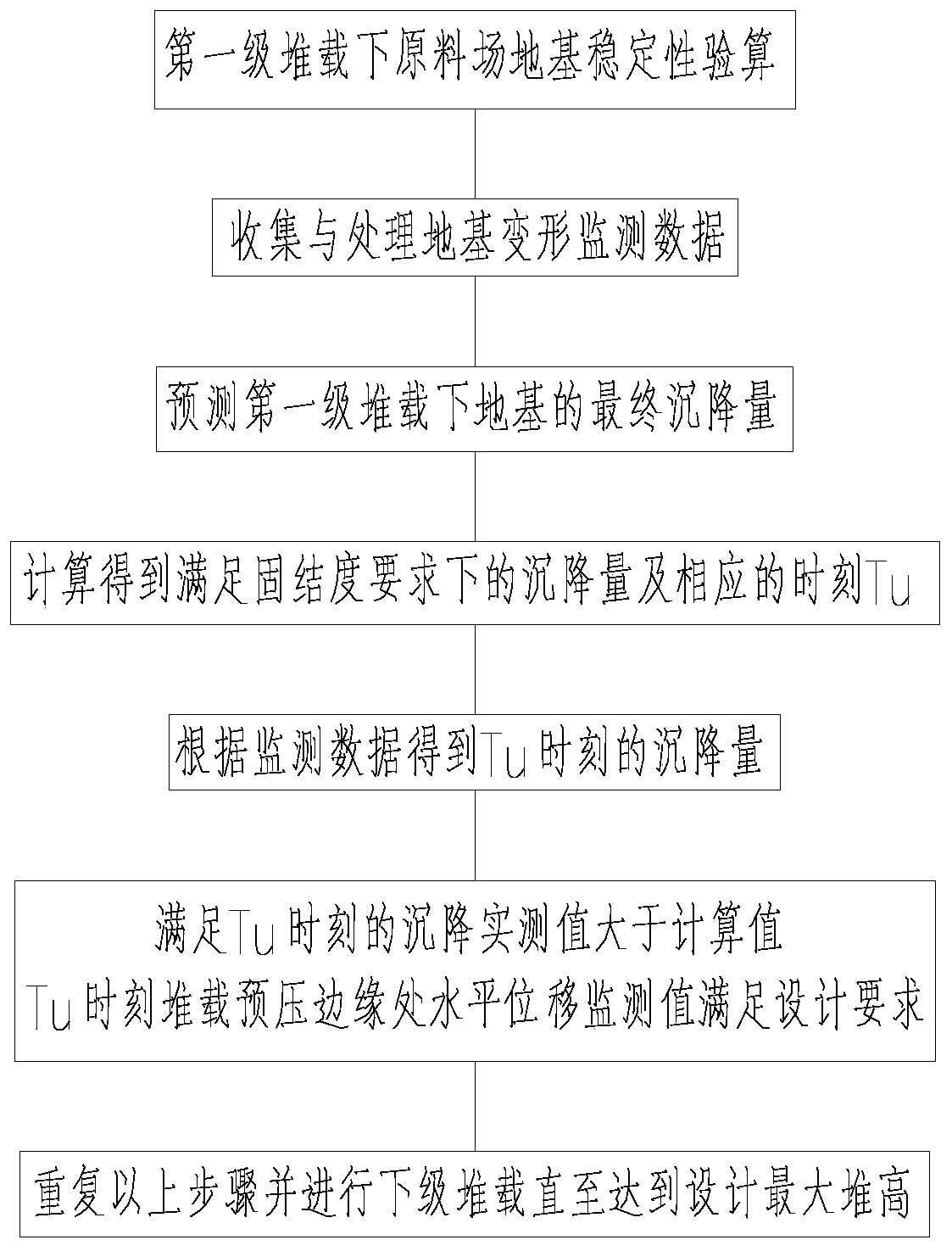

Large-area deep soft foundation graded filling construction stability control method

A technology with weak foundation and stable construction, which is applied in the fields of basic structure engineering, construction, on-site foundation soil survey, etc., can solve problems such as foundation soil instability and economic loss, and achieve cost saving, project investment cost saving, and project construction avoidance. The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

