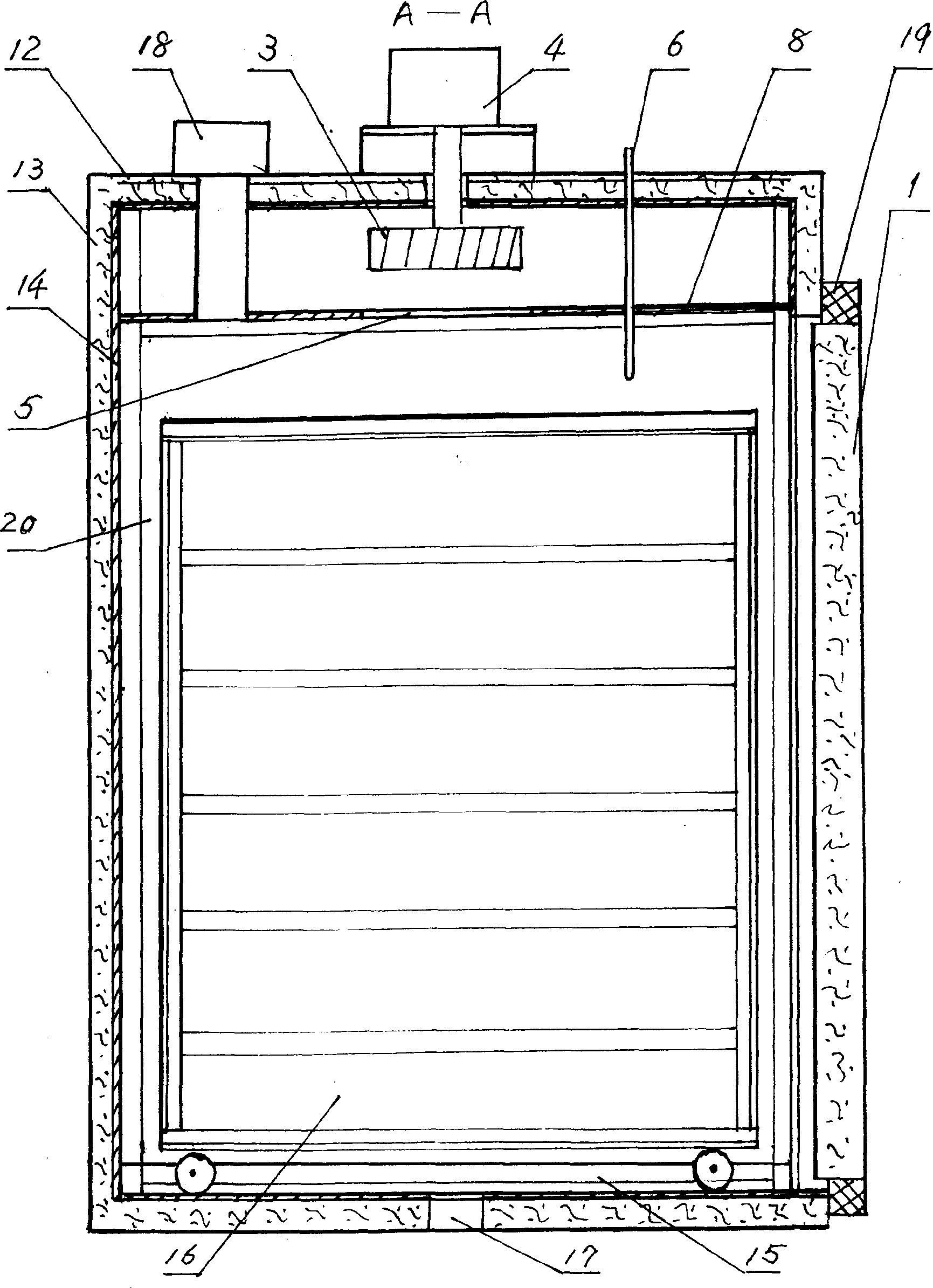

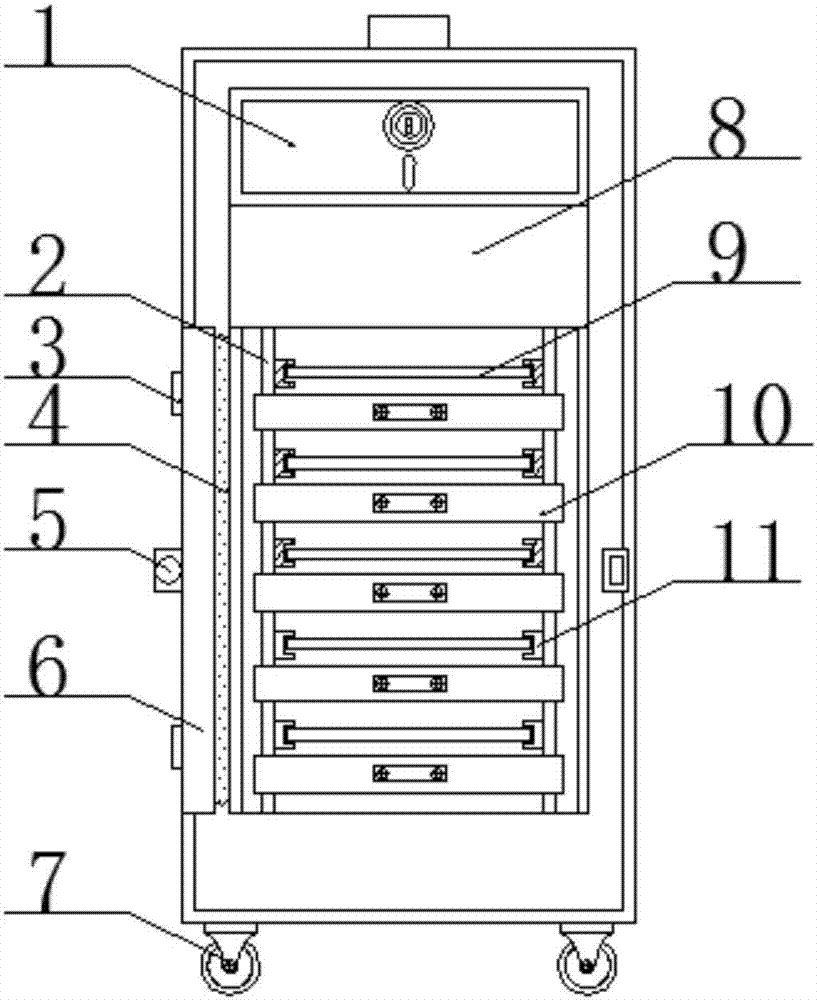

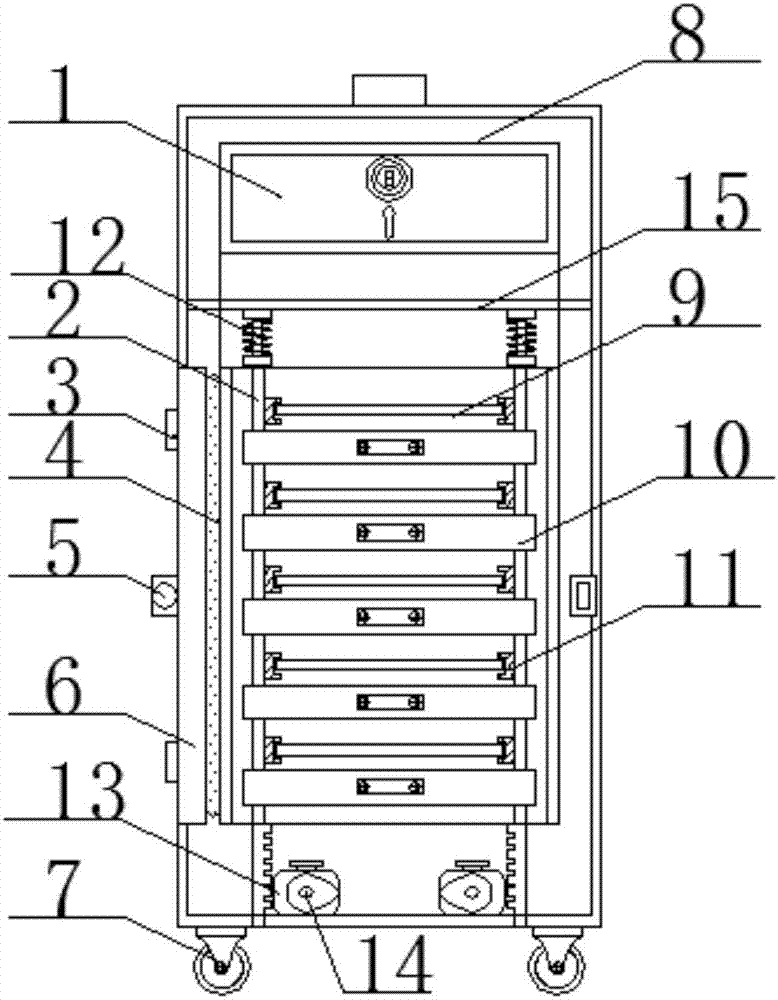

Hot-air circulation type electric oven for shoe-making

InactiveCN1692854AIncrease the effective use of spaceEasy dischargeShoemaking devicesMechanical engineeringEnergy consumption

A hot air circulating electric oven for making shoes is composed of door, case body with left, right and top air channels, temp controller, electrothermal tubes arranged in left and right air channels, the motor and fan arranged in top air channel, a drying chamber, and a feeding carrier in said drying chamber. Its advantages are less energy consumption and high drying quality.

