Rotating plunger field energy converter

A rotary and converter technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., can solve the problem of wasting energy and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

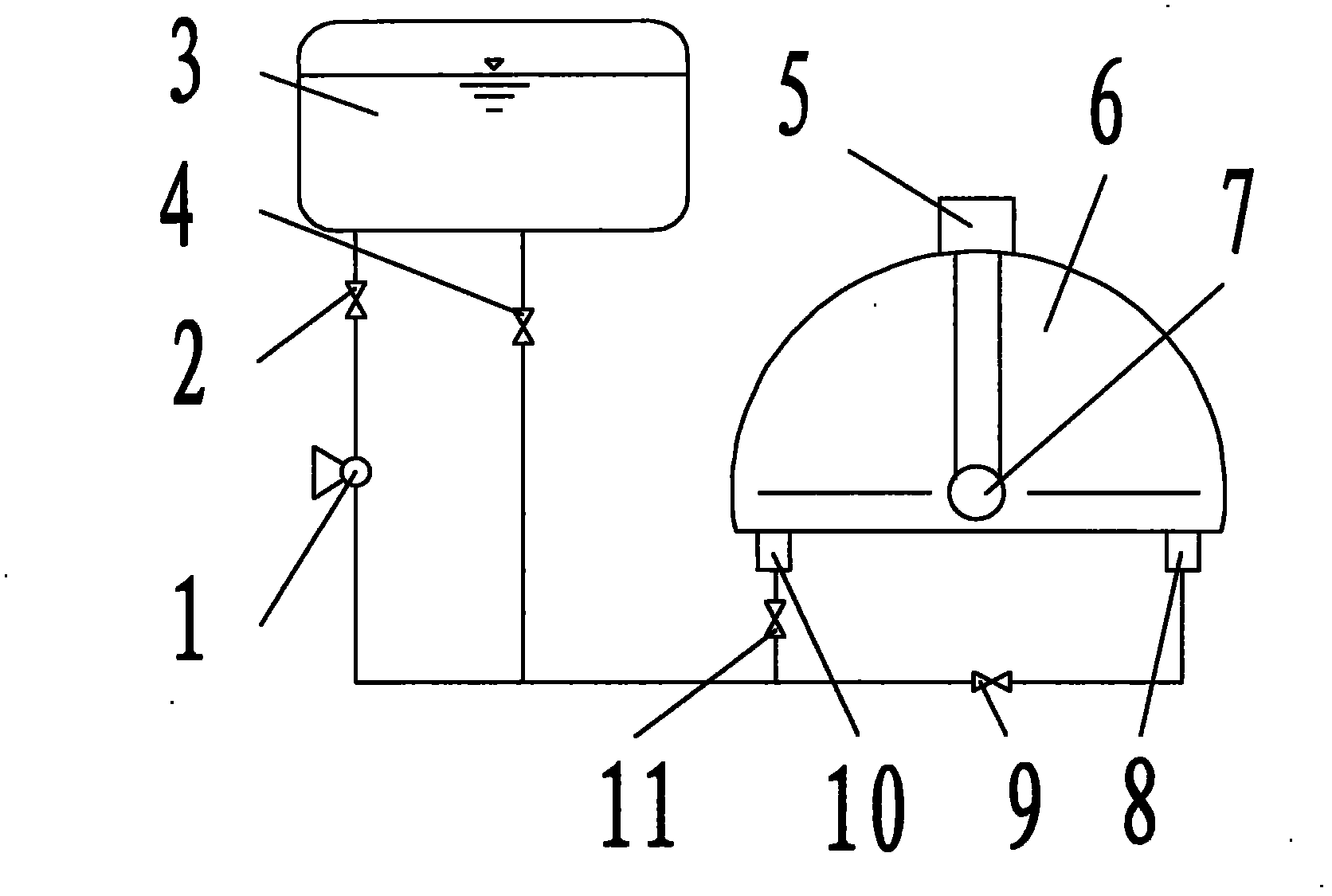

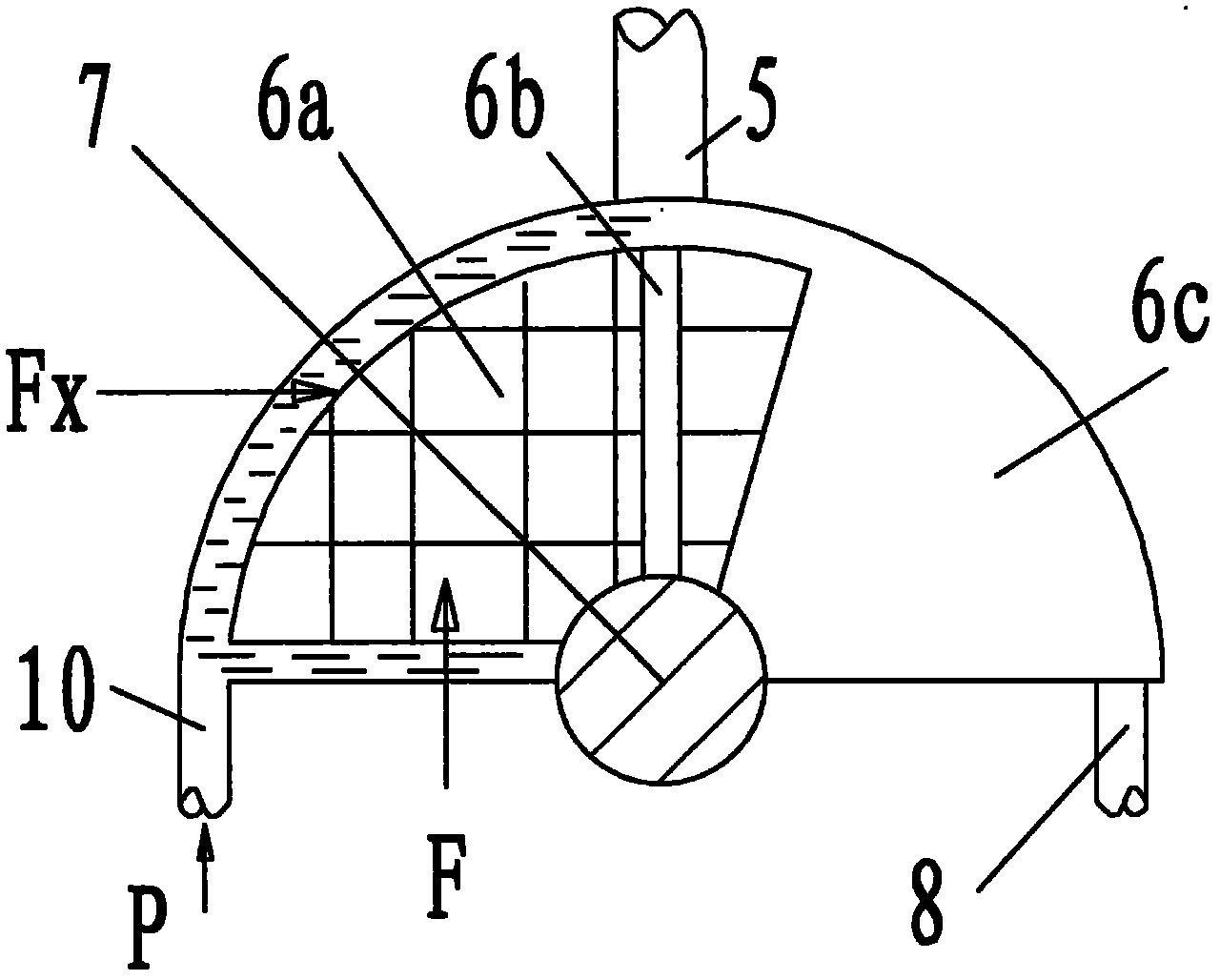

[0023] Embodiment 1: The equipment consists of a lifting pump 1, a lifting pump valve 2, a liquid storage tank 3, a liquid storage tank valve 4, an exhaust port 5, an internal energy generator 6, an output shaft 7, a first liquid inlet and outlet 8, a second The first inlet and outlet valve 9, the second inlet and outlet valve 10, and the second inlet and outlet valve 11, the outlet of the lift pump 1 is connected to the valve 2 of the lift pump, and the inlet is connected to the valve 4 of the liquid storage tank and the first inlet and outlet through pipelines The valve 9 and the liquid inlet and outlet valve 11 are connected, the valve 2 of the lift pump is connected with the liquid storage tank 3 through a pipeline, the lower part of the liquid storage tank 3 is connected with the valve 4 of the liquid storage tank, and the valve 4 of the liquid storage tank is connected with the lift pump 1 through a pipeline , the first liquid inlet and outlet valve 9, the second liquid i...