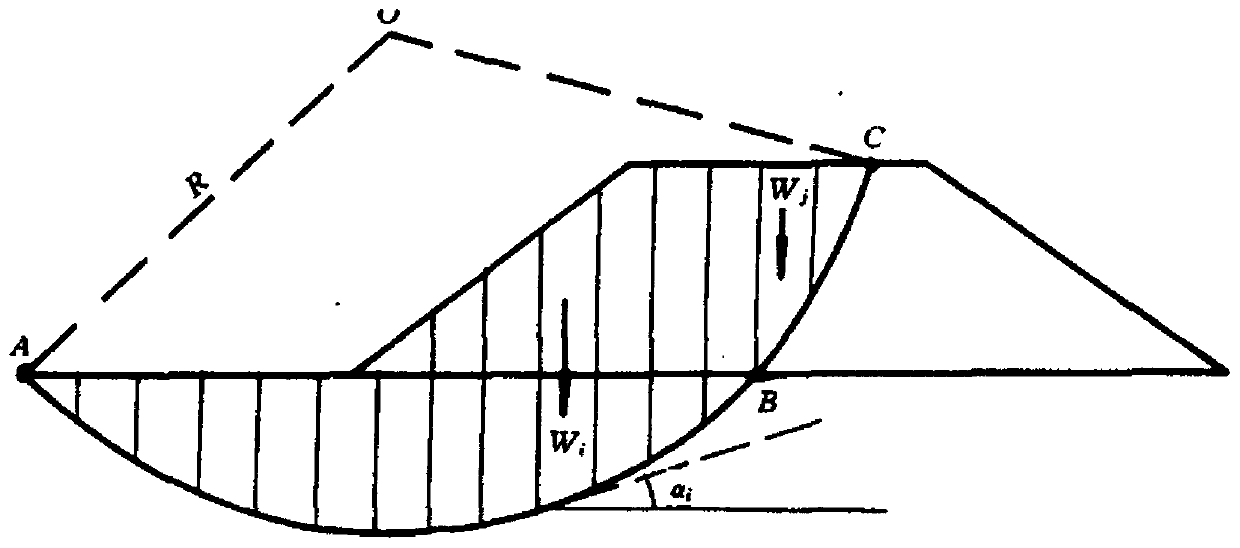

Method used

Image

Examples

Embodiment 1

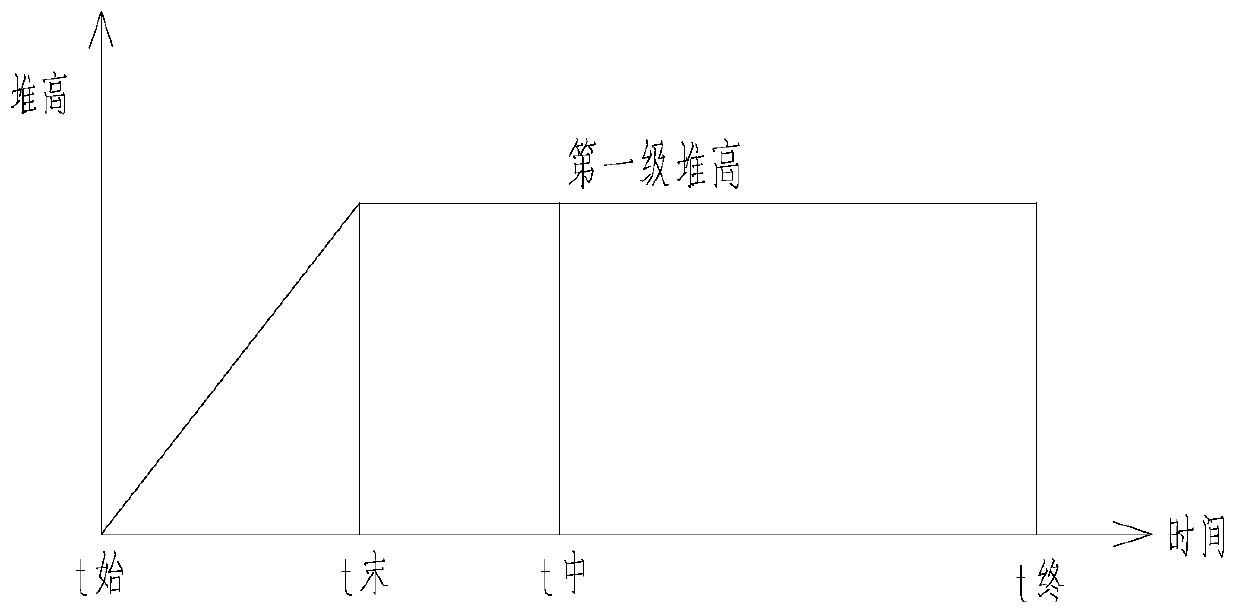

[0047] Embodiment 1 provides a method for controlling the stability of large-area deep, thick and soft foundation graded filling construction, which is specifically aimed at controlling the stability of a second-stage stockyard. The stockyard is close to the Yangtze River and is located on the first-level terrace on the right bank of the Yangtze River , divided into A, B, C, D four strips, the length, width and height of which are 350×50×13.8m 3 、350×48×13.0m 3 、350×48×13.0m 3 、350×35×12.25m 3 . Since most of the foundations of the stockyard are weak foundations, their bearing capacity cannot meet the design load requirements, and the stockyard foundation cannot meet the final ore stockpiling requirements at one time, so graded stockpiling is adopted, and the gravity of the ore powder is used to drain and consolidate the foundation soil to improve Its strength gradually meets the final heap height.

[0048] Among them, the stockyard A is adjacent to the Yangtze River, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com