Preheating device for fuel oil engine

A preheating device and pre-starting technology, which is applied to the starting of engines, machines/engines, mechanical equipment, etc., can solve problems such as waste of energy, pollution of the environment, and difficulties in starting fuel engines, and achieve the effect of solving difficult starts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

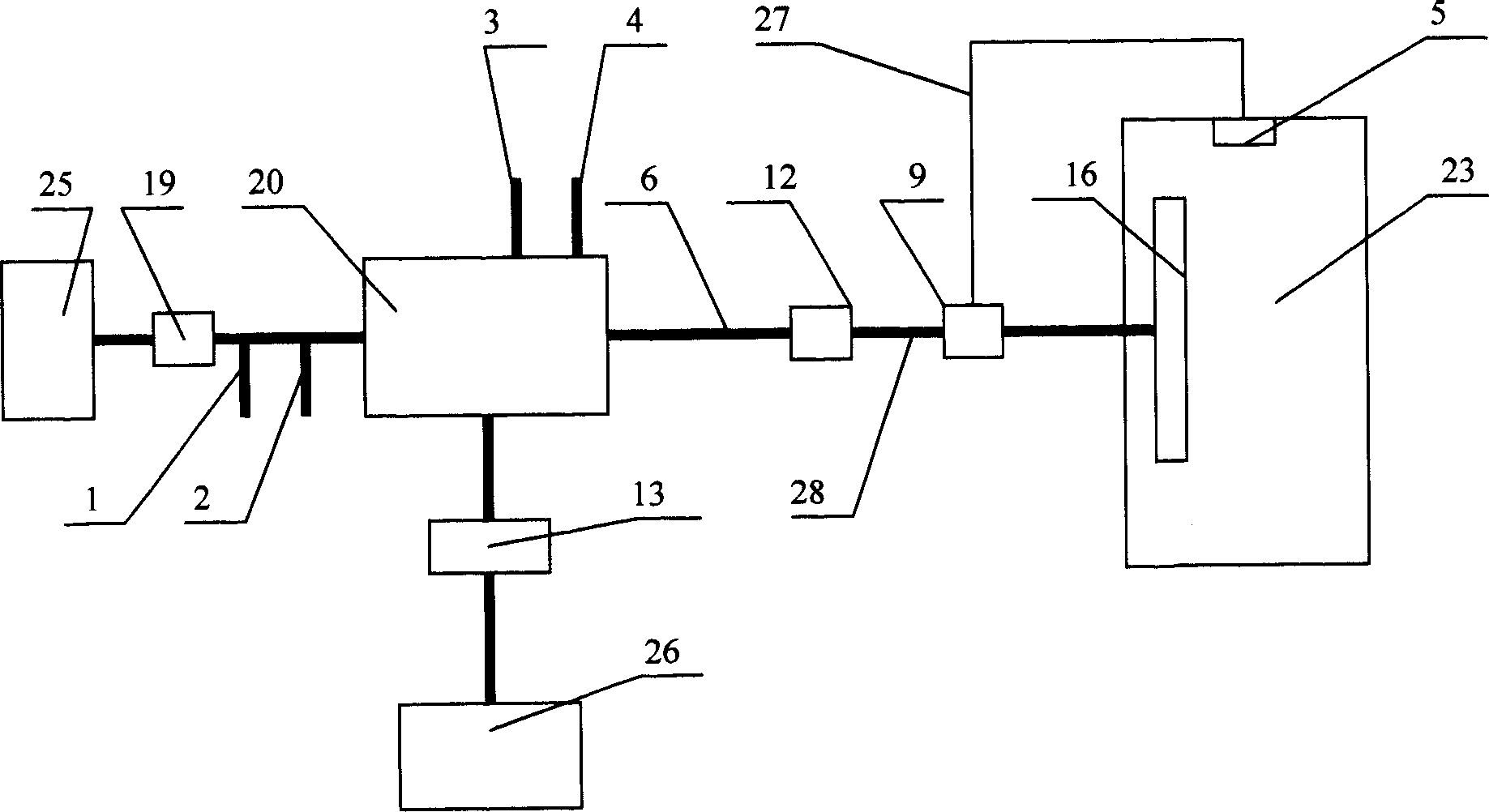

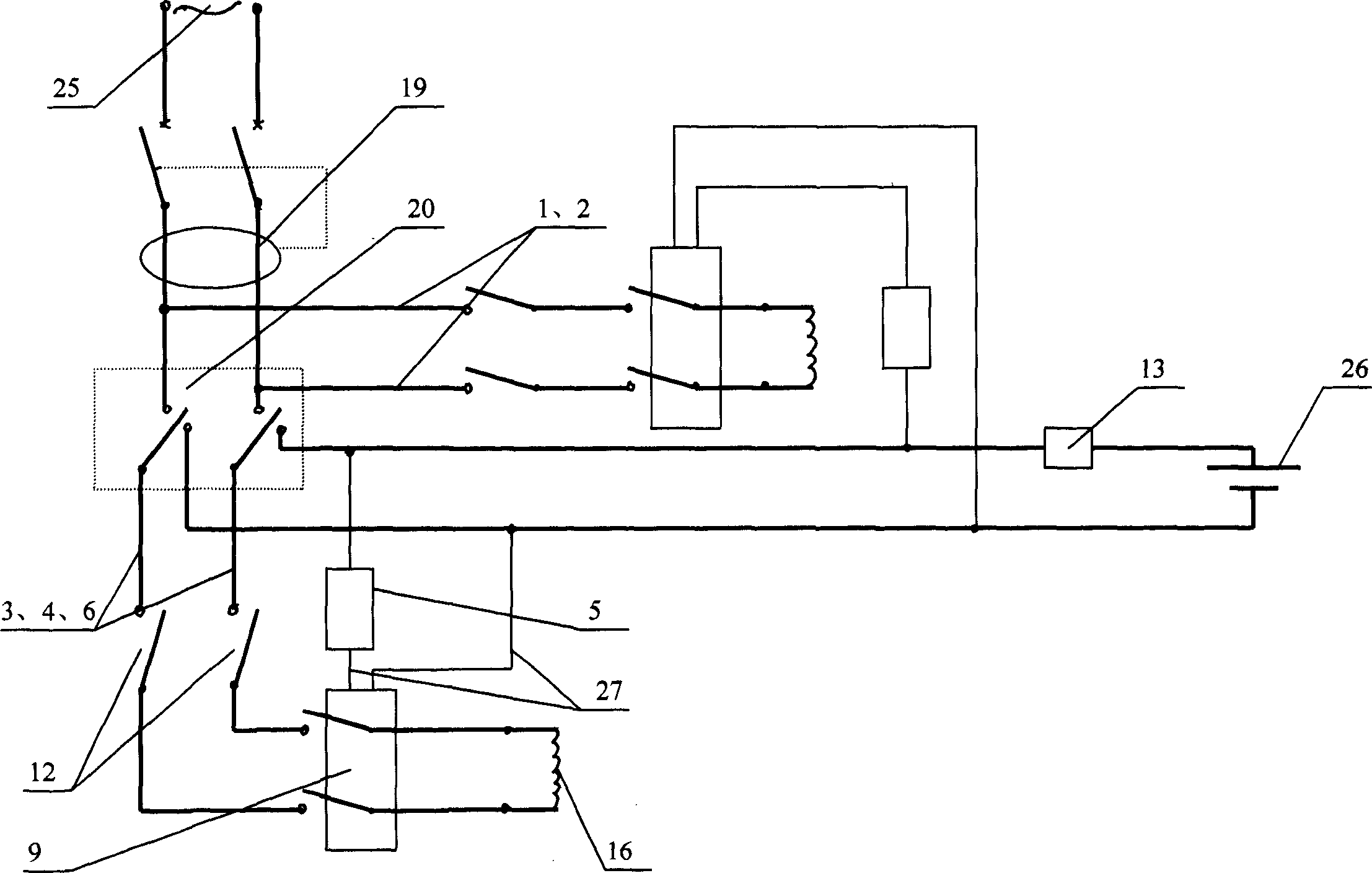

[0013] The working principle and automatic control of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0014] Figure 1 shows an embodiment of the invention. The preheating device before starting in this embodiment is composed of a heating element, a leakage protector, a switch, an AC / DC changeover switch, an external power supply, and the power supply of the equipment itself; On the heating parts such as oil device, engine body, oil pan, etc., induction devices are installed inside each heating part of the fuel engine; the induction devices are respectively connected to the temperature control device by wires, and then connected to their own power supply to form a preset Heat device automatic control circuit.

[0015] In practical applications, the number of heating elements can be set according to the needs of the situation, and the number of temperature sensing devices and temperature control devices can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com