Embodiment 2

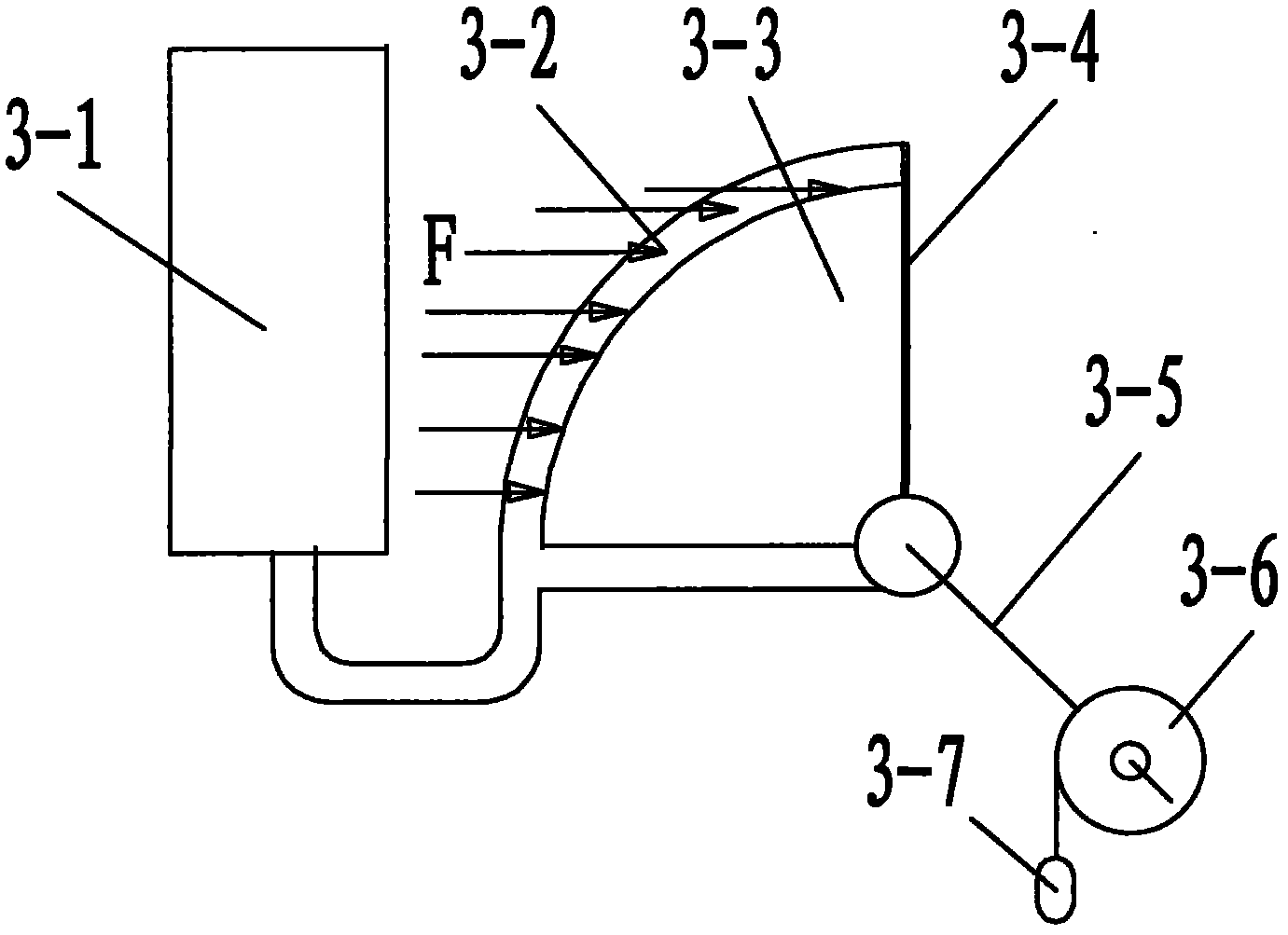

[0040] Embodiment 2: Experimental device and data analysis, including: liquid injector 3-1, housing 3-2, rotating floating body 3-3, seal 3-4, connecting shaft 3-5, torque disc 3-6 and weight 3-7.

[0041] Device composition:

[0042] 1. Shell: a 1\4 semicircle with a radius of 220mml and an inner hole width of 22mm, where the hole is located in the vertical direction. Material: ABS;

[0043] 2. Rotating floating body: a partial cylinder with a radius of 200mm and a thickness of 20.5mm and an angle of 100°. The diameter of the center shaft is 16mm, and the material is A3 steel.

[0044] 3. Sealing: The shaft seal is made of silica gel pad and cured by silica gel. Both sides are silicone tubes with an inner diameter of 4mm and an outer diameter of 6mm. Mercury is injected into the inside and embedded in the groove of the box.

[0045] 4. Moment plate: a pulley with a diameter of 250mm.

[0046] 5. Heavy hammer: ground balance weight, various specifications.

[0047]

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Division value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com