Owner:姚宏达

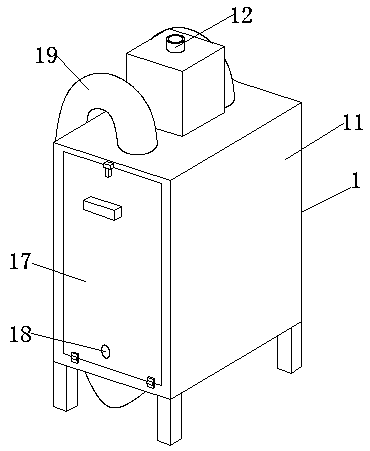

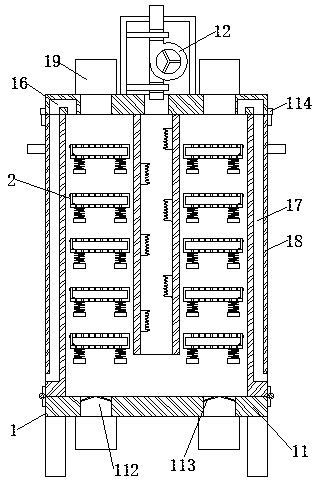

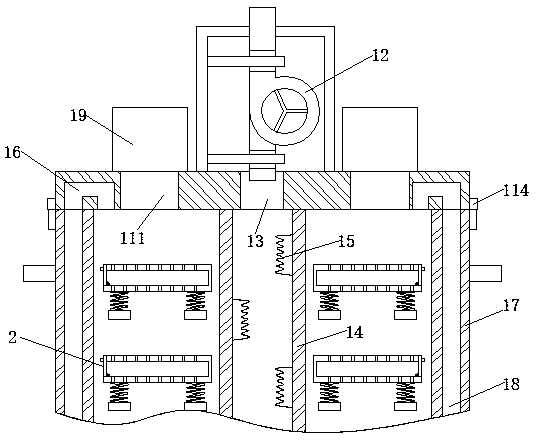

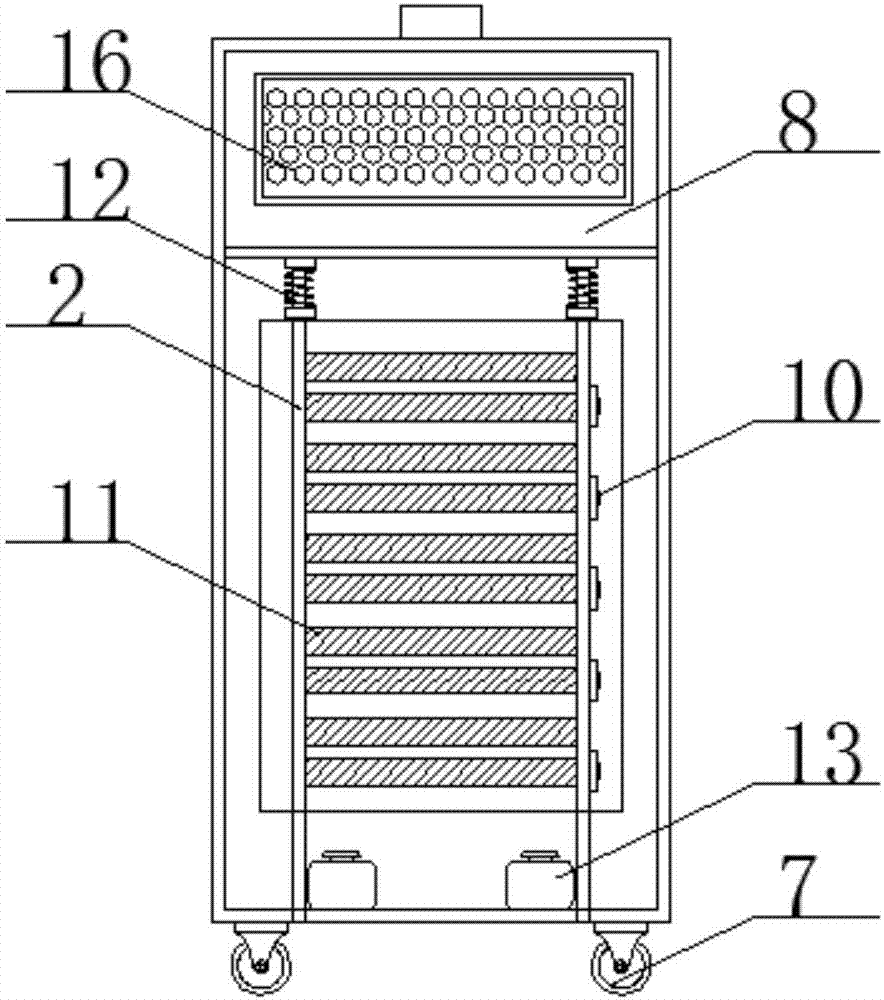

Environment-friendly circulating drying device for edible mushroom processing

PendingCN110887350AImprove drying efficiencyImprove usabilityDrying gas arrangementsDrying chambers/containersProcess engineeringElectric heating

The invention discloses an environment-friendly circulating drying device for edible fungus processing, and relates to the technical field of edible fungus processing equipment. The device comprises acirculating device and a storage device, the storage device is movably arranged in the circulating device, and the circulating device comprises a drying box, an air pump, an air inlet, a sleeve, an electric heating wire, a first exhaust cavity, a box door, a second exhaust cavity and a circulating pipe. A first circulating port, a second circulating port and a box door are arranged, and most airenters the drying box again through the first circulating port, the circulating pipe and the second circulating port to be heated, so the problem that energy is wasted due to the fact that heated airof a conventional drying device is directly exhausted at a time is solved, a small part of air enters the second exhaust cavity through the first exhaust cavity, the box door is continuously heated and then the air is exhausted out of the box door, so the drying efficiency in the drying box is further improved, and the usability of the device is improved.

Owner:株洲市金盟熹农业科技股份有限公司

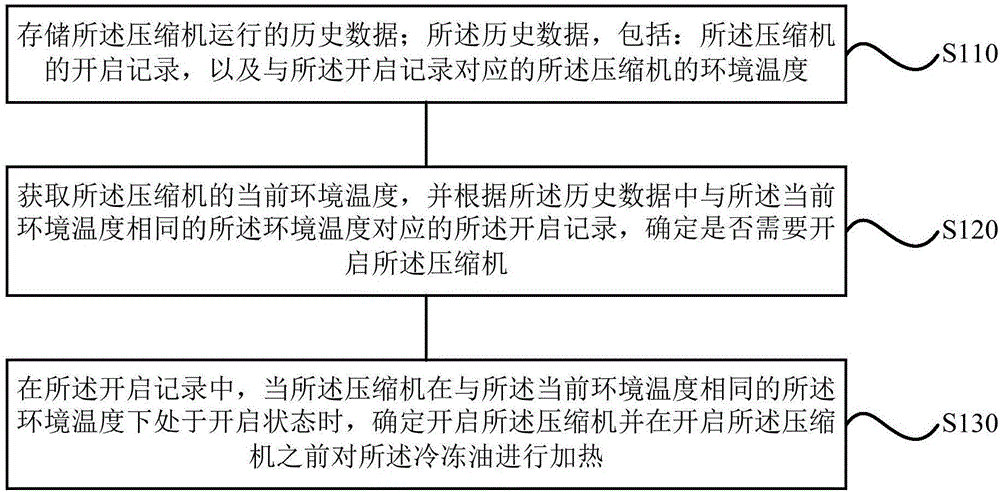

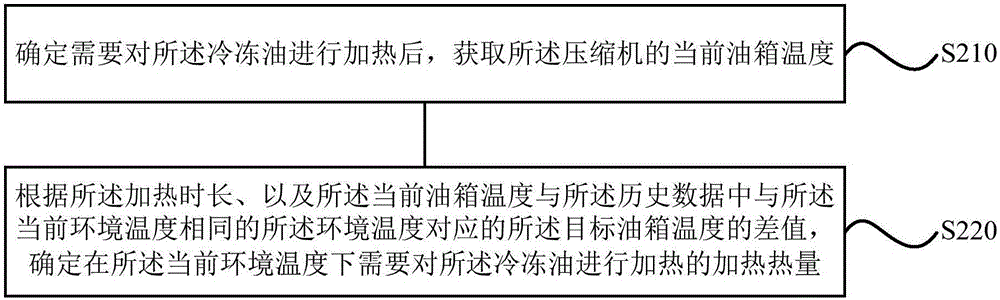

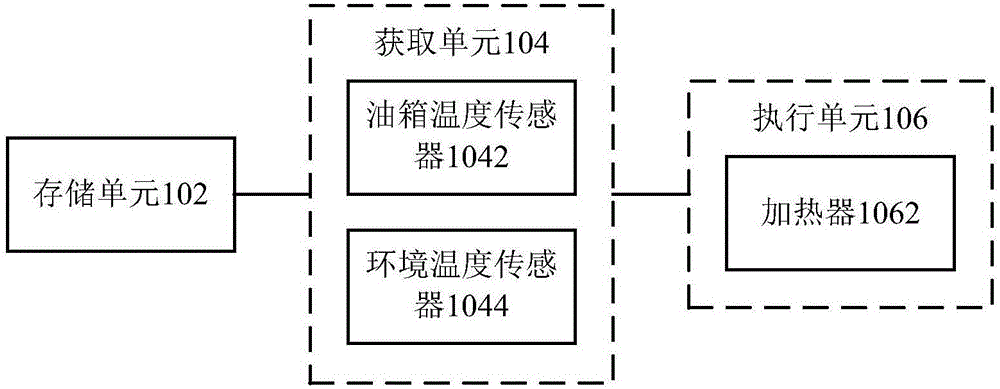

Refrigerant oil heating method and device of compressor and compressor

ActiveCN106247684AAvoid heating timeAvoid wastingCompressorRefrigeration safety arrangementEngineeringConservation energy

The invention discloses a refrigerant oil heating method and device of a compressor and the compressor. The method comprises the steps that historic data for operation of the compressor are stored, specifically, the historic data comprise the start records of the compressor and the environment temperatures, corresponding to the start records, of the compressor; the current environment temperature of the compressor is obtained, and whether to start the compressor or not is determined according to the start record corresponding to the environment temperature, identical with the current environment temperature, in the historic data; and according to the start records, if the compressor is in a starting state at the environment temperature identical with the current environment temperature, it is determined that the compressor is started, and refrigerant oil is heated before the compressor is started. Through the scheme, the defects of long preheating time, low reliability, energy waste and the like in the prior art can be overcome, and the beneficial effects of short preheating time, high reliability and energy conservation are achieved.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Novel spinning drying machine

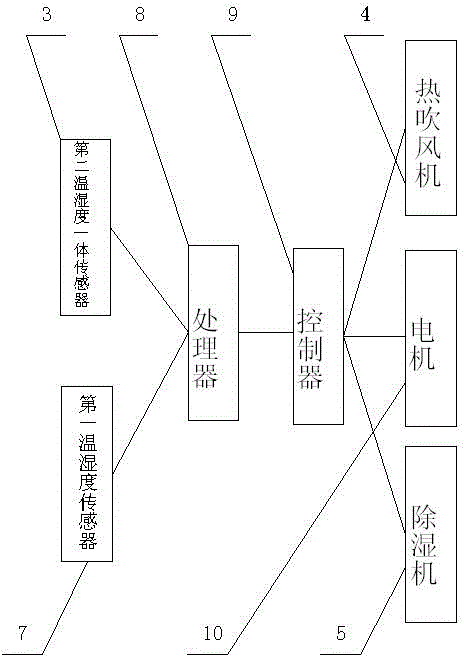

InactiveCN106152749ASolve wasted energySolve the problem of poor drying effectDrying machines with progressive movementsDrying solid materialsPulp and paper industryAir blower

The invention discloses a novel spinning drying machine. The novel spinning drying machine comprises a drying machine body, rollers, a second temperature and humidity integrated sensor, a hot air blower, a dehumidifier, a drying chamber, a first temperature and humidity integrated sensor, a processor, a controller and a motor, wherein the drying chamber is arranged in the drying machine body. Compared with the prior art, the novel spinning drying machine has the beneficial effects that the problem that an existing spinning drying machine causes energy waste and is poor in drying effect is solved; the humidity of cloth is monitored in real time through the second temperature and humidity integrated sensor, and the cloth is delivered after being dried; and by feeding wet cloth to be dried, the effect that the cloth is dried can be ensured, and no extra energy is wasted for the dried cloth, so that energy is saved.

