Seamless anti-seismic abutment with separation type butt strap

A technology for belt separation and anti-seismic bridges, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of poor economy and high cost of anti-seismic abutments, achieve good horizontal deformation capacity, reduce the number of piles, and reduce the longitudinal load of abutments force reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

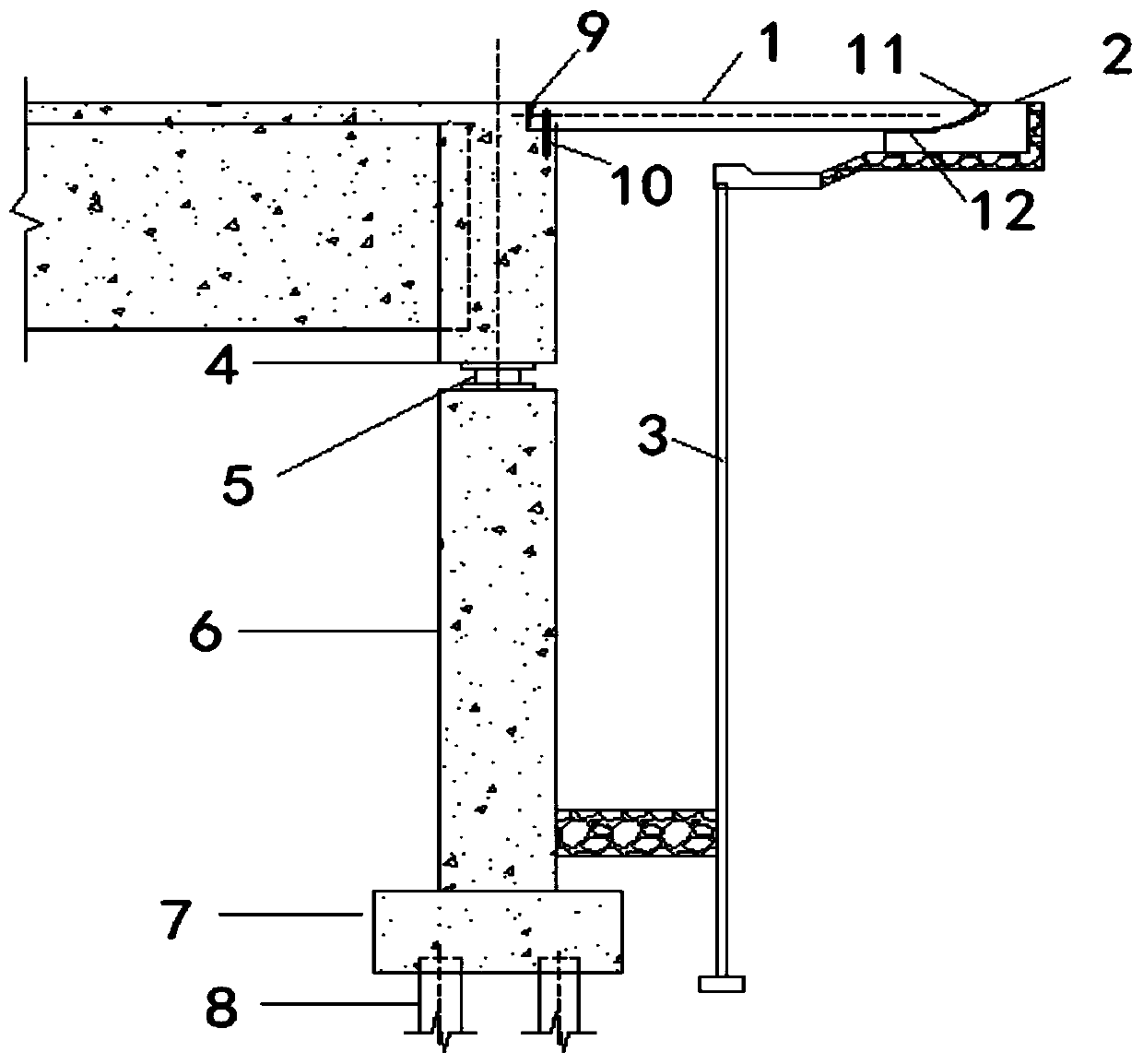

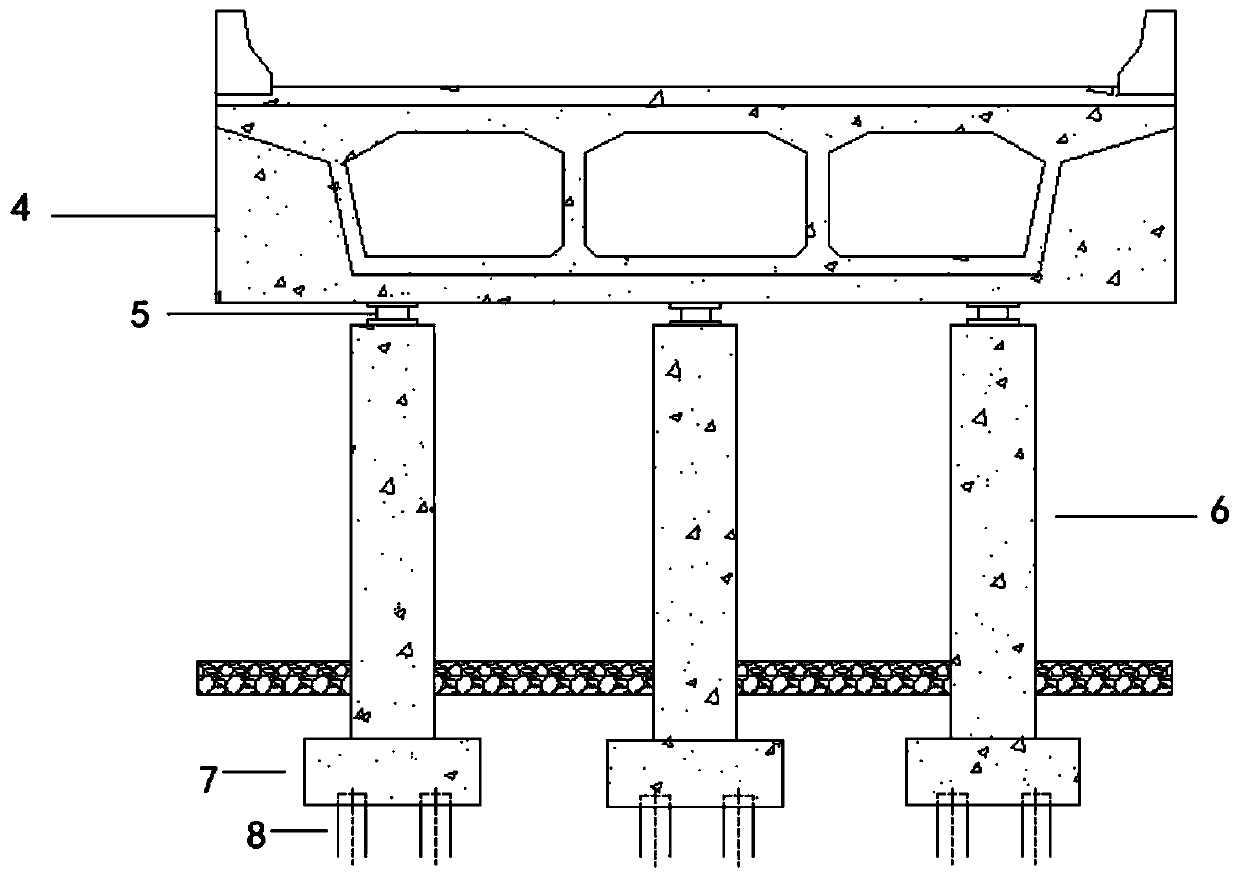

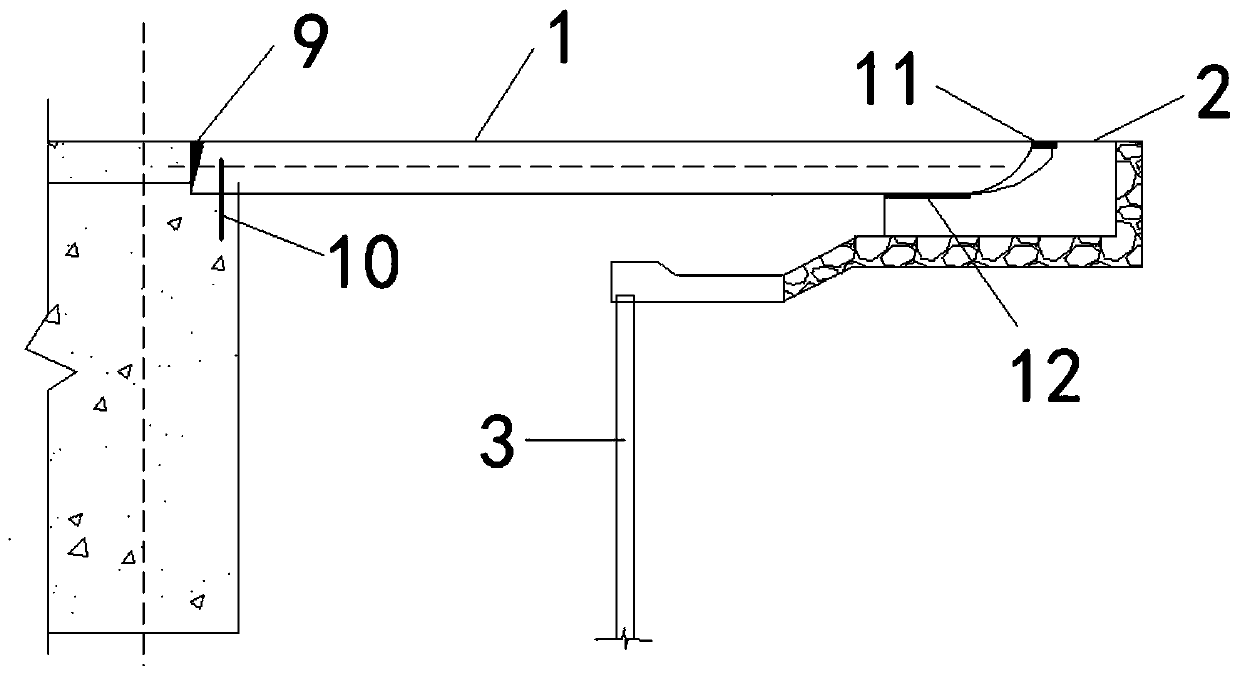

[0027] refer to Figure 1 ~ Figure 3 , a seamless anti-seismic abutment with separate strapping plates, including transverse girders 4, seismic isolation bearings 5, bridge piers 6, pile foundations 8, retaining walls 3, split strapping plates 1 and corbels 2, the The transverse partition beam 4 is located on the pier 6, the pier 6 is located on the pile foundation 8, and the corbel 2 is located behind the retaining wall 3; for example, the corbel 2 can be located on the gravel cushion behind the retaining wall 3 .

[0028] One end of the separated board 1 is placed on the corbel 2 , and the other end is seamlessly connected with the transverse beam 4 . Expansion joints are set between the separated lap board 1 and the corbel 2, and there is a sand sliding layer 12 at the vertical lap joint; the separated lap board 1 is seamlessly connected with the transverse beam 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com