Thickness measurement platform based on laser beam emission

A technology of thickness measurement and laser emission, which is applied in the field of thickness measurement platform based on laser beam emission, which can solve the problem of difficulty in measuring the surface smoothness of glass cubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

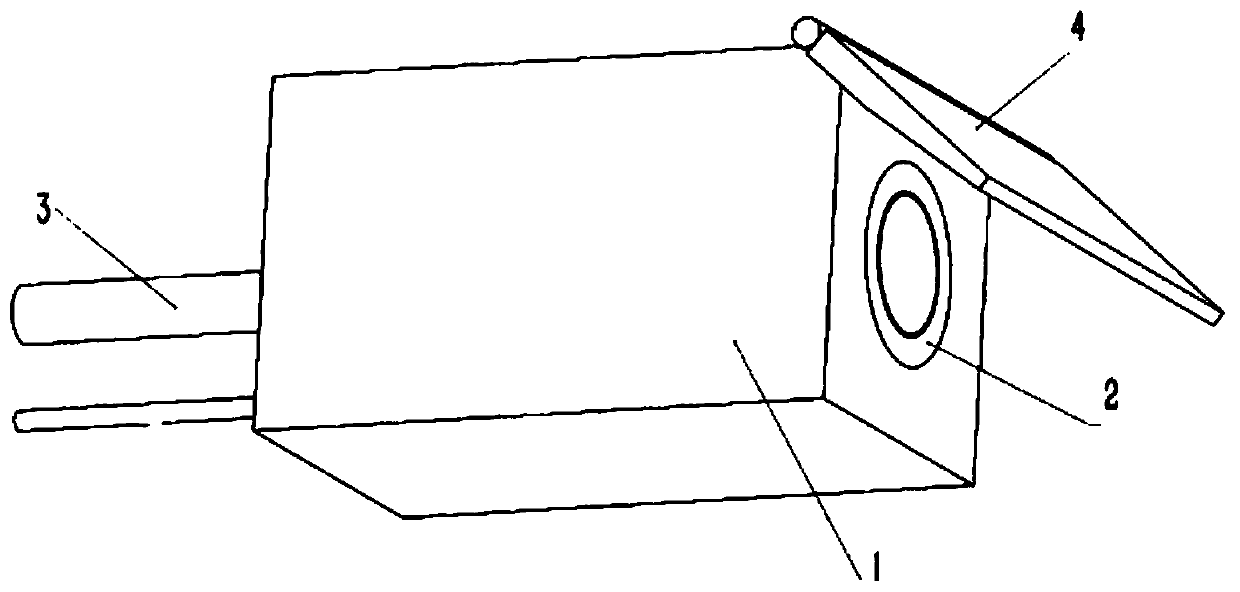

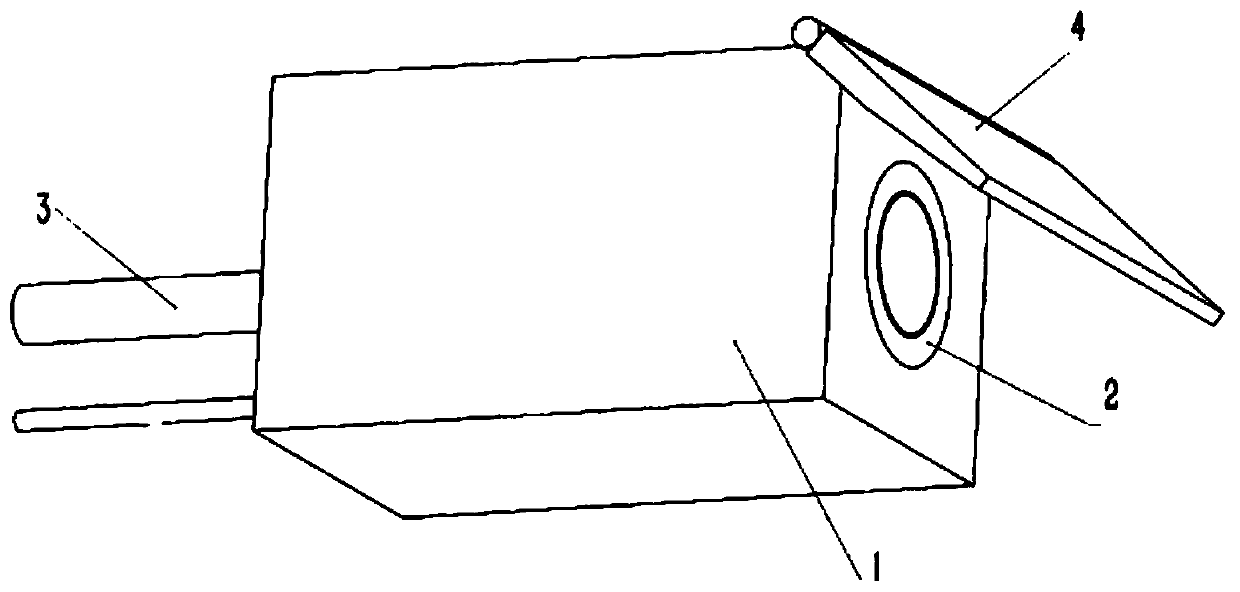

[0020] Embodiments of the thickness measurement platform based on laser beam emission of the present invention will be described in detail below with reference to the accompanying drawings.

[0021] The glass thickness measurement in the prior art has the following basic features: 1. The laser non-contact measurement does not damage the workpiece. 2. High data acquisition frequency ensures high efficiency measurement. 3. The accuracy of the laser probe is <0.5um, ensuring high-precision measurement. 4. The appearance design is beautiful, the interior is compact, and the volume is small. 5. Modular design, more convenient for assembly and maintenance. 6. Screw drive, low noise, accurate positioning, and more stable operation. 7. Highly integrated circuit design, intelligent judgment of fault points.

[0022] In order to overcome the above shortcomings, the present invention builds a thickness measurement platform based on laser beam emission, which can effectively solve the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com