Owner:江苏常朔针纺纱科技有限公司

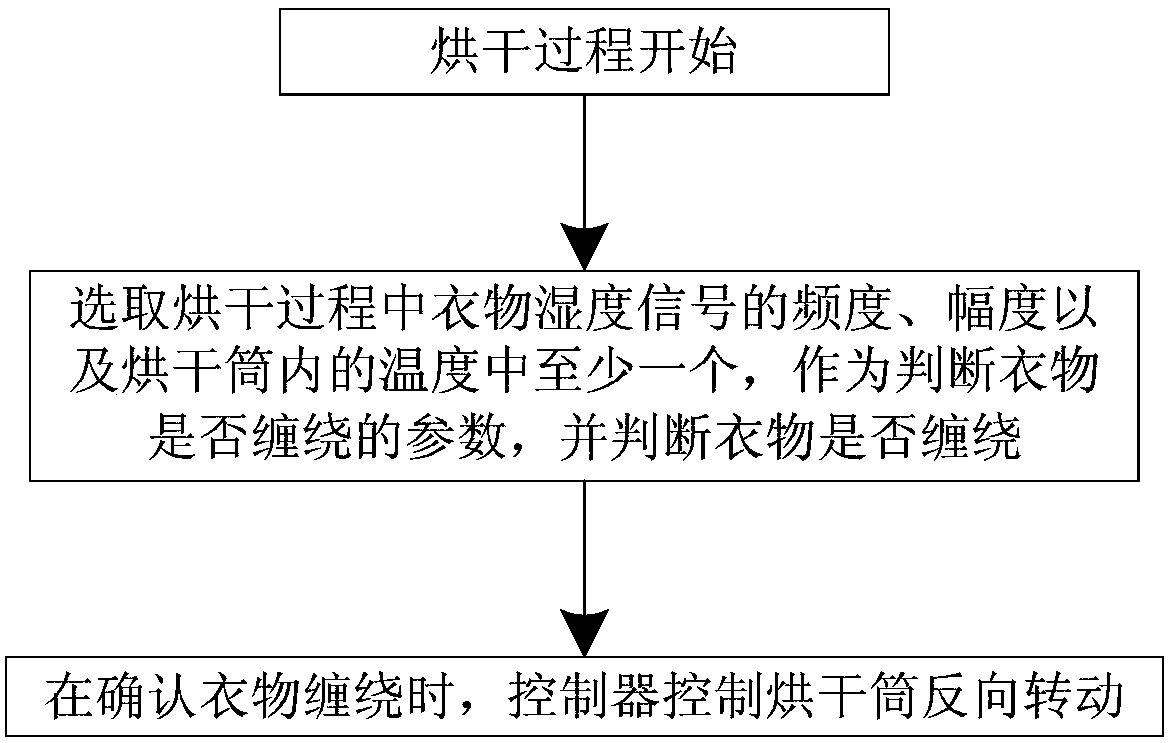

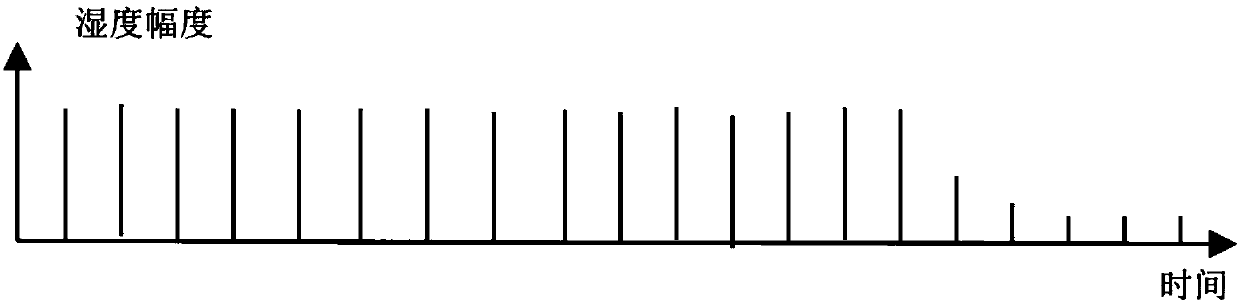

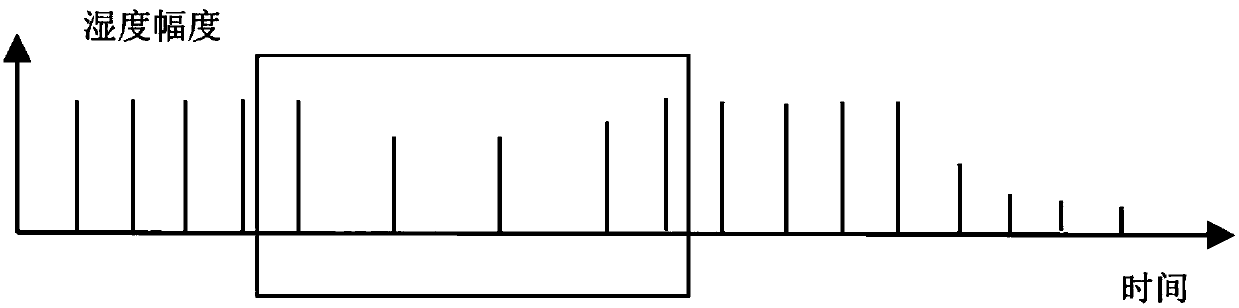

Clothes drying equipment and clothes tangling detection method thereof

ActiveCN110004685ASolve the entanglementSolve wear and tearControl devices for washing apparatusTextiles and paperSwitching frequencyProcess engineering

The invention relates to the field of clothes drying and discloses clothes drying equipment and a clothes tangling detection method thereof. A humidity detection device used for contact detection of clothes humidity and connected to a controller of the clothes drying equipment is arranged in a drying drum of the clothes drying equipment. The method includes steps: in a drying process, selecting atleast one of humidity frequency and humidity amplitude of clothes humidity signals and the internal temperature of the drying drum as parameters for judging whether clothes are tangled or not, and judging whether the clothes are tangled or not; after clothes tangle is confirmed, the controller controls the drying drum to rotate reversely. The clothes tangling detection method of the clothes drying equipment is simple and efficient. When clothes tangle is confirmed, the drying drum rotates reversely to solve the problem of clothes tangle, and the drying drum does not rotate reversely again until next clothes tangle is confirmed, so that switching frequency of forward and reverse rotation of the drying drum is reduced, and problems of abrasion of clothes and the drying equipment and energywastage caused by frequent forward and reverse rotation are solved.

Owner:上海海尔洗涤电器有限公司 +1

Preheating device for fuel oil engine

InactiveCN1667263AAchieve warm-upTroubleshoot startup problemsMachines/enginesEngine startersAutomatic controlMechanical wear

The invention discloses a preheat device before the fuel machine starting that could use extra AC or the electric power the fuel machine carried itself to realize automatic control. It is made up of heating component, earth leakage protection device, switch, power supply and wire. The benefit of the invention is that: realizing fuel machine preheating in a short time, thus, it solving the problem of fuel machine is difficult to start under low temperature condition, abnormal mechanical wear, energy wasting and environment pollution.

Owner:宋志宏

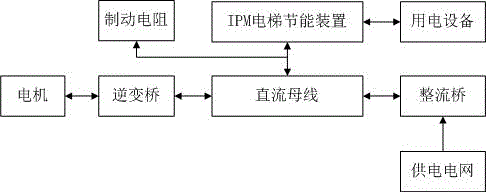

Efficient elevator energy-saving device

InactiveCN106276437ASolve wasted energySolve high temperatureElevatorsHoisting equipmentsAlternating currentResistor

The invention discloses an efficient elevator energy-saving device. The efficient elevator energy-saving device comprises a motor, a power supply network, a brake resistor, an IPM elevator energy-saving device, an inverter bridge, a direct current bus, a rectifier bridge and current-using equipment, wherein the inverter bridge is used for providing direct current for the motor, and transmitting regenerated electricity generated by the motor to the direct current bus; the direct current bus transmits electric energy to the brake resistor; the brake resistor is a carrier of regenerated energy of the motor; the IPM elevator energy-saving device is used for absorbing and storing the regenerated energy received by the brake resistor; and the rectifier bridge is used for converting alternating current provided by the power supply network into direct current and transmitting the direct current to the direct current bus. According to the efficient elevator energy-saving device, the IPM elevator energy-saving device provided by the invention replaces a brake unit of the prior art, energy originally consumed on the brake resistor is quickly fed back to the network to be utilized by devices around a local area network, and the problems of energy waste of the elevator and high temperature are solved.

Owner:成都英格瑞德电气有限公司

Quick timing controller of mechanical electric water heater

InactiveCN105716292ASolve the problem of not being able to timeSolve wasted energyFluid heatersEngineeringAlternating current

The invention relates to a quick timing controller for a mechanical version of an electric water heater, which is characterized in that it includes: a 220V AC power supply, a long-delay charging circuit, a monostable circuit, a mechanical version of an electric water heater control circuit, a working state indicating circuit, and a 12V half-wave rectification filter Stabilized power supply; the model adopted by the time base circuit IC1 in the monostable circuit is NE555. The mechanical version of the quick timing controller for the electric water heater of the present invention only adds a few common components to the delay circuit of the typical time base circuit, which realizes the purpose of the ultra-long delay circuit made with the time base circuit. This not only solves the problem that the mechanical version of the electric water heater cannot be timed, but also solves the problem of wasting energy due to repeated heating after the mechanical version of the electric water heater is powered on. On the basis of not changing the typical delay circuit made by using the time base circuit, it effectively solves the technical problem that has not broken through the ultra-long delay of the time base circuit for a long time.

Owner:吴建堂

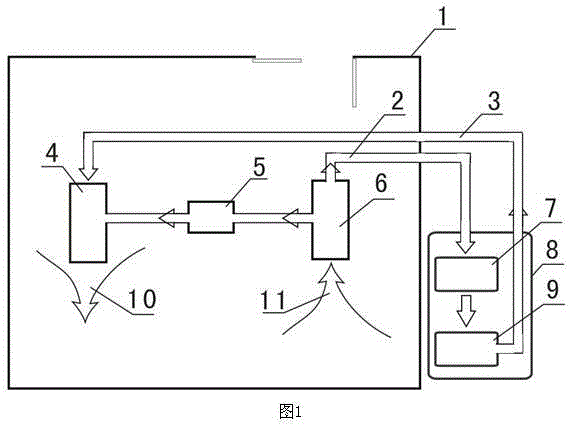

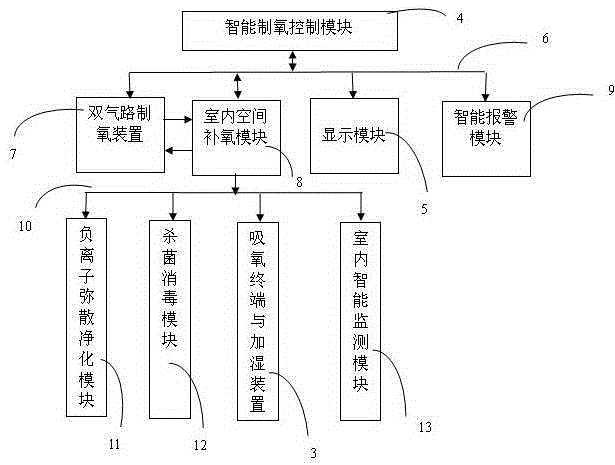

Double-gas-path oxygen-enriched air circulation system

InactiveCN105783171AAvoid quality problemsSolve wasted energySpace heating and ventilation safety systemsLighting and heating apparatusData displayControl system

The invention relates to a double-gas-path oxygen-enriched air circulation system. The double-gas-path oxygen-enriched air circulation system comprises a control system, an oxygen-enrichment fan unit, an air draft opening, an air inlet, an air purification system, an air temperature and humidity adjusting system, and an indoor and outdoor data display system, wherein an oxygen generator and an oxygen-enrichment fan are arranged in the oxygen-enrichment fan unit; the air draft opening communicates with the oxygen-enrichment fan through an air draft pipeline; and the air inlet hermetically communicates with the oxygen generator through an oxygen-enriched air pipe. By adopting the double-gas-path oxygen-enriched air circulation system, the indoor air environment is always kept fresh and clean, and a real oxygen-balanced healthy environment and an oxygen-bar environment can be obtained.

