Underwater concrete sampler and sampling method

A technology of underwater concrete and sampler, which is applied in the direction of sampling device, etc., to achieve the effect of simple sampling operation and precise structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

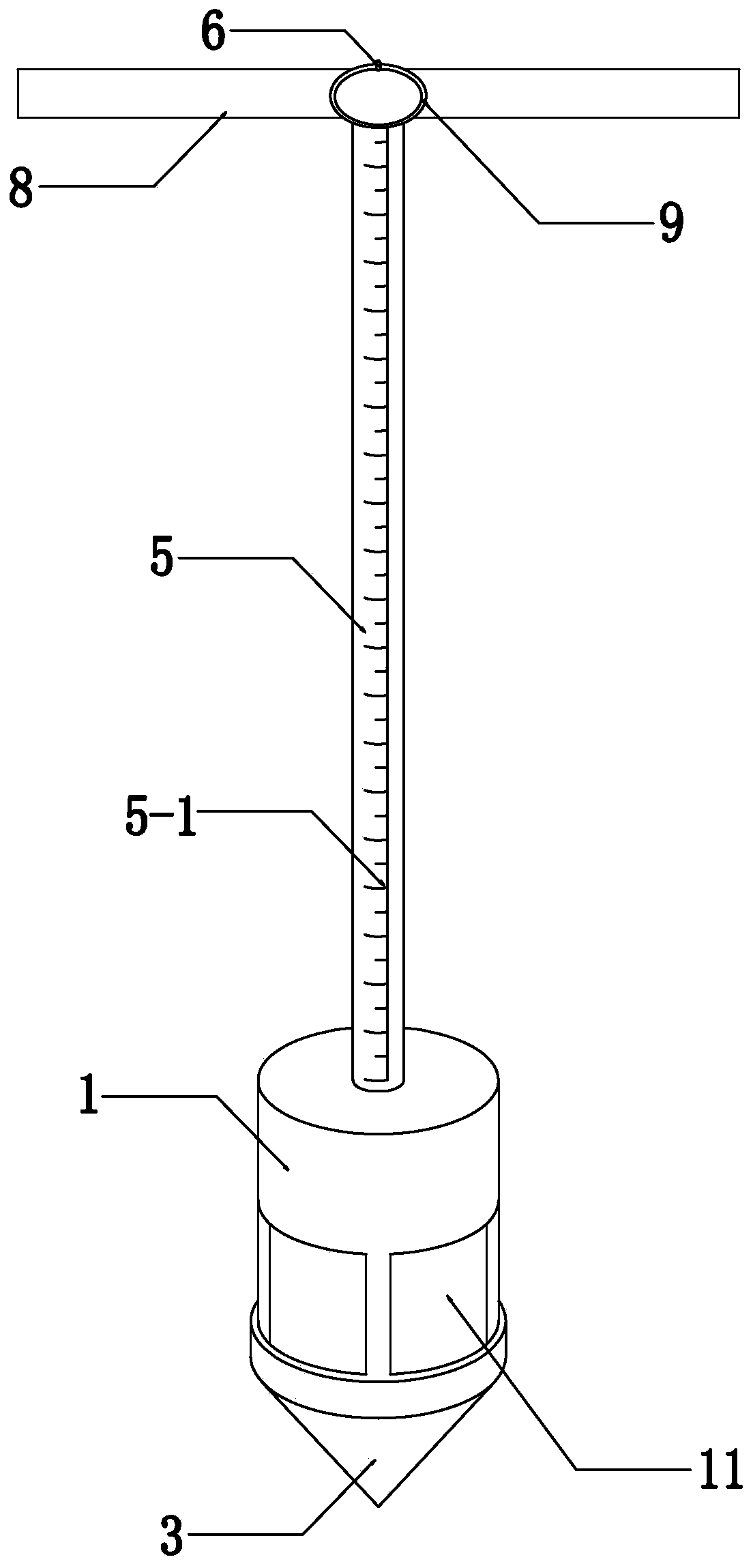

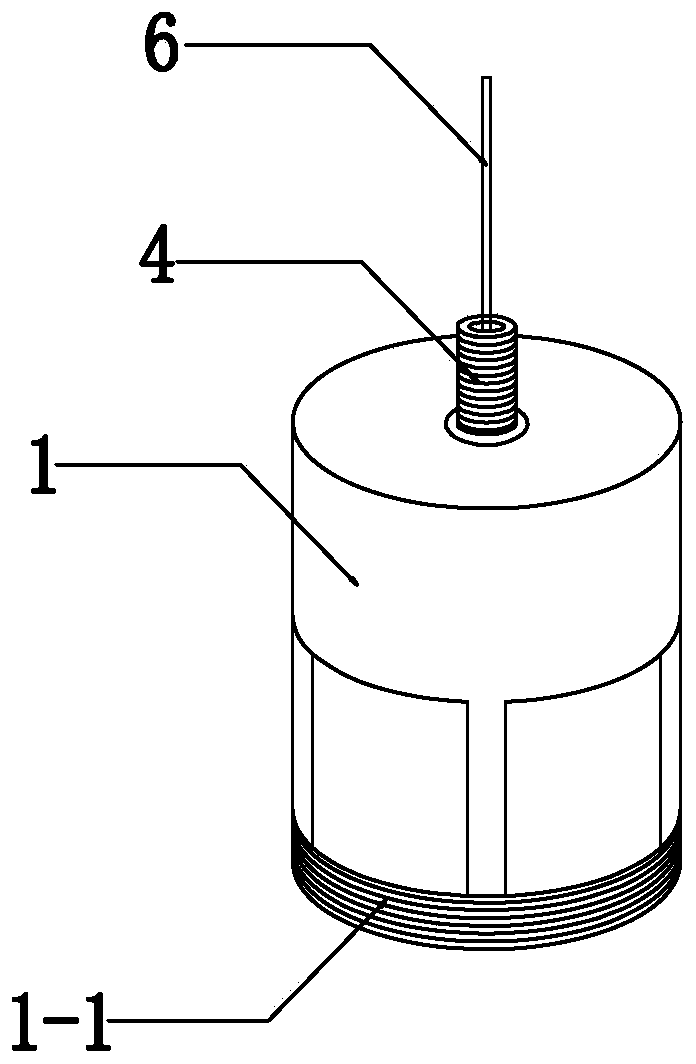

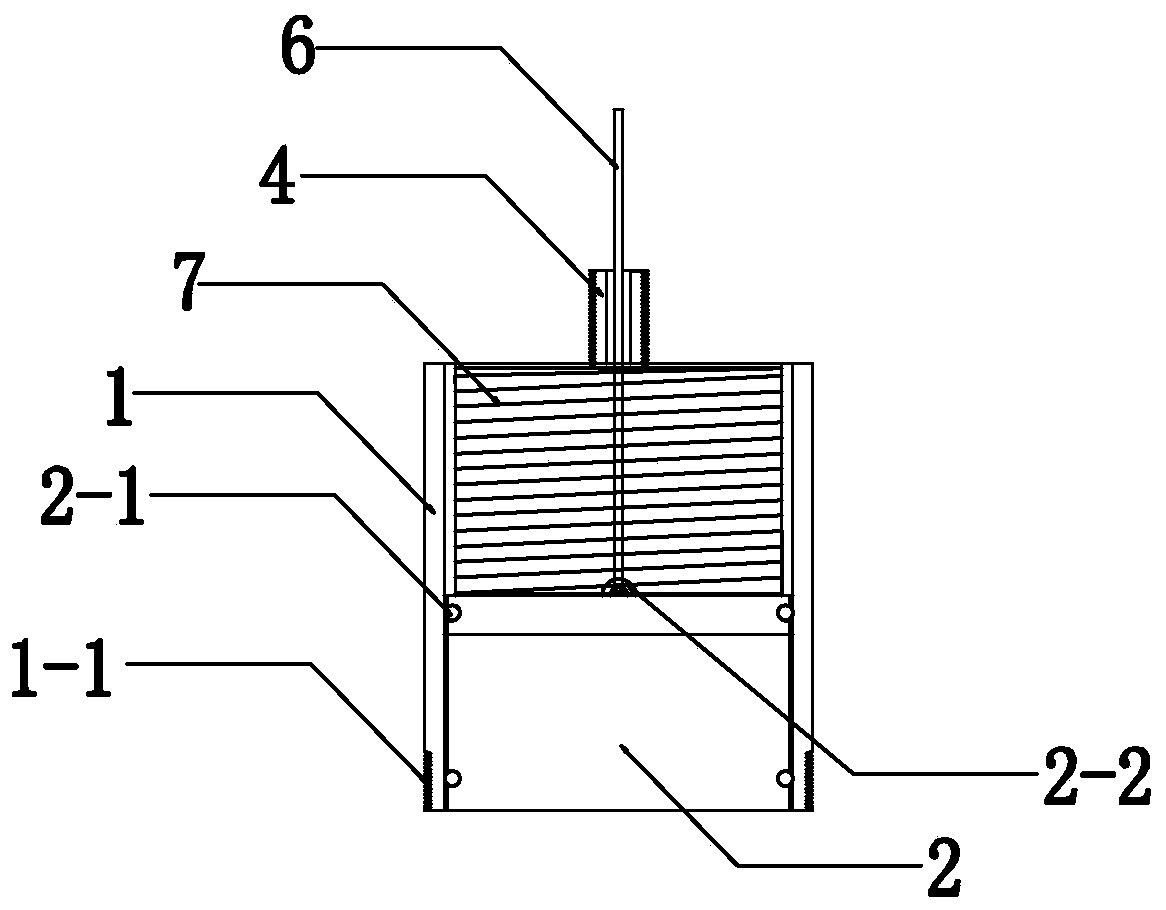

[0034] Example: such as Figure 1-5 As shown, an underwater concrete sampler and sampling method include a sampling system and a manipulation rope 6; the sampling system includes a sampling outer cylinder 1, a sampling inner cylinder 2 and a base 3; the base 3 is detachably connected to the outer cylinder 1 Bottom; at least one sampling port 11 is opened on the outer wall of the sampling outer cylinder 1, the sampling inner cylinder 2 is set in the outer cylinder 1, and the control rope 6 drives the sampling inner cylinder 2 to move up and down along the inner wall of the sampling outer cylinder 1, The sampling port 11 is opened or closed; the sampling outer cylinder 1 is cylindrical, and the upper opening is closed. The center of the top surface of the sampling outer cylinder 1 is provided with a connecting hole, and the sampling outer cylinder 1 is welded with a hollow hole corresponding to the connecting hole. Shaped connecting pipe 4, the outside of the connecting pipe 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com