Full-automatic cast welding machine for storage battery

A fully automatic, casting welding machine technology, applied in the field of battery automatic processing machinery, can solve the problems of inability to process batteries, achieve the effects of simplifying the structure, improving processing efficiency, and avoiding false welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

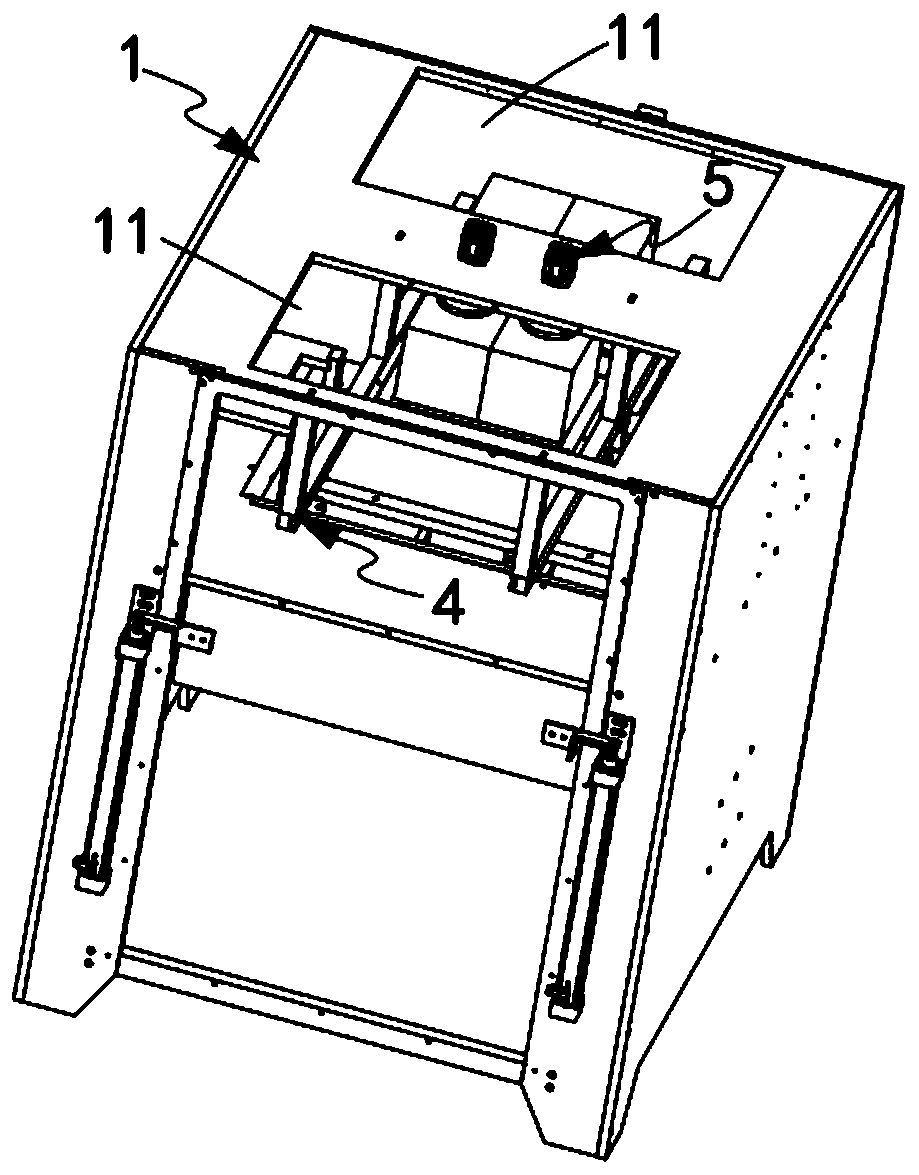

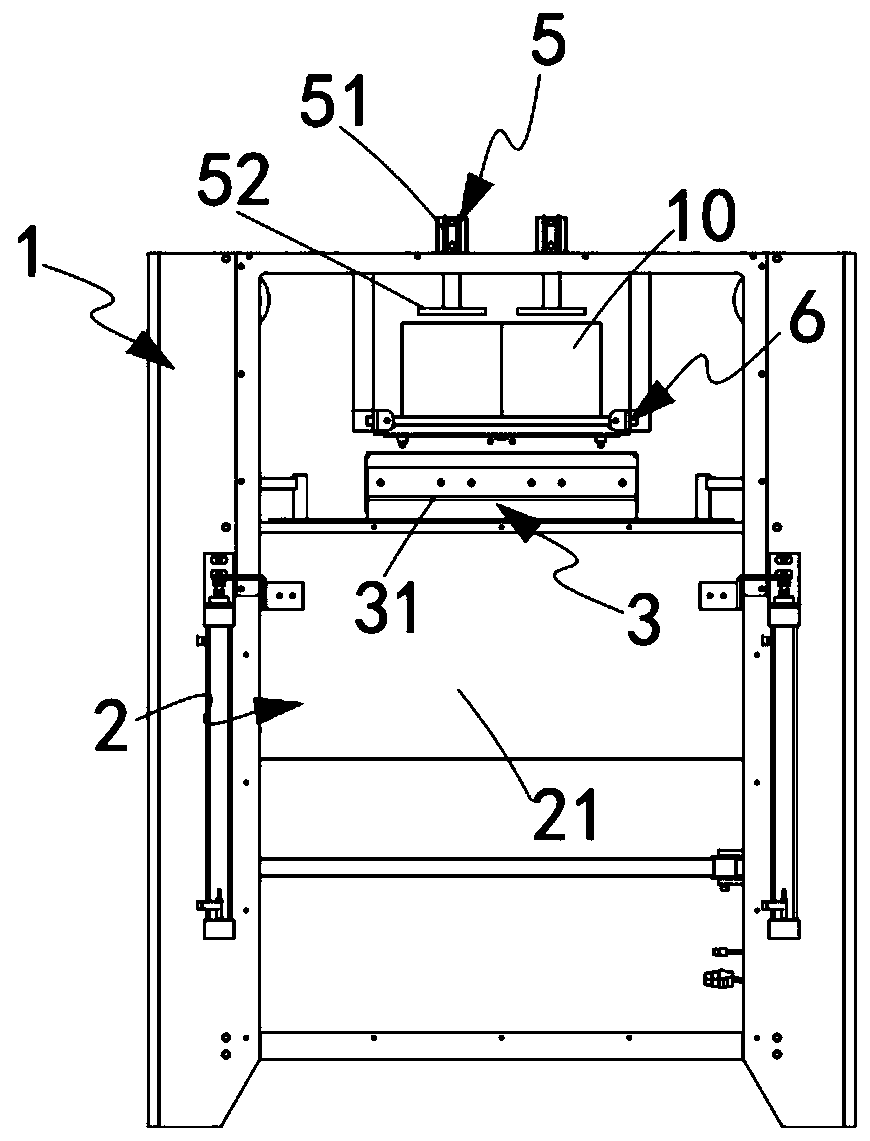

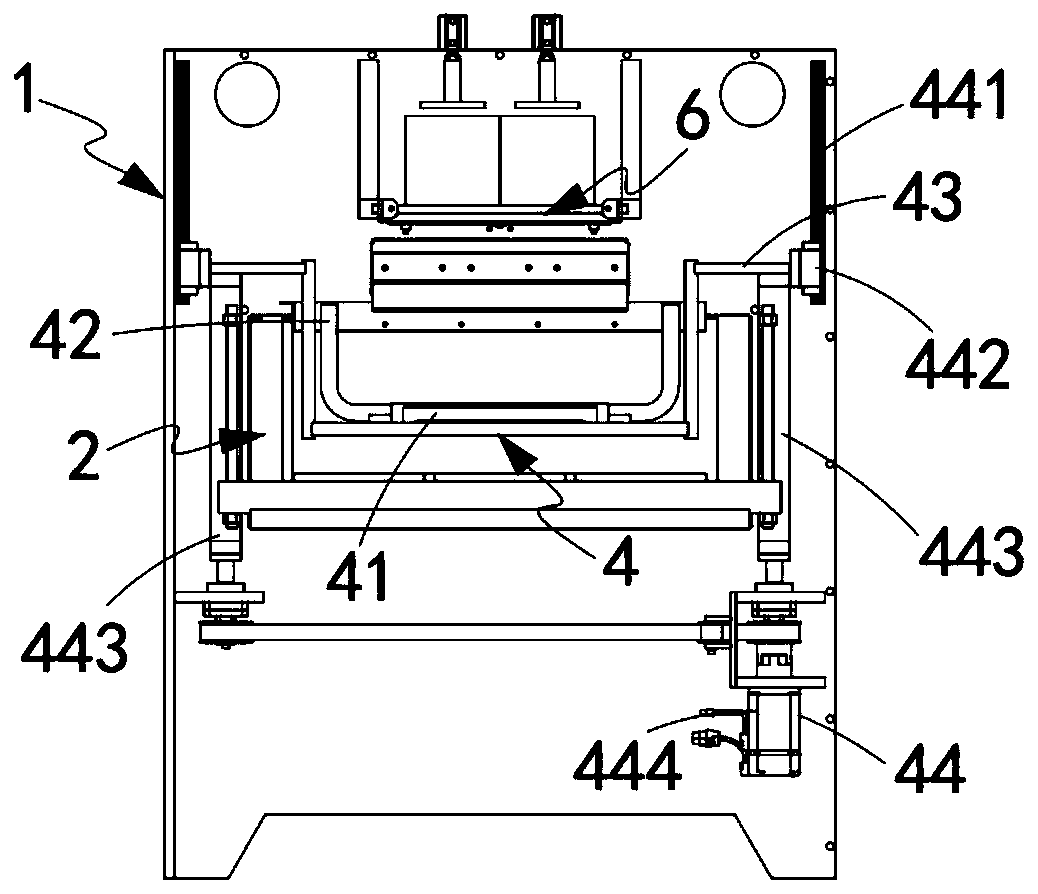

[0051] Such as Figure 1 to Figure 4 As shown, a fully automatic casting and welding machine for batteries includes a casing 1, and the casing 1 is respectively provided with a lead melting mechanism 2 and a lead scraping mechanism 3, and the lead scraping mechanism 3 is arranged above the lead melting mechanism 2, The lead-melting