Owner:QINGDAO DAOYIKONGYOU TECH

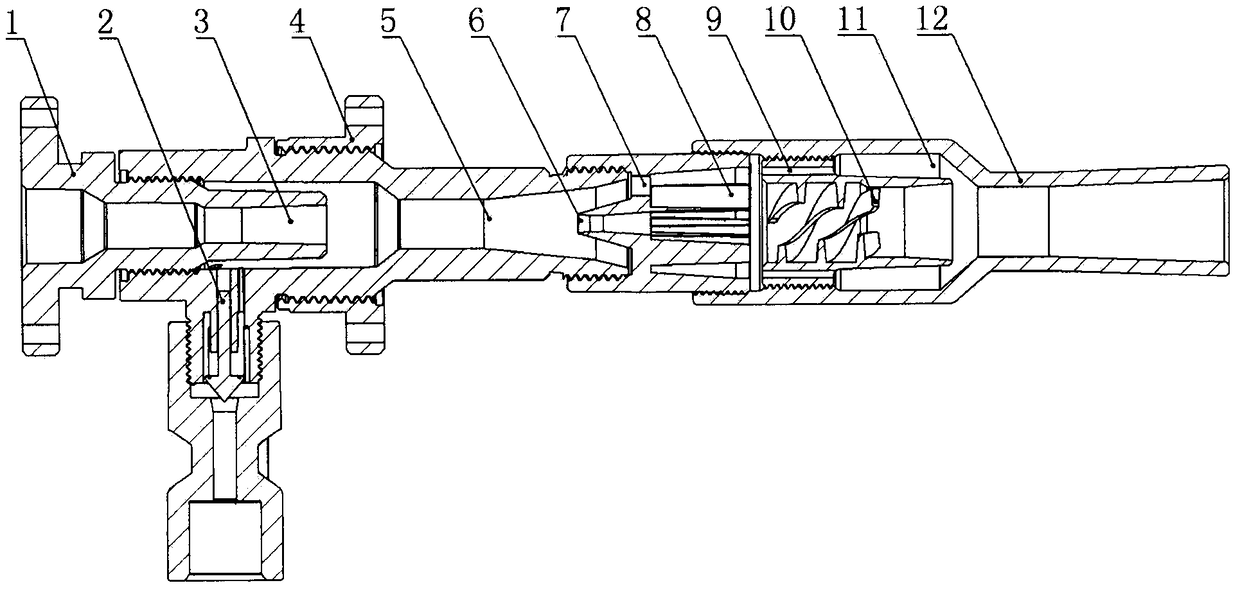

Ozone water continuous film mixing device and method thereof

PendingCN108187517ASolve secondary pollutionSolve wasted energyFlow mixersTransportation and packagingJet flowCavitation

Provided is an ozone water continuous film mixing device and a method thereof. According to the device, a flange sleeves a jet flow gas-water mixer, a pressure water inlet joint is screwed to the front end of the jet flow gas-water mixer, the pressure water inlet joint is provided with a diffusion jet nozzle, the front side face of the jet flow gas-water mixer is connected to an ozone input control valve, the rear end of the jet flow gas-water mixer is connected to a critical cavitation energy diffuser, the inner plane of the critical cavitation energy diffuser is provided with a set of bubblegenerating holes, a rear cavity of the critical cavitation energy diffuser is internally provided with a set of vortex sheets, the rear end of the critical cavitation energy diffuser is connected toan output joint of a diffusion covering film, the front plane in the output joint of the diffusion covering film is provided with a set of covering film holes, the covering film holes are communicatedwith a rotational flow covering film cavity, and a front cavity of the output joint of the diffusion covering film is internally provide with a set of diffusion spinning disks.

Owner:浙江览锐智能科技有限公司

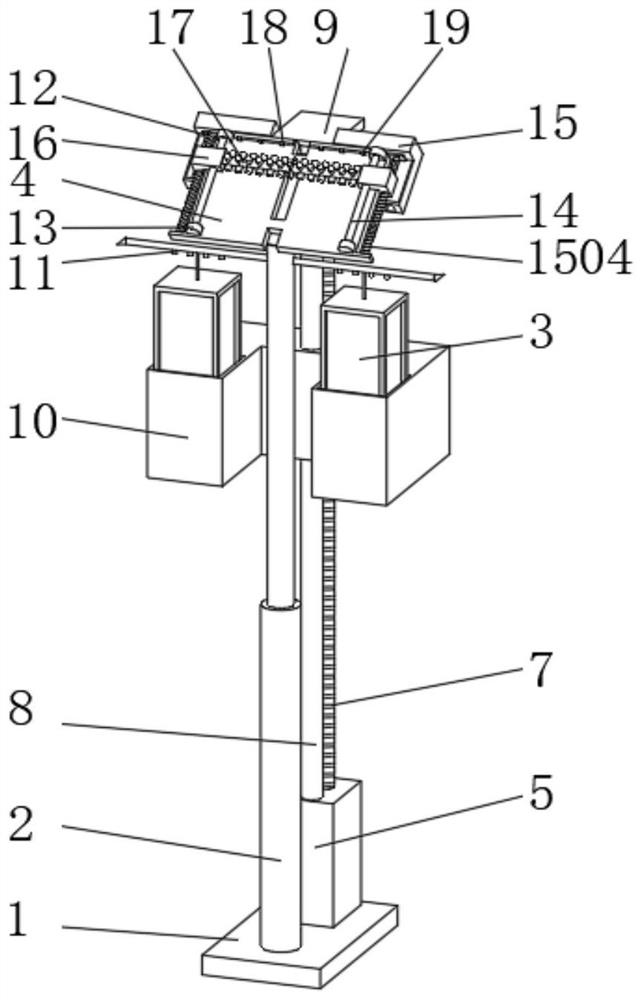

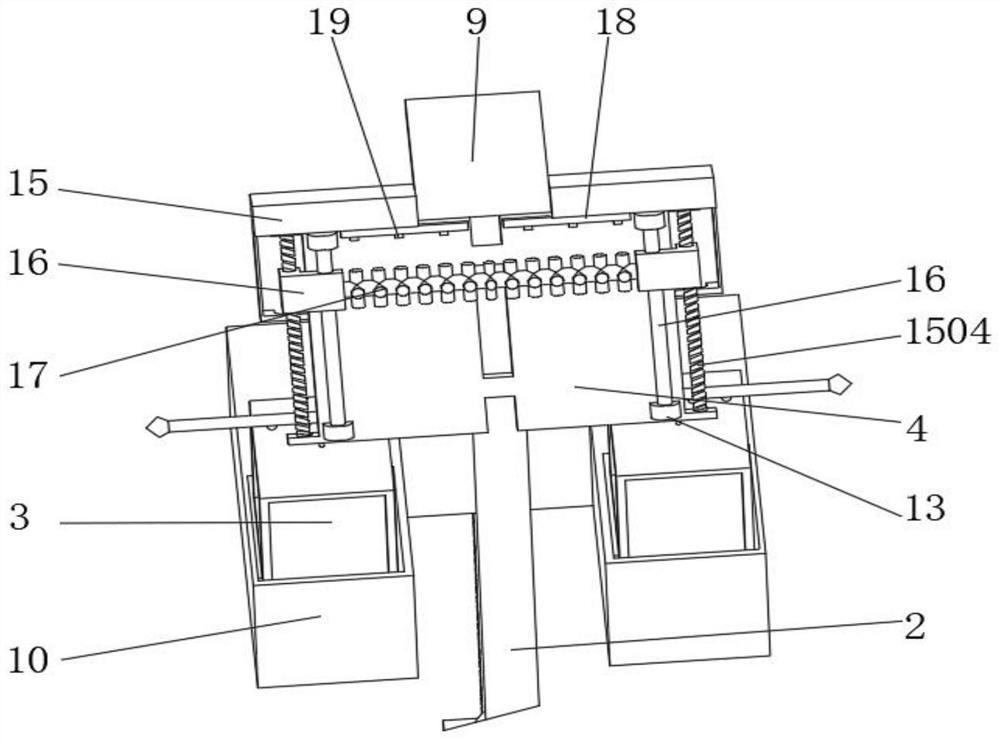

New energy street lamp convenient to clean

InactiveCN111928188AEasy to cleanEasy maintenanceMechanical apparatusLighting support devicesEngineeringStructural engineering

The invention discloses a new energy street lamp convenient to clean. The new energy street lamp comprises a bottom plate, a telescopic rod is fixedly connected to one side of the upper surface of thebottom plate, a connecting rod is fixedly connected to the outer side face of the movable end of the telescopic rod, a street lamp body is fixedly connected to the lower portion of the outer side face of the connecting rod, and a fixing block is fixedly connected to the end face of the movable end of the telescopic rod. By the telescopic rod, the new energy street lamp convenient to clean has theeffect of adjusting the height of the street lamp, therefore, a worker does not need to climb up for maintenance during maintenance, the first threaded rod, the polish rod, the sliding block, the street lamp and the lamp cleaning hole are arranged in a matched mode, in the street lamp cleaning process, only the lamp cleaning hole needs to be cleaned up and down on the outer surface of the streetlamp through the first motor, then the effect of facilitating cleaning is achieved, and the purpose of improving the cleaning efficiency is achieved.

Owner:郑州三骏能源科技有限公司

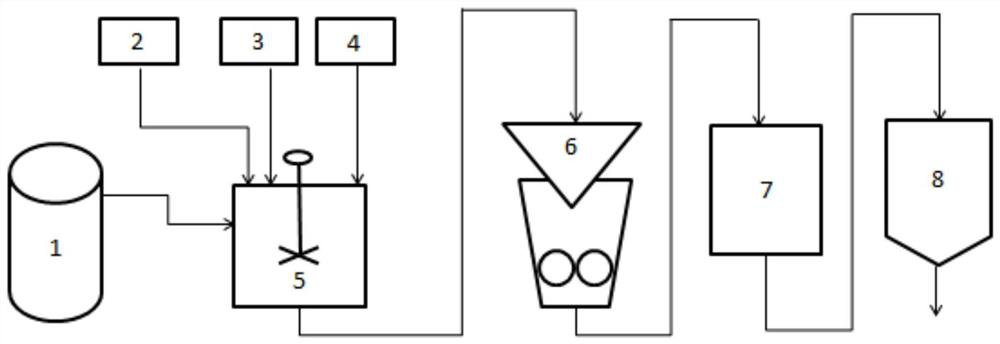

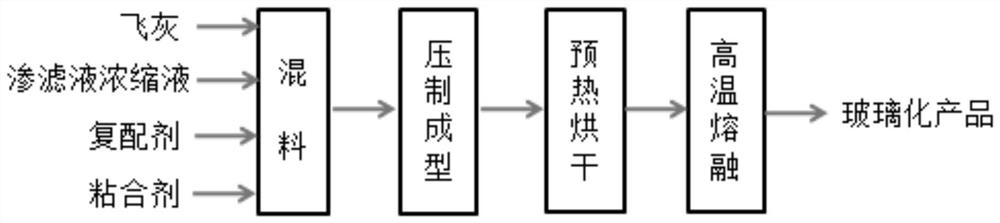

Fly ash melting vitrification pretreatment system and method

PendingCN114538768ASolve wasted energyAddressing requirements for molten vitrificationSolid waste managementMixed materialsWaste management

The invention discloses a fly ash melting vitrification pretreatment system and method, and the system is characterized in that a material mixing unit is provided with a fly ash inlet, a leachate concentrated solution inlet, a binder inlet, a compounding agent inlet and a mixed material outlet, and the material mixing unit is internally provided with a stirrer; the leachate concentrated solution storage unit is provided with a leachate concentrated solution outlet which is connected with the leachate concentrated solution inlet of the material mixing unit; a fly ash outlet of the fly ash storage unit is connected with a fly ash inlet of the mixing unit; a compound agent outlet of the compound agent storage unit is connected with a compound agent inlet of the mixing unit; a binder outlet of the binder storage unit is connected with a binder inlet of the mixing unit; the forming unit is provided with a mixed material inlet and a formed material outlet, and the mixed material inlet is connected with the mixed material outlet of the mixing unit; the drying unit is provided with a formed material inlet and a dried formed material outlet, and the formed material inlet is connected with the formed material outlet of the forming unit. According to the system and the method, fly ash molded products meeting requirements can be prepared.

