Ultrasonic thickness measurement method for metal composite material and application of interlayer interface in ultrasonic thickness measurement

A metal composite material and composite material technology, applied in the ultrasonic thickness measurement method of metal composite materials and the application field of interlayer interface in ultrasonic thickness measurement, can solve the problems of inability to accurately measure the overall thickness of metal composite materials, and the thickness cannot be measured. Achieve the effect of solving the problem of ineffective use, convenient and reliable measurement, and avoiding sound velocity errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

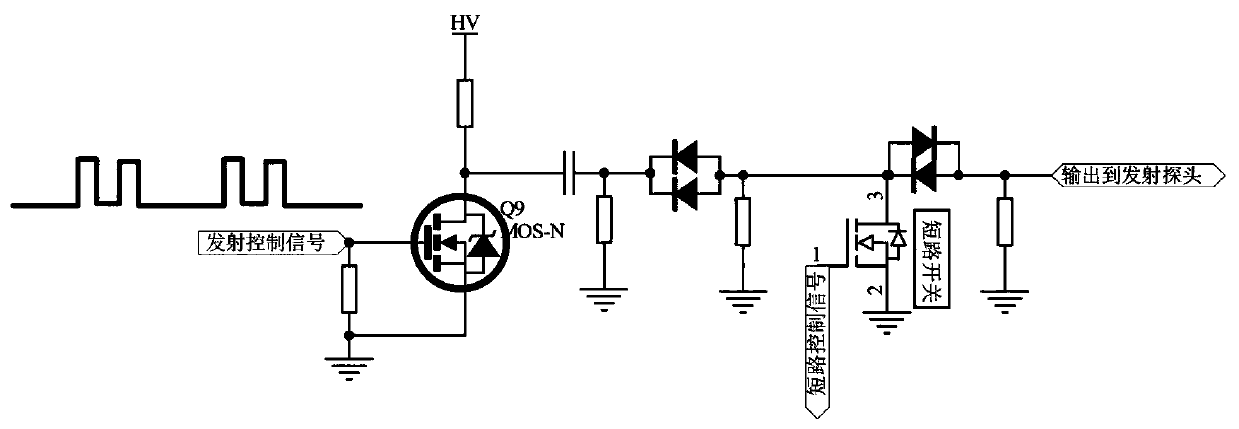

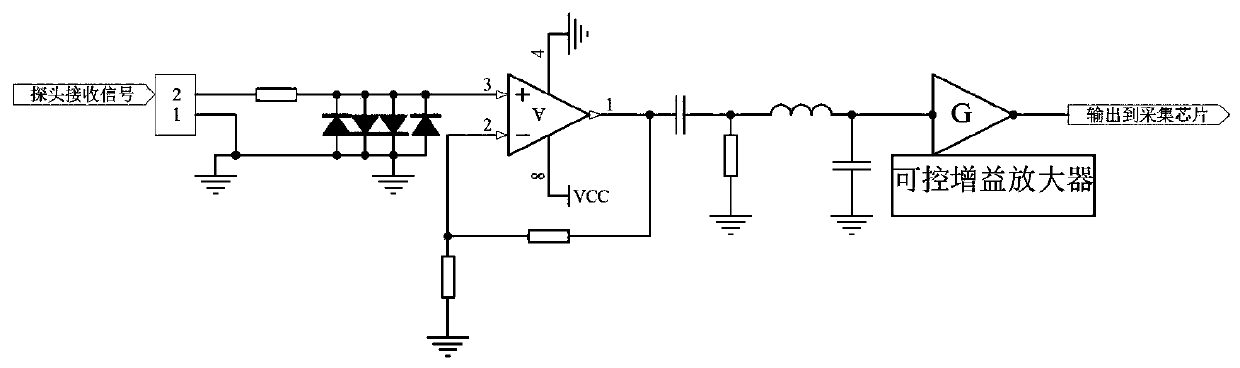

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0042] like Figures 1 to 10 As shown, an ultrasonic thickness measurement method for metal composite materials uses dust, rust, dirt and other interface substances formed during the explosive composite process as the interlayer interface of two metal materials. Use the reflected wave of the ultrasonic wave at the interface between layers to record the propagation time of the ultrasonic wave in the single-layer material, and the sound velocity of the ultrasonic wave in each material to calculate the thickness of each material, and calculate the overall thickness of the composite material according to the thickness of each layer of material. It solves the problem that the reflected wave at the interface between layers cannot be effectively used. Using the interlayer interface reflection wave as the calculation basis for accurate measurement, the thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com