mechanism 2 is soaked with a casting and welding mechanism 4, and the casting and welding mechanism 4 can move up and down in the vertical direction, and is characterized in that:

[0052] The top of the housing 1 is provided with a symmetrically arranged feeding port 11, and a positioning mechanism 5 is arranged at the middle position of the symmetrically arranged feeding port 11, and the positioning mechanism 5 is arranged facing the casting and welding mechanism 4, and the The below of the feed port 11 is provided with a switching mechanism 6, the switch mechanism 6 is located above the lead scraping mechanism 3, and it includes a tray 61 slidabl...

Embodiment approach

[0056] Such as Figure 10 As shown, as an effective implementation, the lead melting mechanism 2 includes a lead pot 21 with an opening upward and a heating element 22 arranged on the lead pot 21 to heat it, and the lead pot 21 contains There is hot molten lead.

[0057] It should be noted that the lead liquid in the lead pot 21 needs to be kept at a constant temperature, and the lead pot 21 is heated and kept warm by the heating element 22, wherein the heating element 22 is an electromagnetic induction heating element.

[0058] Such as Figure 7 and Figure 8 As shown, as a preferred embodiment, the lead scraping mechanism 3 includes a vertical scraper 31 and a scraper driving member 32 that drives the scraper 31 to move along the direction in which the feed port 11 is set. The scraper driving member 32 is mounted on the housing 1 .

[0059] It should be noted that the scraper driver 32 drives the scraper 31 to move horizontally, and the mold 41 in the casting welding mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com