Owner:SOUND ENVIRONMENTAL RESOURCES

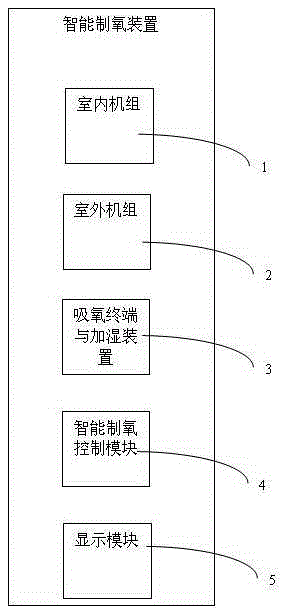

Automatic oxygen generation equipment

InactiveCN106642307AThe air environment is always cleanSolve wasted energyMechanical apparatusSpace heating and ventilation safety systemsFresh airSignal lines

The invention relates to automatic oxygen generation equipment which comprises an indoor unit, an outdoor unit and an intelligent oxygen generation control module. The indoor unit is connected with an oxygen inhalation terminal and a humidification device. The intelligent oxygen generation control module is connected with a dual-gas-path oxygen generation control device through a set of module signal lines. The dual-gas-path oxygen generation control device is installed in the indoor unit. An indoor space oxygen supplementation module is installed in the dual-gas-path oxygen generation control device. By the adoption of a dual-gas-path circulating system, no matter what the indoor temperature is, the machine reduced temperature is almost equal to indoor temperature, and the problem that energy is wasted during fresh air exchange is solved.

Owner:王欣欣

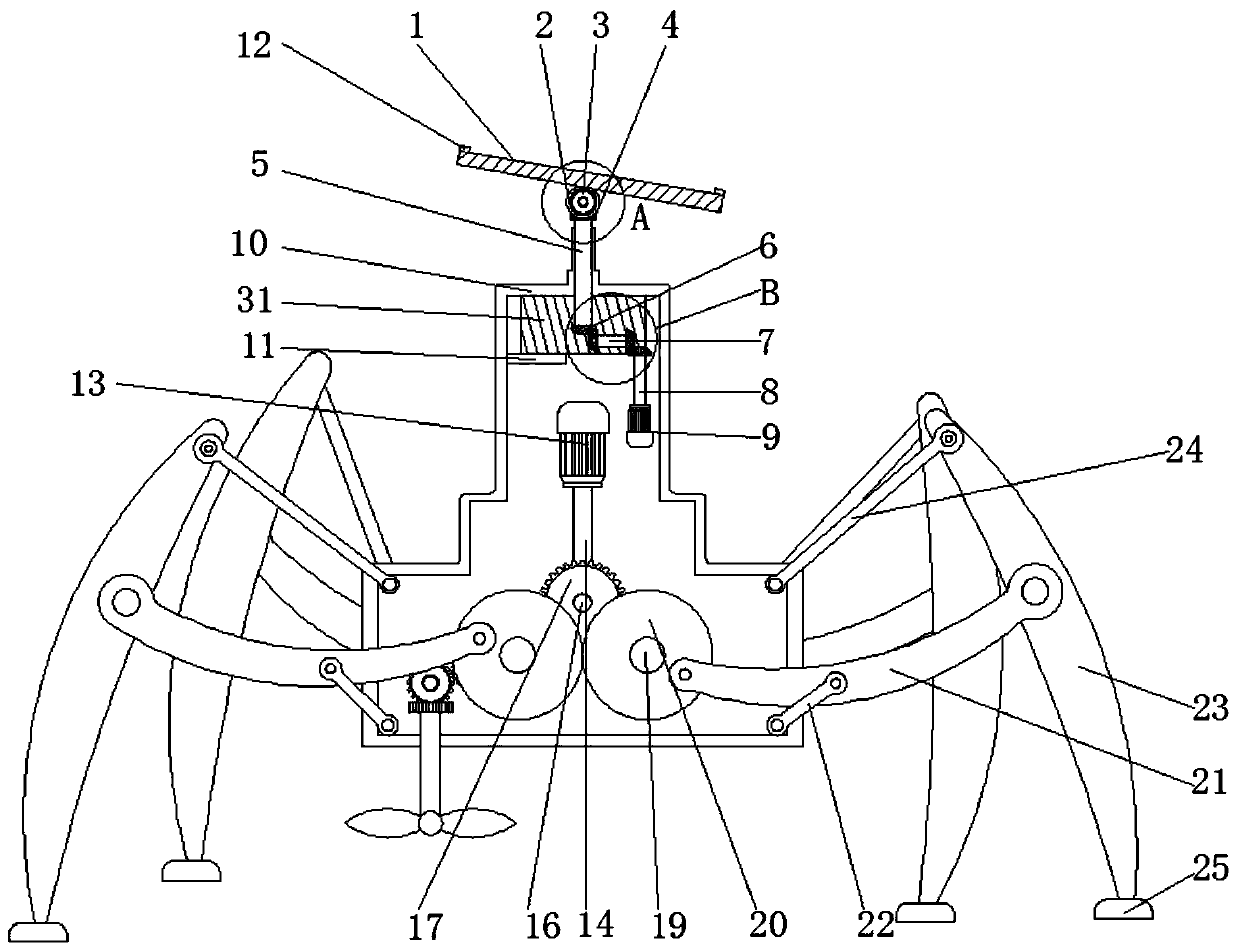

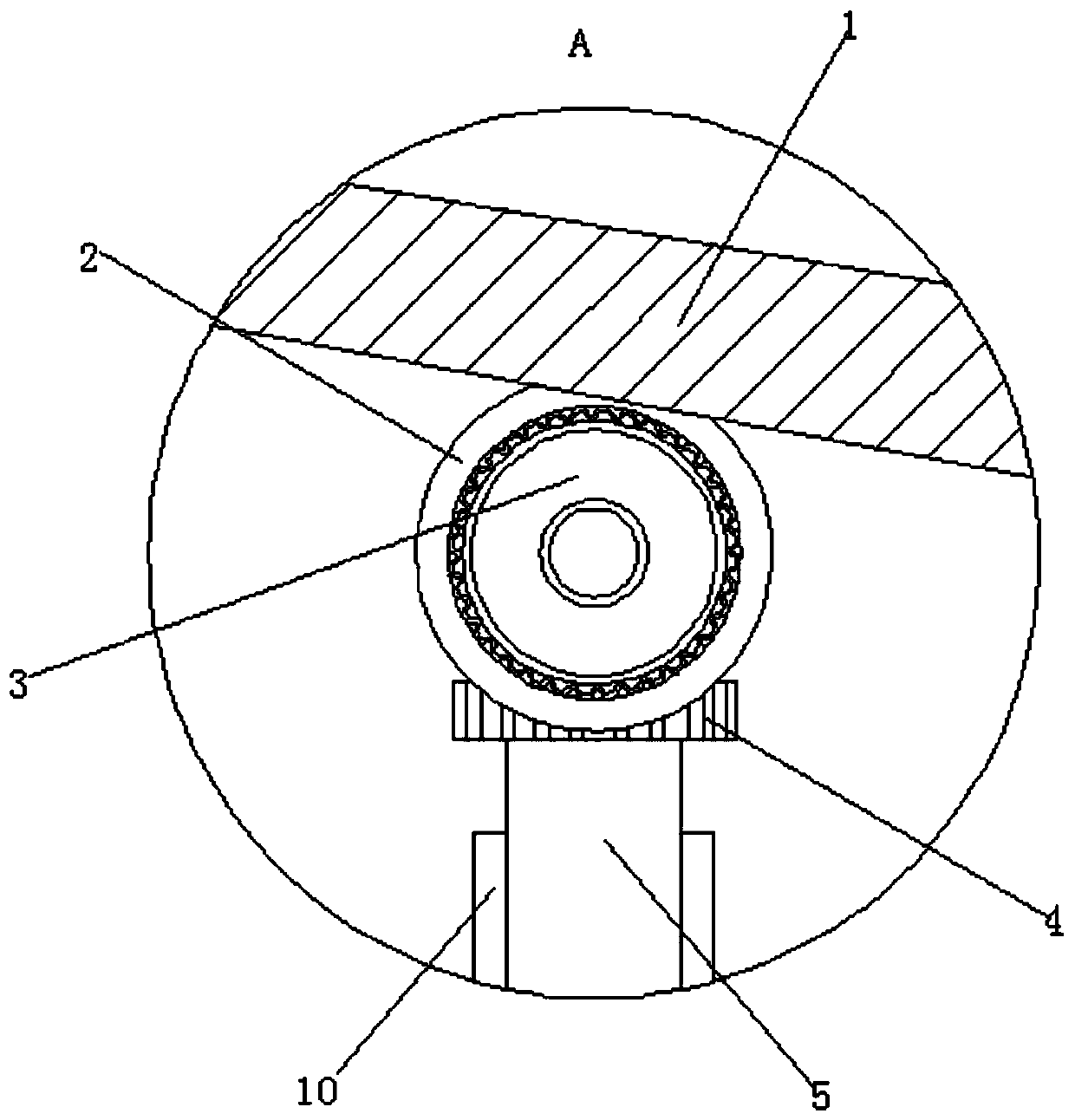

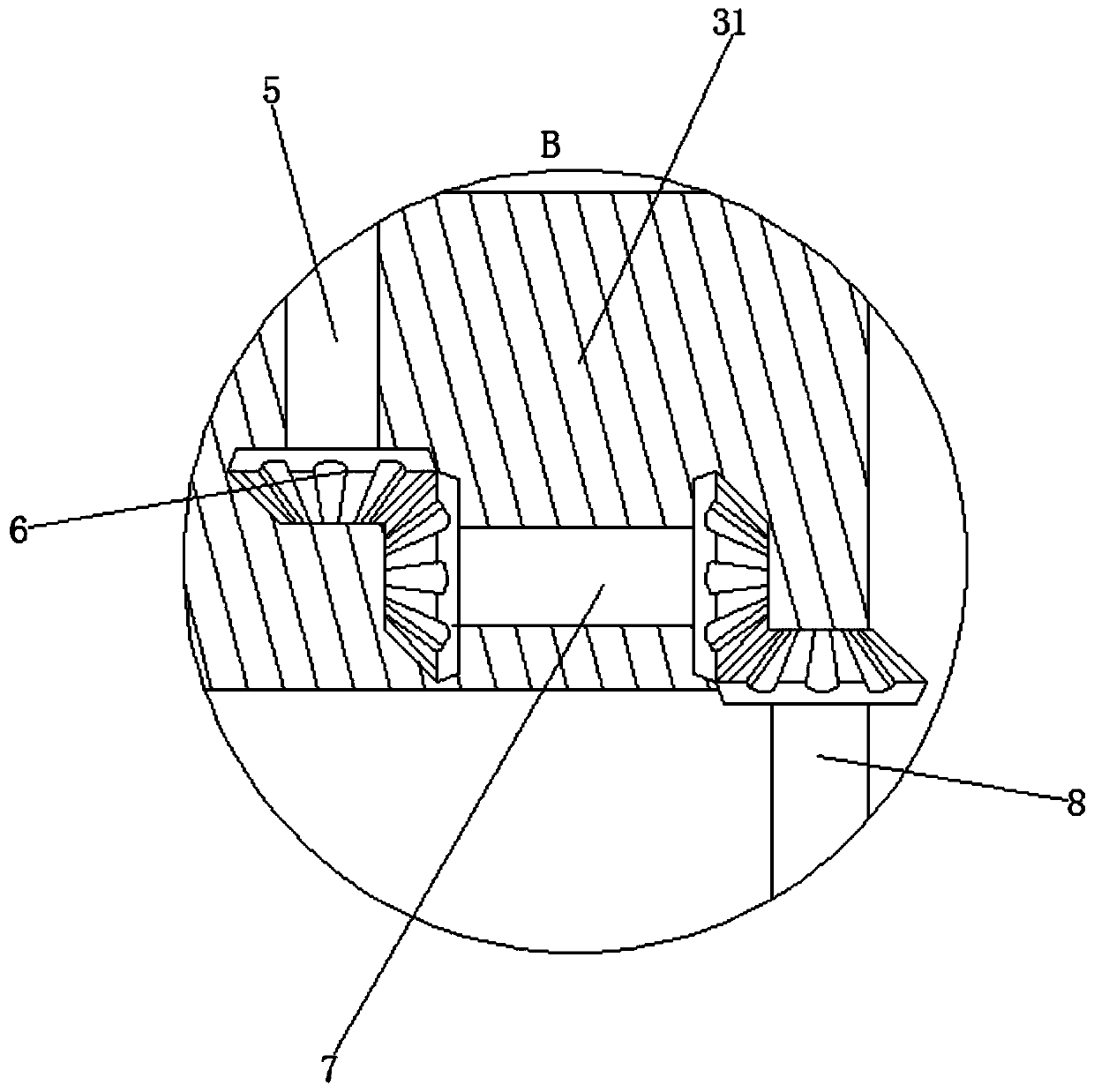

Bionic-based walkable automatic solar micro weeding device

InactiveCN111357469ASolve wasteSolve wasted energyPhotovoltaic supportsMowersElectric machineryElectricity system

