Method for installing large-span front fulcrum guyed hanging baskets

An installation method and front fulcrum technology, which is applied in the field of large-span front fulcrum drag cable hanging basket installation, can solve problems such as potential safety hazards, uneven height of hanging points, and large force on local hanging points, so as to improve safety and reduce being The probability of wear and the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

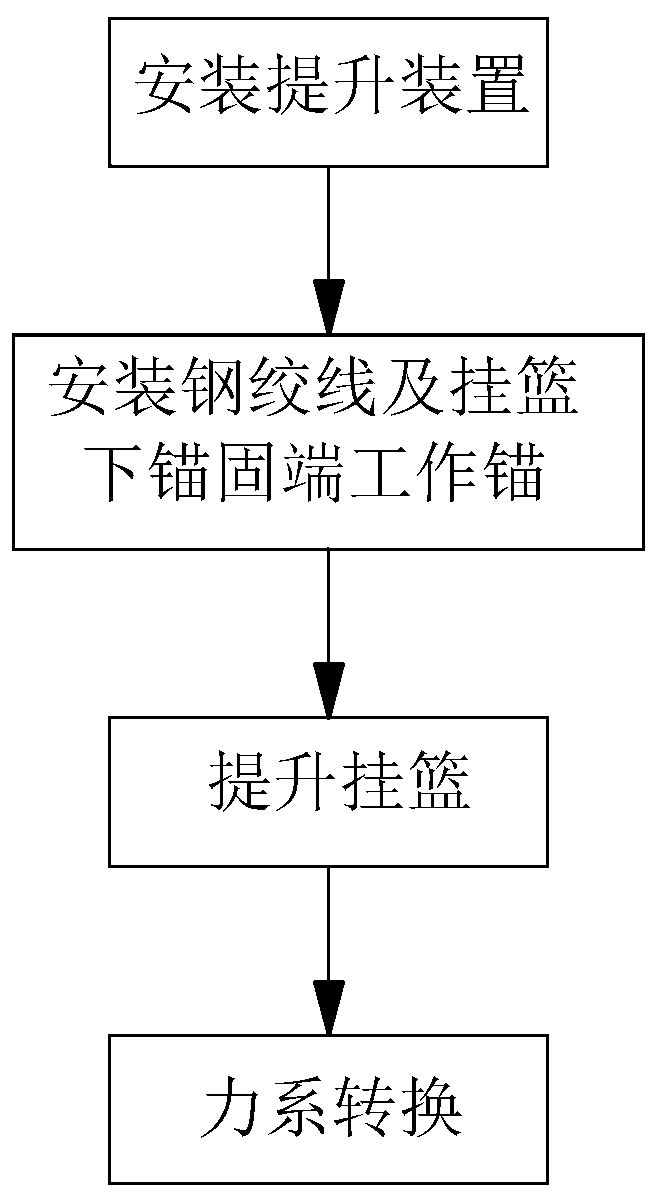

[0042] Step 1. Install the lifting device

[0043] 1) For the installation of the lifting system, first install the Bailey plate and the rear anchor rebar, and then install 8 sets of lifting devices, and the lifting devices are all controlled by the same power supply;

[0044] 2) Pay attention to the reinforcement of the lifting device on the Bailey sheet during the installation process. The double 45 I-beam in the lifting device is used as the distribution beam and the Bailey sheet to be reinforced with steel plates and bolts;

[0045] 3) Note that the jack and the reserved lifting hole are on the same vertical line to avoid abrasion of the steel strand during the lifting process.

[0046] Step 2. Install the steel strand and the working anchor at the anchor end of the hanging basket

[0047] 1) Install the equal-length and numbered steel strands that have been cut in advance from the top of the main beam;

[0048] 2) After the steel strand is installed in place, tighten th...

Embodiment 2

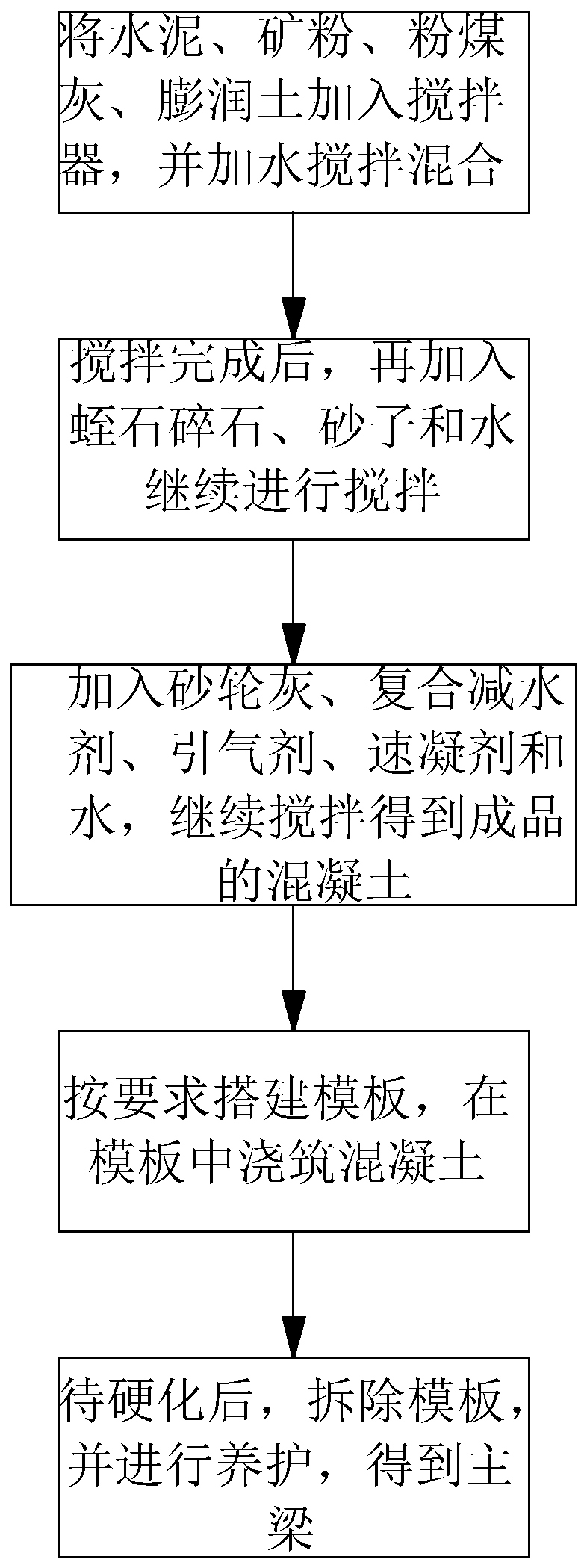

[0061] On the basis of embodiment one, the preparation method of the main girder of the present application comprises the following steps:

[0062] S1. Add 250Kg cement, 75Kg mineral powder, 60Kg fly ash, and 43Kg bentonite to the mixer, and add 1 / 3 of the total amount of water, that is, 67Kg water, and stir at a speed of 500rpm for 20 minutes;

[0063] S2. After the stirring is completed, add 60Kg of vermiculite gravel, 56Kg of sand and 2 / 5 of the total amount of water, that is, 80Kg of water, into the agitator, and stir at a speed of 300rpm, and the stirring time lasts for 30min;

[0064] S3. Add 56g of grinding wheel ash, 8g of composite water reducer, 3g of air-entraining agent, 3g of accelerator and the remaining water, that is, 53kg of water, into the mixer, and stir at a speed of 500rpm until the mixture is uniform to obtain the finished product concrete;

[0065] S4. Build the template according to the requirements of the main beam, and pour concrete into the template...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com