Vegetable cutter

A vegetable cutting machine and rack technology, applied in metal processing and other directions, can solve the problems of wasting energy, vegetable accumulation, complex structure, etc., and achieve the effects of energy saving, stable feeding and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

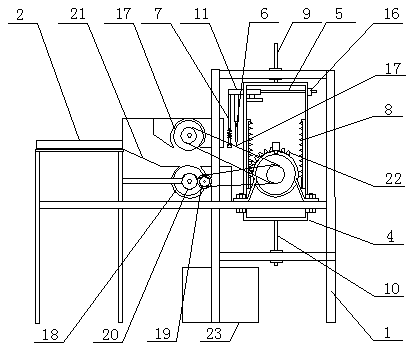

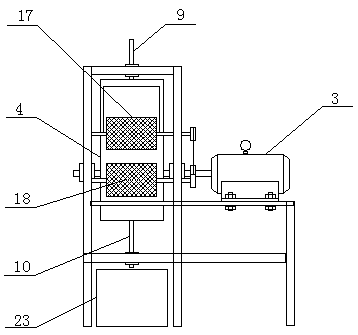

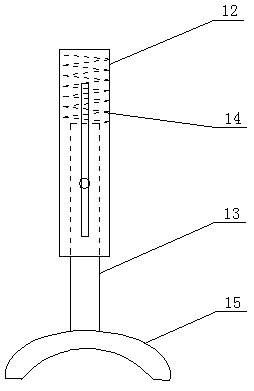

[0019] The vegetable cutting machine is composed of a frame 1, a knife frame, a vegetable receiving platform 2 and a motor 3. A knife frame is movable on the frame 1. The knife frame is composed of a mounting frame 4 and an adjusting screw rod 5. The mounting frame 4 is a rectangular frame. , the top of the mounting frame 4 is provided with an upper guide rod 9, the bottom of the mounting frame 4 is provided with a lower guide rod 10, and the upper guide rod 9 and the lower guide rod 10 are respectively slidingly connected with the frame 1; the inner surface of the mounting frame 4 is symmetrically installed with transmission Rack 8; the mounting frame 4 above the transmission rack 8 is equipped with a mounting seat 11 through an adjusting screw rod 5, the mounting seat 11 and the mounting frame 4 are slidingly connected, and one end of the mounting seat 11 extends to the outer end of the mounting frame 4 , Extending to the mounting seat 11 at the outer end of the mounting fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com