The invention relates to the technical field of new energy equipment and discloses a bionic-based walkable automatic solar micro weeding device which comprises a solar panel, wherein a mounting ring is moveably connected with the bottom of the solar panel; a first rotating gear is moveably connected inside the mounting ring; a cutting device is moveably connected with the bottom end of a third transmission shaft; and a storage battery is moveably connected on a holding platform. According to the bionic-based walkable automatic solar micro weeding device, the solar panel is connected with the mounting ring, and the clean energy, namely solar energy, is used, so that the problem that energy is wasted when weeding machinery is recharged with power can be solved to a large extent; an input shaft is connected with a second motor, so that weeds can be effectively removed; a second transmission shaft is connected with a second transmission gear, eccentric gears are connected with the second transmission shaft, and the eccentric gears are connected with bent levers, so that the problems that a power system used by mechanical equipment self is large in weight, large in size and hard to operate can be greatly solved.

Owner:青祥云

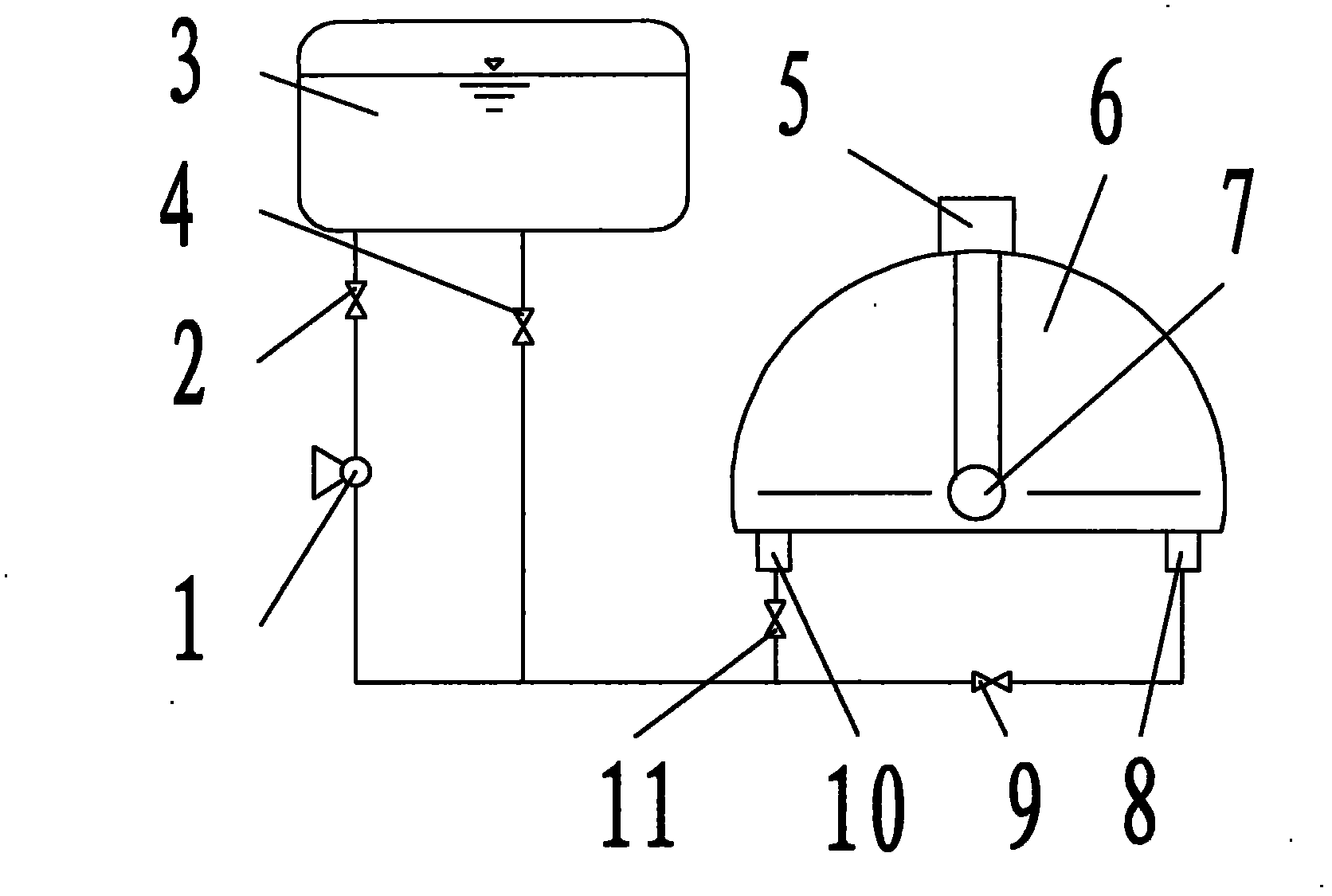

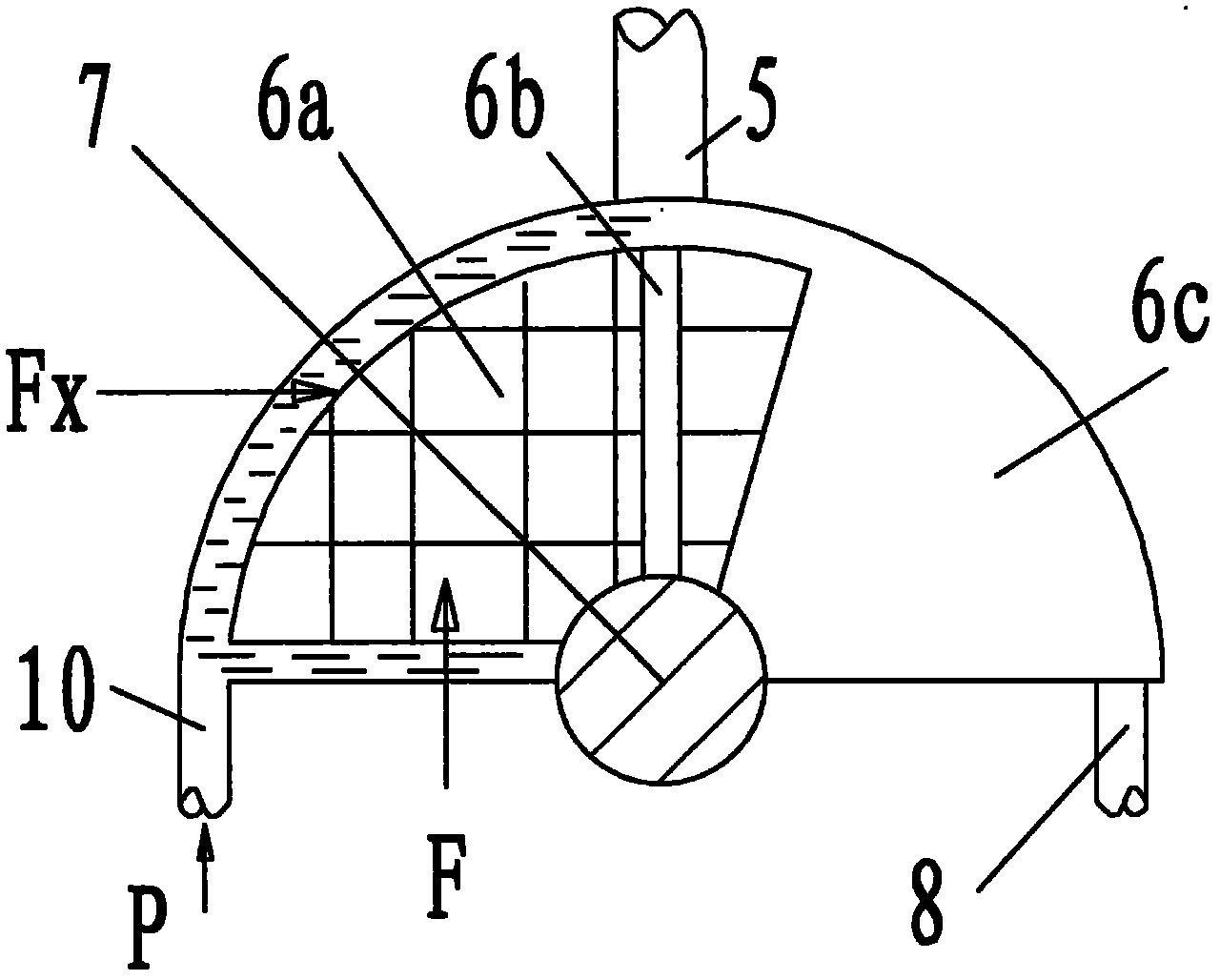

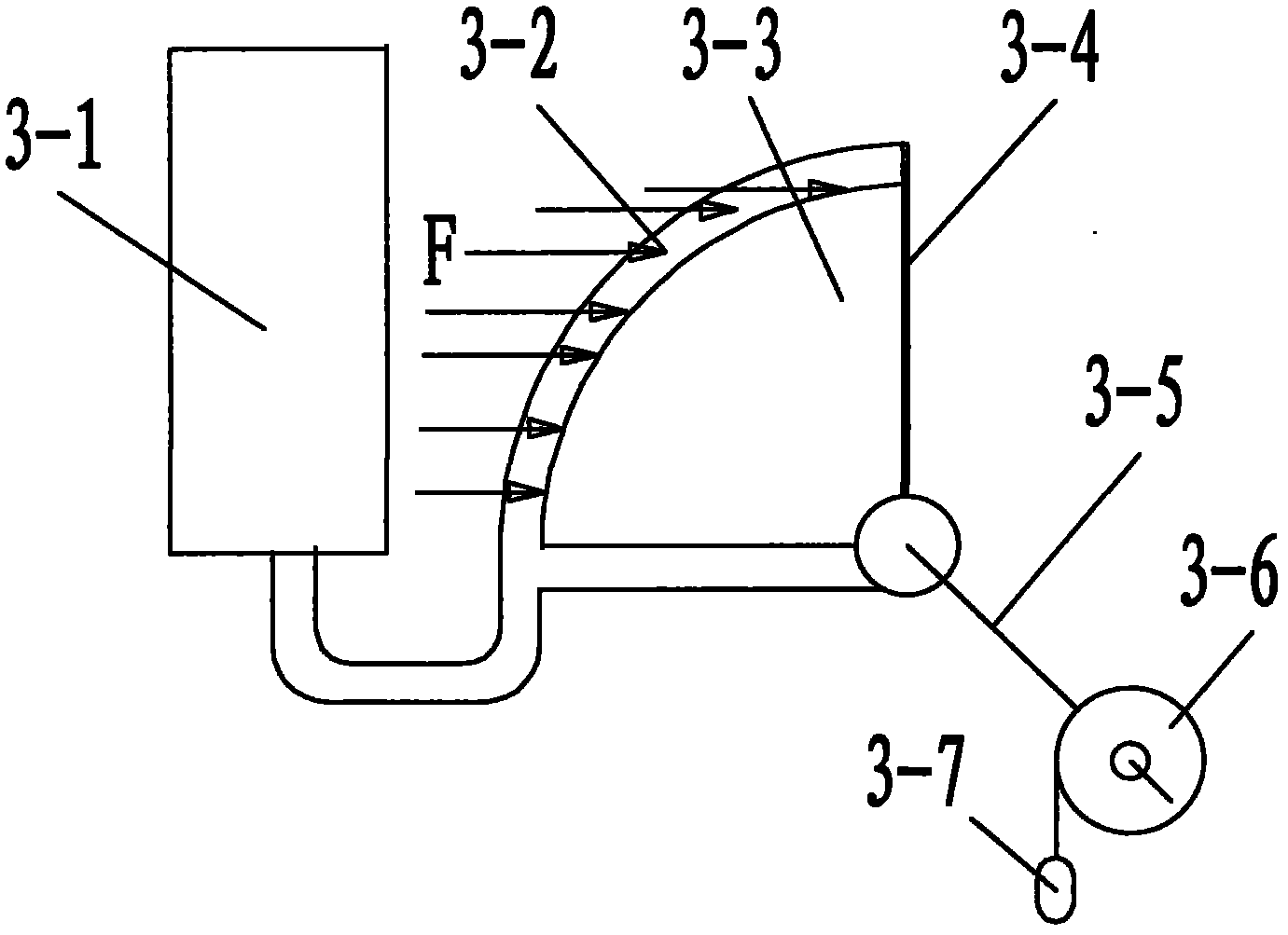

Rotating plunger field energy converter

InactiveCN102182727ASimple structureSolve wasted energyFluid-pressure actuator componentsInternal energyField energy

The invention relates to a rotating plunger field energy converter, which belongs to an energy converter and is characterized in that an outlet of a lift pump is communicated with a liquid storage tank through a valve; an inlet of the lift pump is connected with a liquid outlet of the liquid storage tank and a first liquid inlet / outlet and a second liquid inlet / outlet of an internal energy generator through a pipe control valve and a pipeline control valve; the top part of the internal energy generator is provided with an exhaust port; a floating body of the internal energy generator is connected with an output shaft; and the