An ultrasonic liquid level detection method

A liquid level detection and ultrasonic technology, which is applied in the field of ultrasonic liquid level gauge and its liquid level detection, can solve the problems of low measurement accuracy, complex structure and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

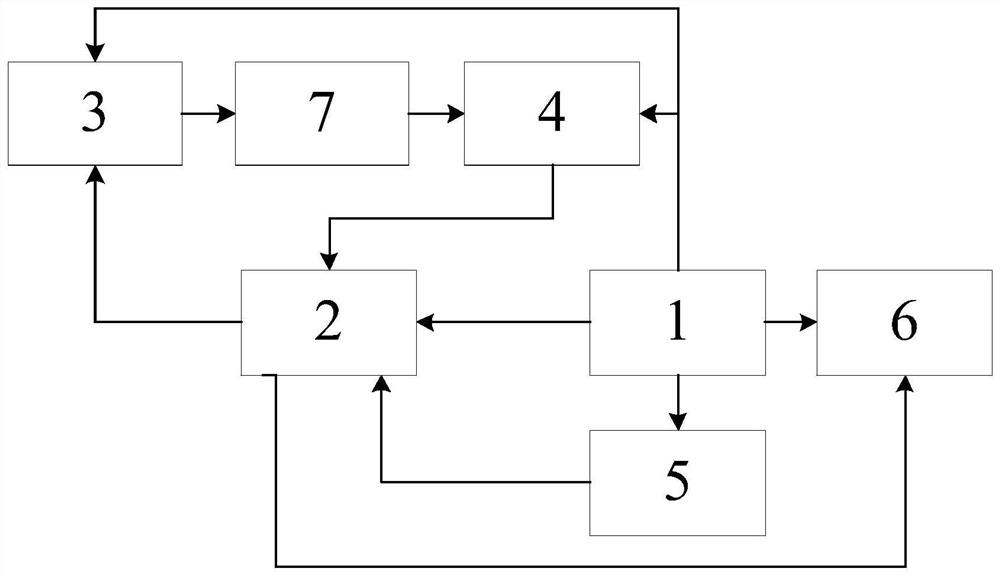

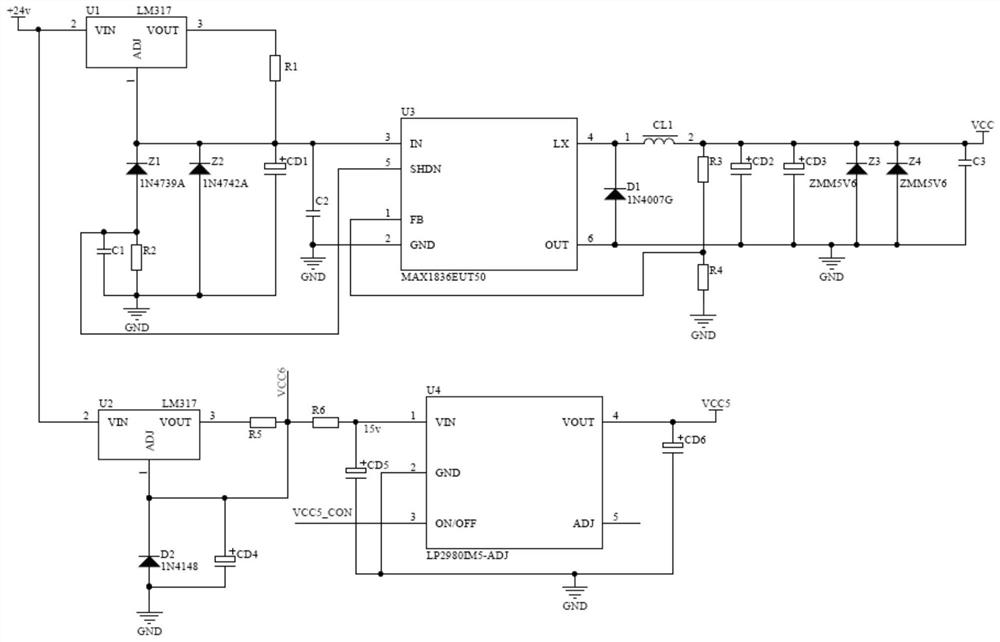

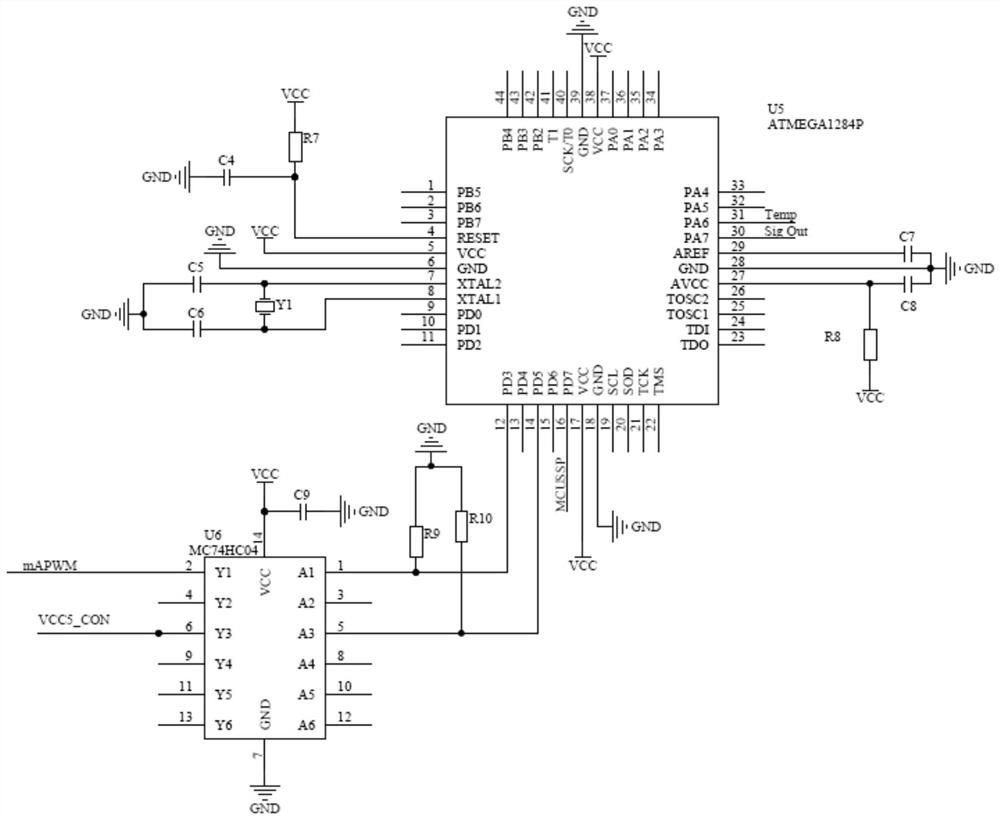

[0036] Such as figure 1 As shown, an ultrasonic liquid level gauge includes a power supply module 1 , a control module 2 , a sensor, an ultrasonic transmitting module 3 , an ultrasonic receiving module 4 , a temperature compensation module 5 , an output module 6 and piezoelectric ceramics 7 . The power module 1 converts the externally connected 24V voltage into the control module 2, ultrasonic transmitting module 3, ultrasonic receiving module 4, The temperature compensation module 5 and the output module 6 supply power. The control module 2 transmits the ultrasonic control signal to the ultrasonic transmitting module through the single-chip microcomputer, thereby controlling the transmitting frequency of the ultrasonic transmitting module; The 300V high-voltage alternating current excites the piezoelectric ceramic 7 to generate ultrasonic waves. The ultrasonic receiving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com