Bactericidal breathable film and its preparation method and application

A breathable film and film technology, applied in bandages, absorbent pads, medical science, etc., can solve problems such as difficult application of medical supplies, and achieve the effect of low cost, simple preparation process, and strong elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

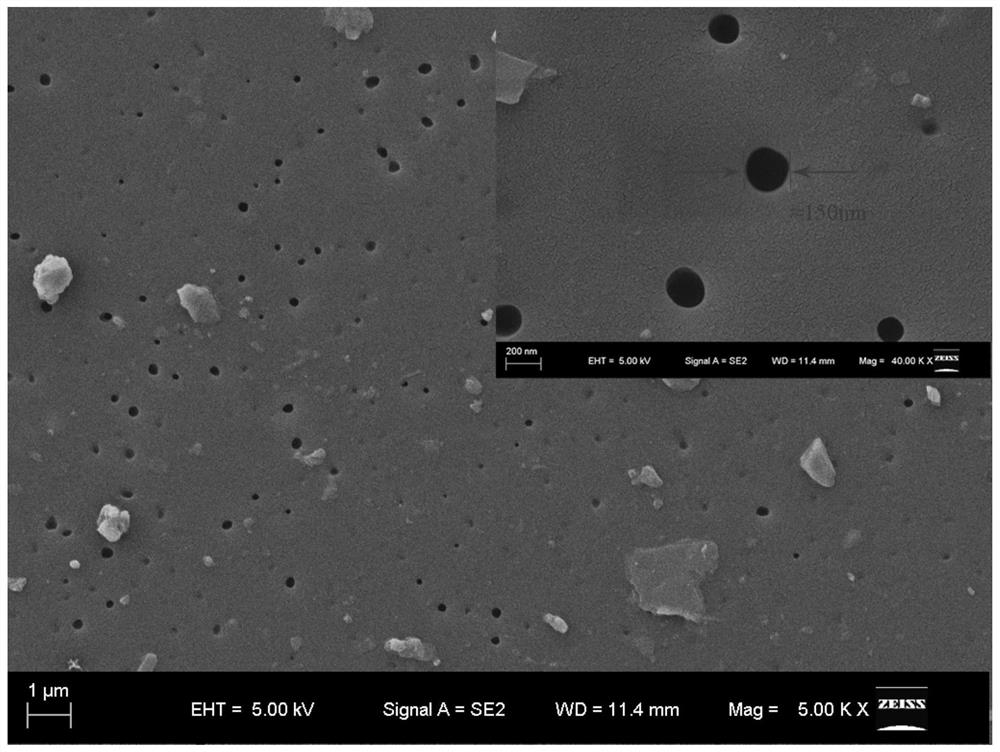

[0058] Take 0.1g of carbon nitride powder synthesized from urea and place it in 8g of DMF (N,N-dimethylformamide), stir it thoroughly with a magnetic stirrer for 30-60min, then use a 600W ultrasonic cleaner and continue ultrasonication for 6h to obtain carbon nitride suspension. Put the prepared suspension in a magnetic stirrer, slowly add 2g of high molecular polymer thermoplastic polyurethane transparent granules (TPU), continue stirring for 6 hours to obtain a coating film repellent liquid containing photocatalyst carbon nitride, and leave it overnight for 24 hours to remove Gas precipitation. Then use double-sided tape to wrap 1.5 circles on both ends of the glass rod (the thickness of the coating is 200μm), take a piece of 20*20cm clean glass, drop the upper liquid onto the surface of the glass plate, and then use the glass rod to coat the film. Place the prepared film in a blast drying oven to dry at 60-70°C for 2 hours, at 80-90°C for 3 hours, at 125°C for 4 hours, and...

Embodiment 2

[0063] Change the amount of carbon nitride synthesized by urea in the coating film flooding liquid, respectively 0.05, 0.1, 0.25, 0.5wt%, and the others are the same as in Example 1. The SEM image of the finally prepared film is shown in Figure 5 , the content of a / b / c / d corresponding to carbon nitride in the figure is 0.05, 0.1, 0.25, 0.5wt%, respectively, and when the carbon nitride content is low, the surface carbon nitride content of 0.05wt% film material is insufficient, The surface of the material is not completely covered, and when the content is large, the 0.5wt% carbon nitride powder cannot be fully dispersed and suspended during the dispersion process, and it is the first to agglomerate between the carbon nitride powders to cause Figure 5 The block in d appears, and the block is caused by the agglomeration of a large number of small particles. Therefore, carbon nitride is preferably less than 0.5 wt% in the coating flooding liquid, and the content of 0.1 wt%~0.25 w...

Embodiment 3

[0066] The drying temperature in the third stage of film gradient drying was changed to 95° C. for 4 hours and 125° C. for 4 hours. Other experimental conditions were the same as in Example 1.

[0067] Figure 7 In a is the SEM image of the film dried at 95°C for 4 hours, and there are no large number of pores on the surface of the film. Figure 7 Middle b is the SEM image of the film dried at 125°C for 4 hours, and a large number of pores appear on the surface of the film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com