output shaft outputs a torque to drive mechanical equipment. The invention has the advantages that: the rotating plunger field energy converter has a simple structure, the energy is generated by a carrier under the action of gravity field almost like the fall of an apple, the different point is the potential energy of the floating body which is the unique energy carrier of the rotating plunger field energy converter does not change, the energy return stroke is omitted by utilizing the characteristics of the gravity field, and the practical requirement of continuously-acquired internal energy of liquid is met in an earth gravity system.

Owner:孙荣军

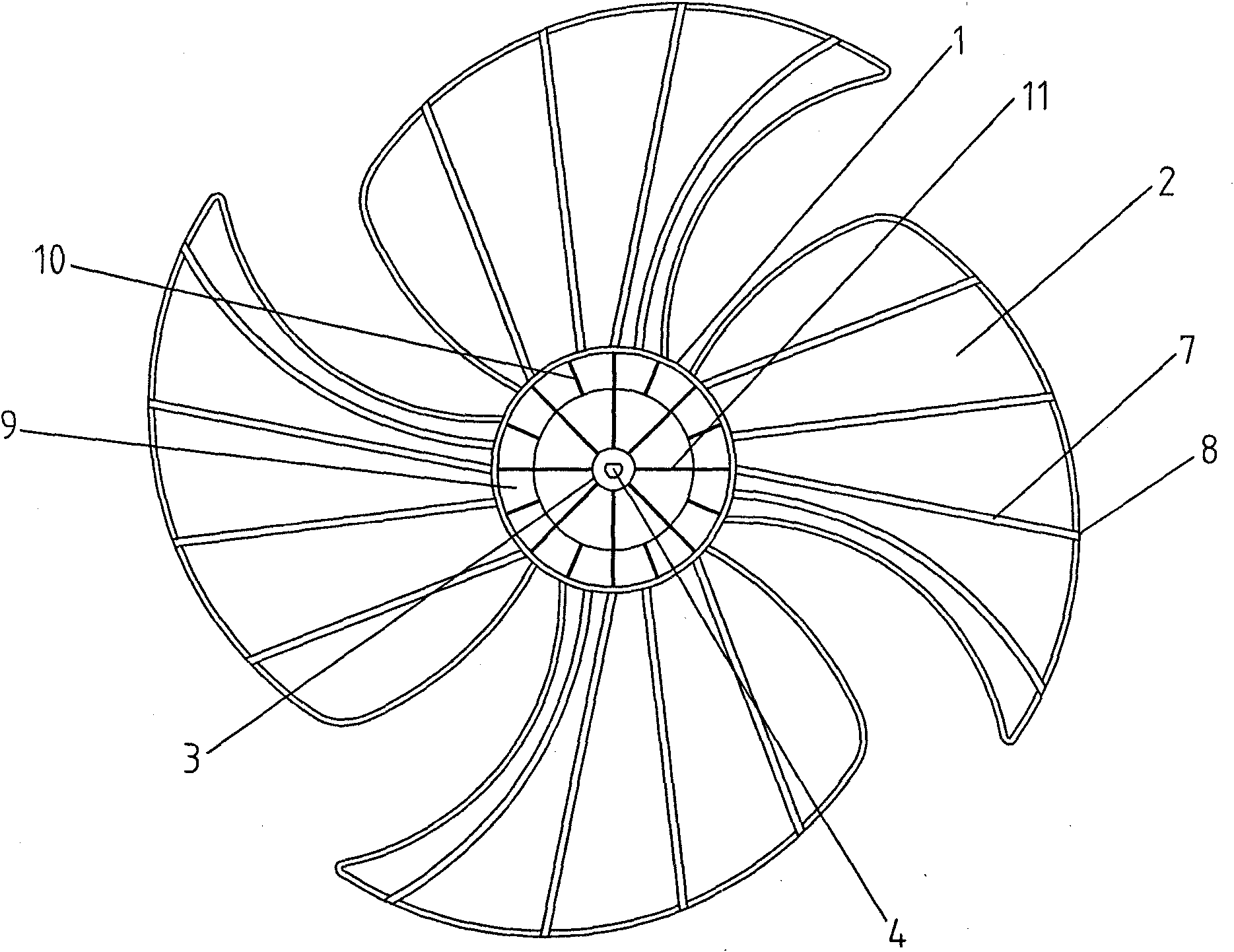

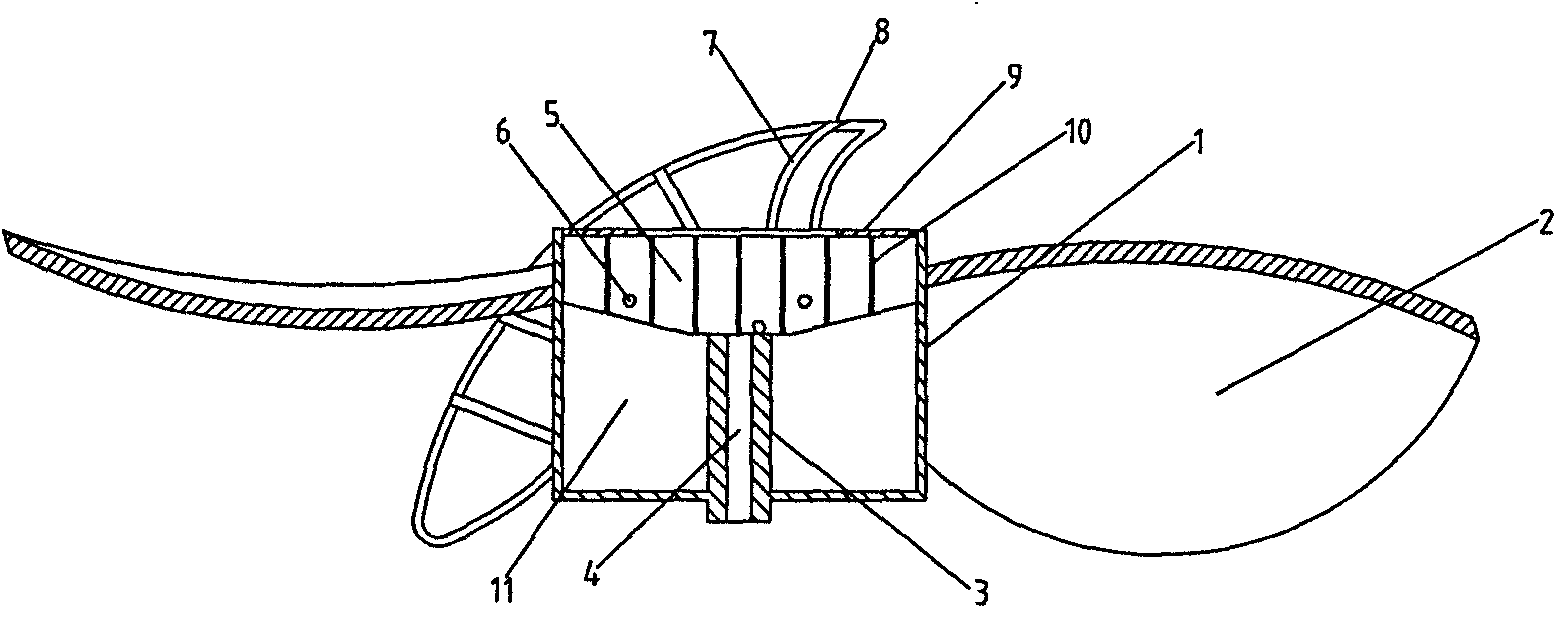

Air-conditioning condensed water atomizer

The invention relates to an air-conditioning condensed water atomizer, which can effectively solve the problems of environment pollution and energy waste caused by improper treatment and halfway evaporation of the current condensed water. The air-conditioning condensed water atomizer is characterized by comprising a blade cylinder and blades, wherein the blades are uniformly distributed on the outer peripheral surface of the blade cylinder; a fixed seat is arranged at the inner center of the blade cylinder; a motor shaft hole is formed on the fixed seat; a plurality of flow equalization grooves are arranged on the inner peripheral surface of the blade cylinder; at least one water outlet hole is formed on the bottom surface of each flow equalization groove; a plurality of water outlet channels which radially extend outwards from the blade cylinder are arranged on the outer peripheral surface of the blade cylinder; the inner end of each water outlet channel is communicated with the water outlet hole on the bottom surface of each flow equalization groove; and a water outlet is arranged at the outer end of each water outlet channel. The air-conditioning condensed water atomizer of the invention has the advantages of novel and unique structure, convenient use and good atomizing effect and is innovation of air-conditioning condensed water atomizing equipment.

