Gas heater

A gas heater and heater technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of low heat utilization efficiency and short service life, and improve heat utilization efficiency and service life. , the effect of excellent temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

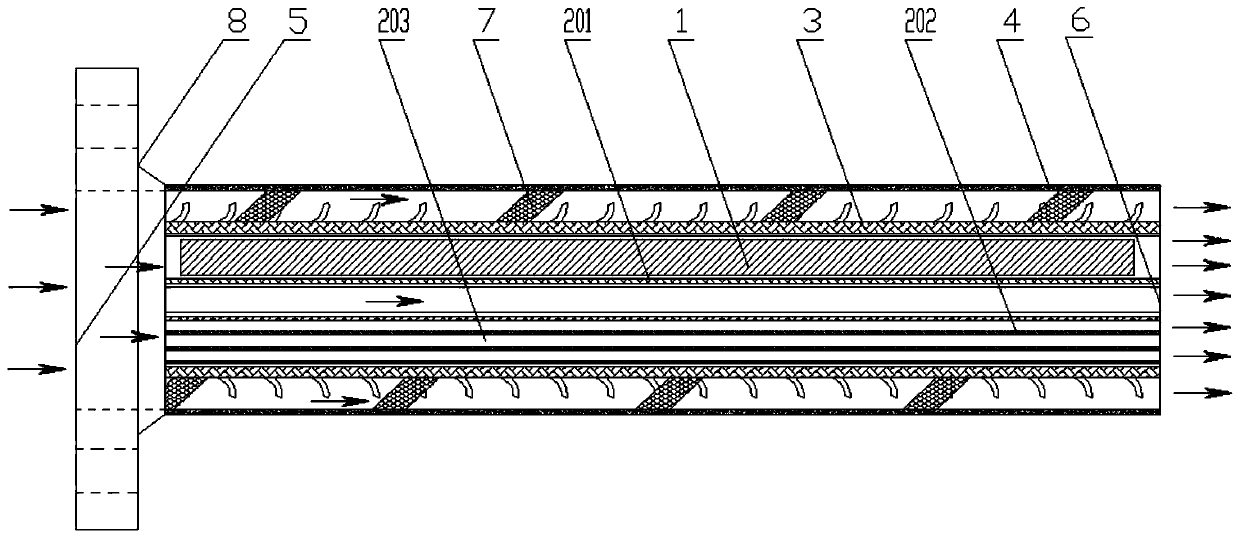

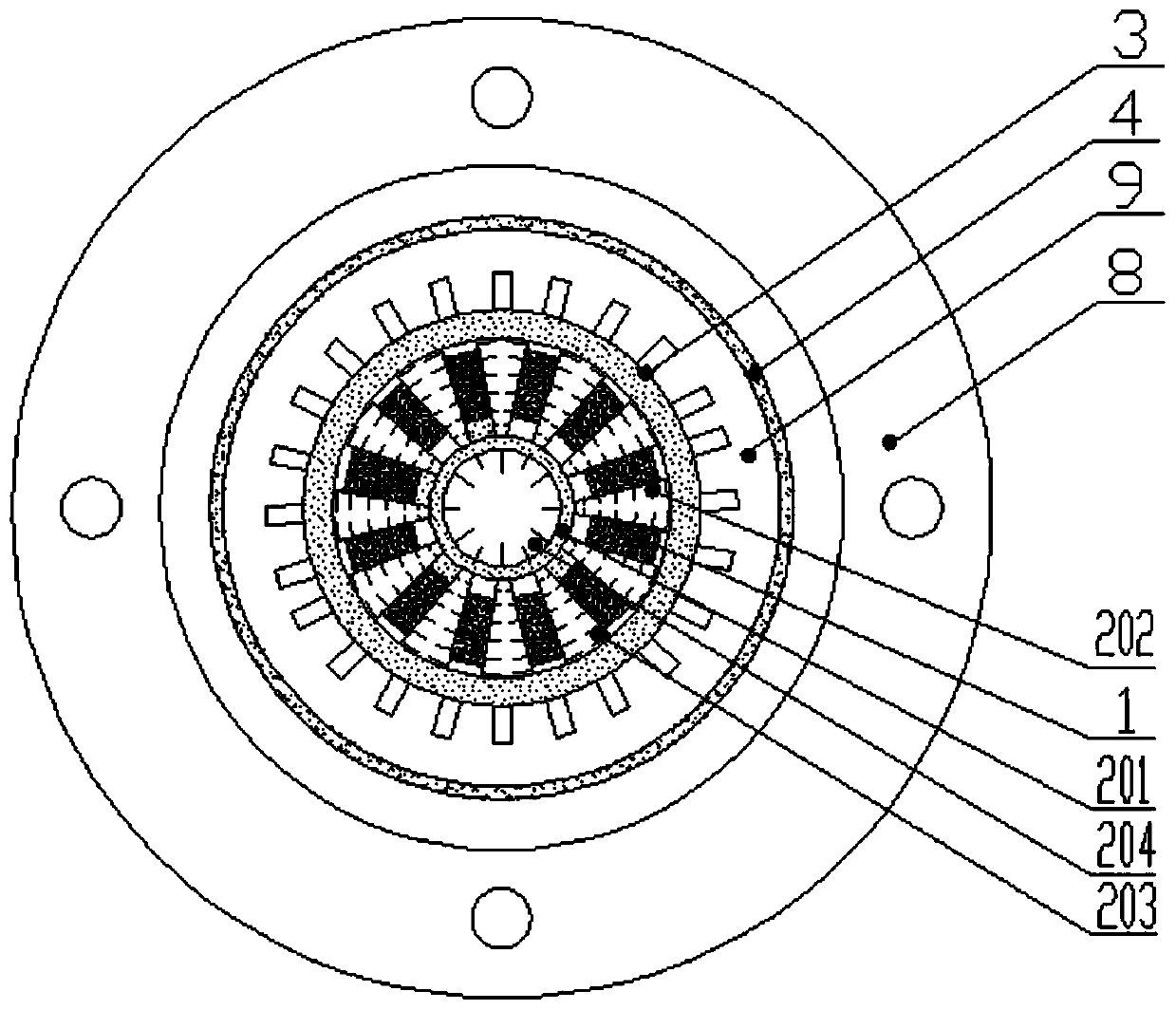

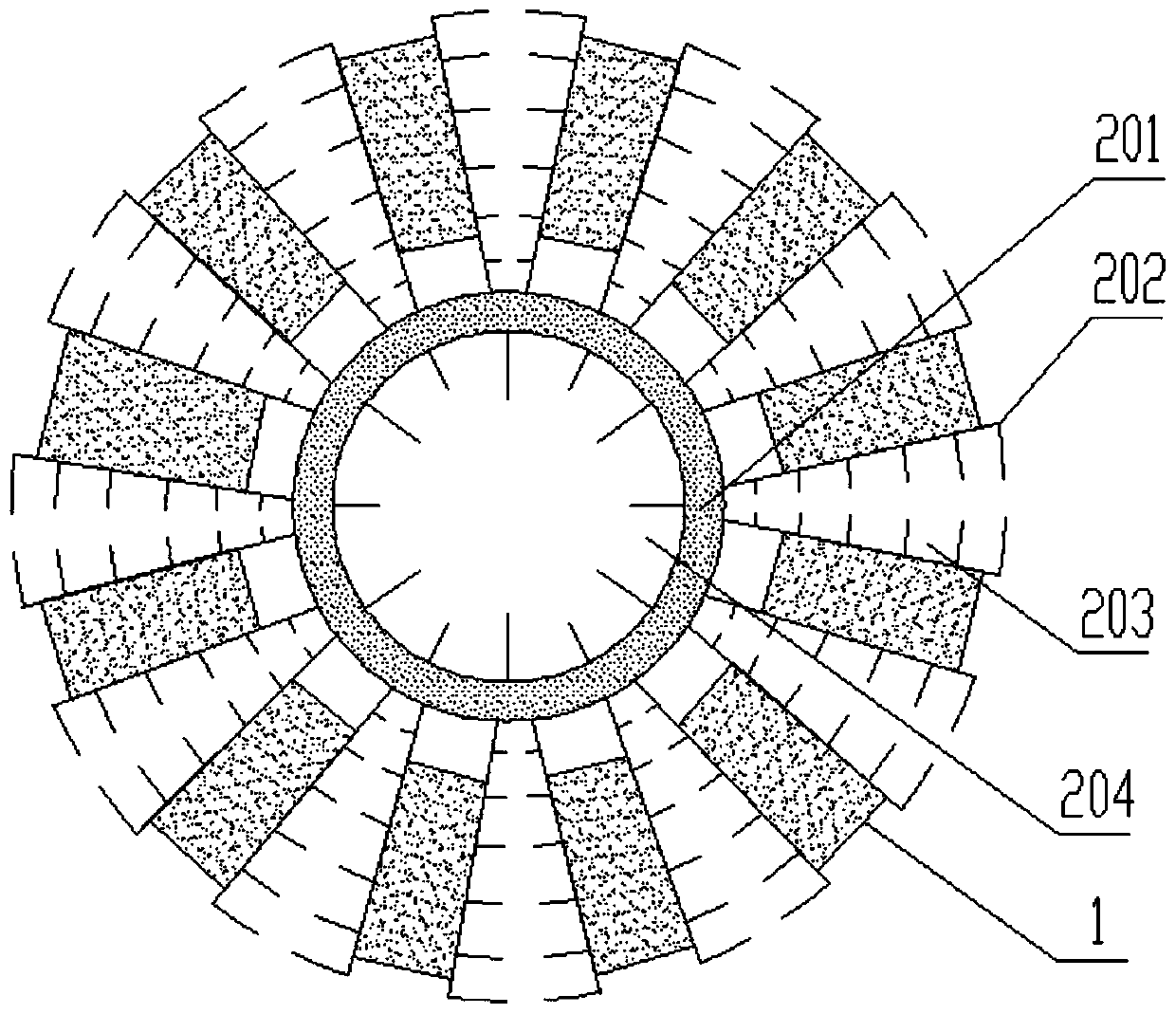

[0020] A gas heater such as figure 1 , figure 2 and image 3 As shown, it includes a PTC heating core 1 with a heating power of 3000W and a heat-conducting structure for assembling the PTC heating core 1. The PTC heating core 1 can be connected to a power supply through a wire, and the PTC heating core 1 and the heat-conducting structure are arranged axially. In the three-dimensional finned heat exchange tube 3, the inner wall of the three-dimensional finned heat exchange tube 3 and the outer wall of the heat conduction structure cooperate in an interference fit, the three-dimensional finned heat exchange tube 3 is axially arranged in the outer cylinder 4, and the cooling medium passes through The air inlet 5 enters the outer cylinder 4, and one end of the air inlet 5 has a flange 8 for connecting the fan flange or other air introduction equipment, and realizes heat exchange with the three-dimensional finned heat exchange tube 3 and the heat conduction structure, and the obt...

Embodiment 2

[0034] A gas heater, referring to Example 1, wherein the pitch of the spiral body 7 is 150mm, and the three-dimensional finned heat exchange tube 3, the cylinder body 201, and the rib body 202 are all made of 304 stainless steel.

Embodiment 3

[0036] A gas heater, referring to Example 1, wherein the pitch of the spiral body 7 is 350 mm, the three-dimensional fin heat exchange tube 3 and the rib body 202 are made of 304 stainless steel, and the cylinder body 201 is an ordinary carbon steel pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com