Owner:李凯峰

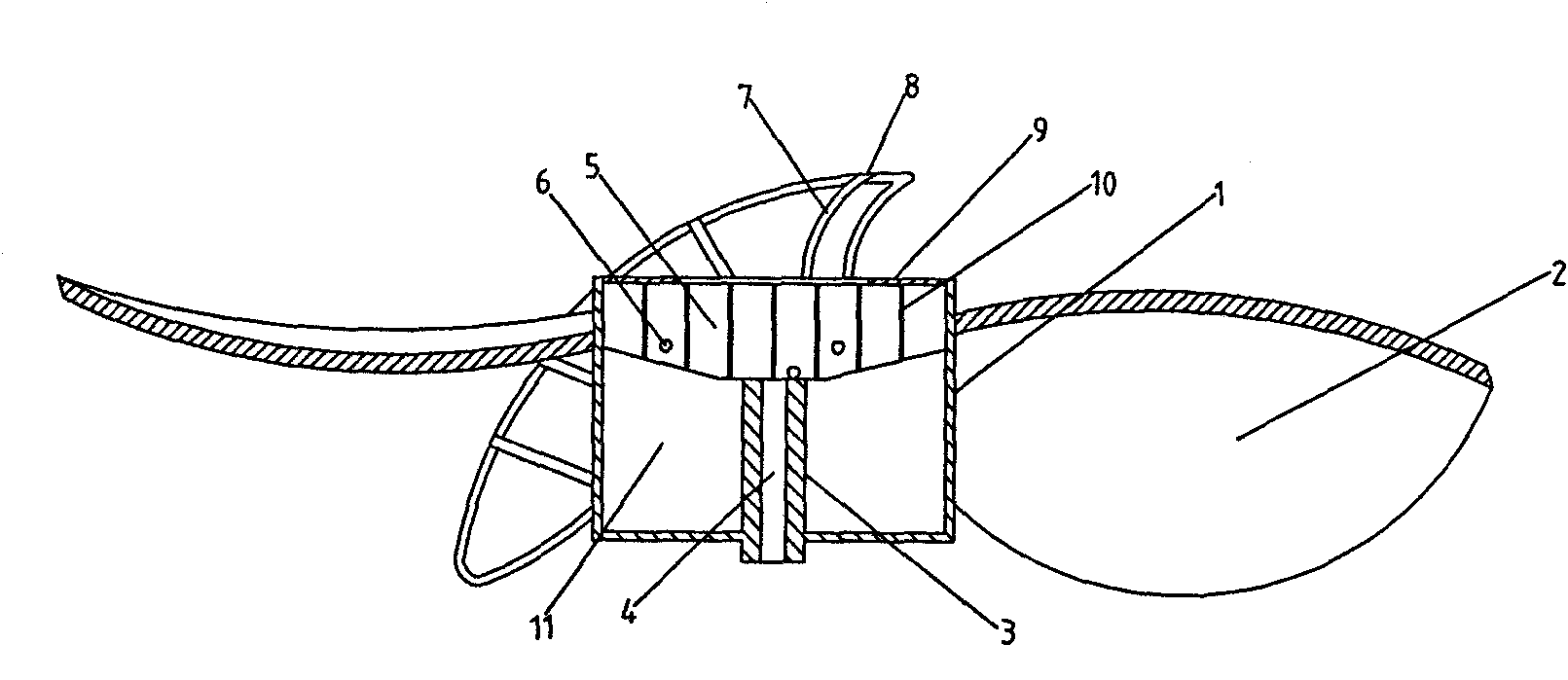

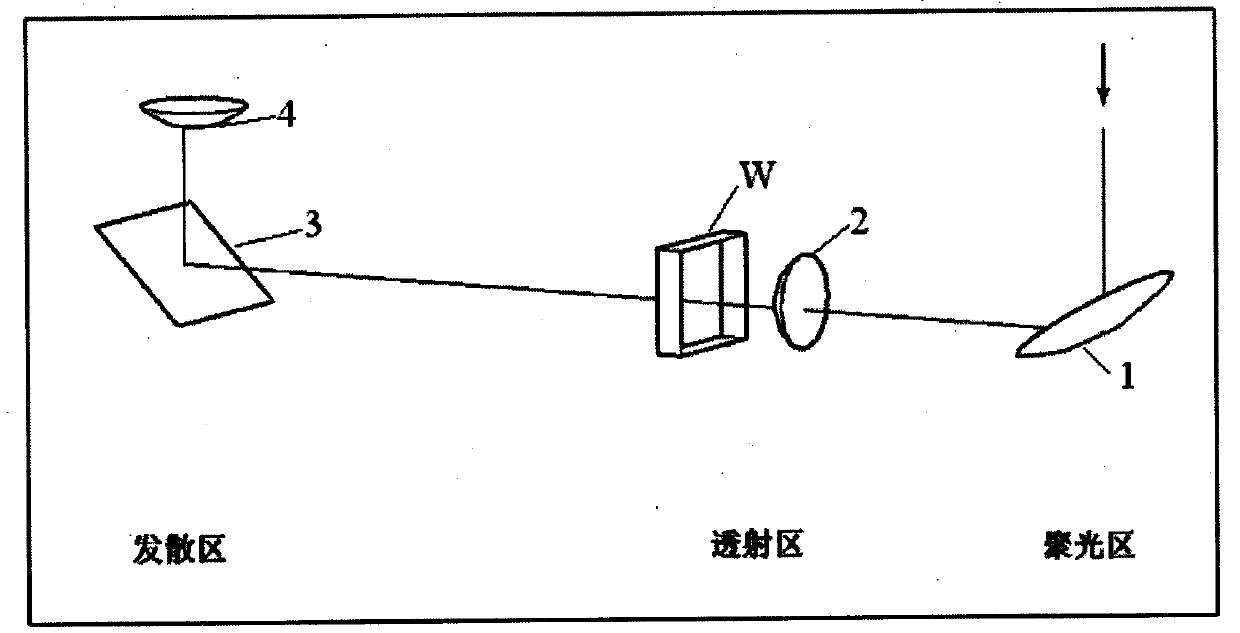

An Automatic Condenser and Scatterer

ActiveCN107388188BIncrease brightnessSolve wasted energyElectric circuit arrangementsUsing daylightBasementScatterometer

The invention provides an automatic light gathering scatterometer. The automatic light gathering scatterometer comprises a light gathering zone, a transmission zone and a divergence zone, wherein the light gathering zone is provided with a concave reflecting mirror which reflects sunlight which perpendicularly irradiates from the above to the ground into unparallel light rays and gathers the light rays to the transmission zone; the transmission zone is provided with a convex transmitting mirror; the light rays gathered at the light gathering zone are allowed to pass through the convex transmitting mirror, parallel light sources are formed, the light sources irradiate a semi-underground garage / semi-basement after passing through a window of the semi-underground garage / semi-basement, and the light sources are reflected to the divergence zone; and the divergence zone is provided with a reflecting mirror surface used for reflecting the light rays reflected from the convex transmitting mirror, and a convex reflecting mirror used for reflecting the light rays reflected by the reflecting mirror surface to the ground in all directions. According to the automatic light gathering scatterometer, sunlight is gathered and then transferred into the semi-underground garage / semi-basement through mirror devices based on the principles that the light rays can be gathered through the concave reflecting mirror and a convex lens and the light sources can be diverged through the convex reflecting mirror, and the effects of transferring the light rays, strengthening brightness and saving energy are achieved.

Owner:SHANGHAI DIANJI UNIV

A blower frequency conversion control device and control method based on power frequency motor

ActiveCN105465029BAvoid surge phenomenonSimple structurePump controlNon-positive displacement fluid enginesFrequency changerControl cell

Owner:XIAOHONGMEN SEWAGE TREATMENT PLANT BEIJING DRAINAGE GRP

Dendrobium drying device

InactiveCN107883680AImprove drying efficiencySolve wasted energyDrying chambers/containersDrying solid materialsWater vaporEngineering

The invention discloses a dendrobium drying device. The dendrobium drying device comprises a dryer body shell, a control cabinet shell is arranged at the upper end of the front surface of the dryer body shell, a dryer door is arranged on one side of the front surface of the dryer body shell, a sealing strip is arranged on one side of the dryer door, and a dryer lock knob is arranged on the other side of the dyer door. A hinge is arranged at the joint position of the dryer door and the dryer body shell, a main supporting shaft is arranged in the dryer body shell, a slide shaft is arranged on one side of the main supporting shaft, a water vapor stopping plate is arranged on one side of the slide shaft, and a dryer drawer is arranged below the water vapor stopping plate. By designing the mainsupporting shaft, an engine and a cam mounted in the dryer body shell, dendrobium in the dryer drawer can be conveniently vibrated, and thus the problem that the drying efficiency is low due to the fact that existing dendrobium is accumulated on the dryer drawer is solved.

Owner:HUOSHAN BAOXINYUAN DENDROBIUM DEV

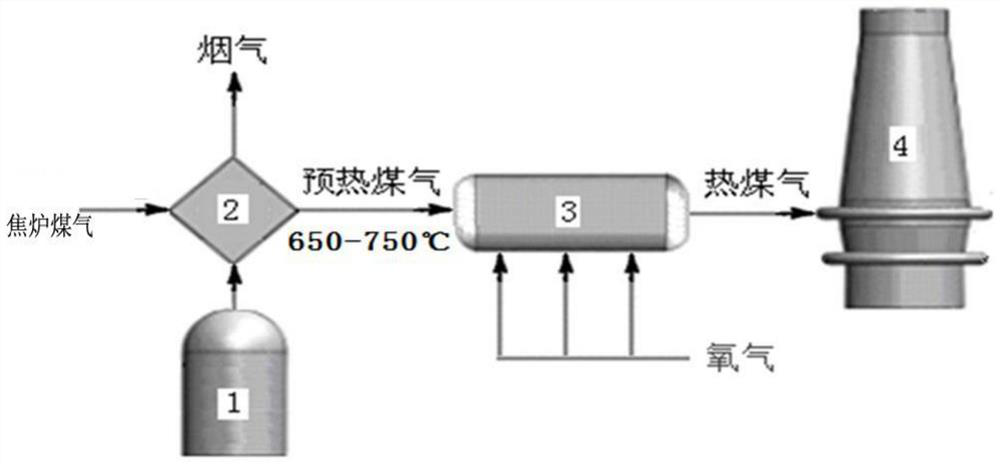

Self-reforming system and method of coke oven gas for blast furnace ironmaking

PendingCN113501494AReduce consumptionQuick restoreHydrogenBlast furnace detailsWater vaporHeat exchanger

The invention belongs to the technical field of coal chemical industry, and discloses a self-reforming system and method of coke oven gas for blast furnace ironmaking. The system comprises a flue gas generator, a heat exchanger, a coke oven gas self-reforming furnace and a blast furnace. The method comprises the steps of feeding coke oven gas into the heat exchanger for preheating through a gas conveying pipeline, feeding the preheated coke oven gas into the coke oven gas self-reforming furnace through the gas conveying pipeline, introducing oxygen into the coke oven gas self-reforming furnace to combust and reform CH4, CO2 and water vapor in the coke oven gas into reducing gases CO and H2, and spraying the reducing gases into a blast furnace for ironmaking. According to the invention, rapid reduction can be realized, blast furnace coke consumption can be reduced, a coking process and steel generation are organically combined, the problems of energy waste and environmental pollution caused by emptying and burning of residual coke oven gas during tempering co-production ethylene glycol maintenance are solved, relatively great economic benefits can be obtained, relatively great social and environmental benefits can also be obtained at the same time, and a demonstration effect is also achieved for efficient utilization of coke oven gas of steel enterprises in China.

Owner:SHANXI JINNAN IRON & STEEL GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com